- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HX

-

Voltage:

-

220V/380V/440V

-

Power:

-

5.5KW+1.5KW+4KW

-

Dimension(L*W*H):

-

5800*800*1200

-

Weight:

-

3.5 kg

-

Product name:

-

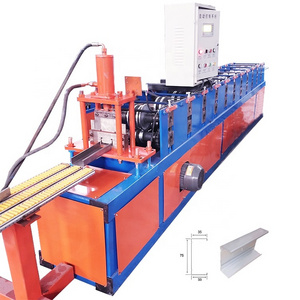

Steel Channel Making C Stud Roll Forming Machine

-

Raw material:

-

Steel Strip(galvanized strip and black strip)

-

Roller material:

-

Bearing steel with chromium plate

-

Shaft material:

-

Bearing steel Diameter: 50mm

-

Material thickness:

-

0.3mm-1.2mm

-

Cutting type:

-

Servo Motor Tracking Hydraulic Cutting

-

Main frame:

-

Square Box Steel Frame

-

Main Motor Power:

-

5.5KW+1.5KW+4KW

-

After Warranty Service:

-

Spare parts

-

After-sales Service Provided:

-

Free spare parts

Quick Details

-

Work Pressure:

-

190-350MPA

-

Production Capacity:

-

30 m/min-60m/min

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

HX

-

Voltage:

-

220V/380V/440V

-

Power:

-

5.5KW+1.5KW+4KW

-

Dimension(L*W*H):

-

5800*800*1200

-

Weight:

-

3.5 kg

-

Product name:

-

Steel Channel Making C Stud Roll Forming Machine

-

Raw material:

-

Steel Strip(galvanized strip and black strip)

-

Roller material:

-

Bearing steel with chromium plate

-

Shaft material:

-

Bearing steel Diameter: 50mm

-

Material thickness:

-

0.3mm-1.2mm

-

Cutting type:

-

Servo Motor Tracking Hydraulic Cutting

-

Main frame:

-

Square Box Steel Frame

-

Main Motor Power:

-

5.5KW+1.5KW+4KW

-

After Warranty Service:

-

Spare parts

-

After-sales Service Provided:

-

Free spare parts

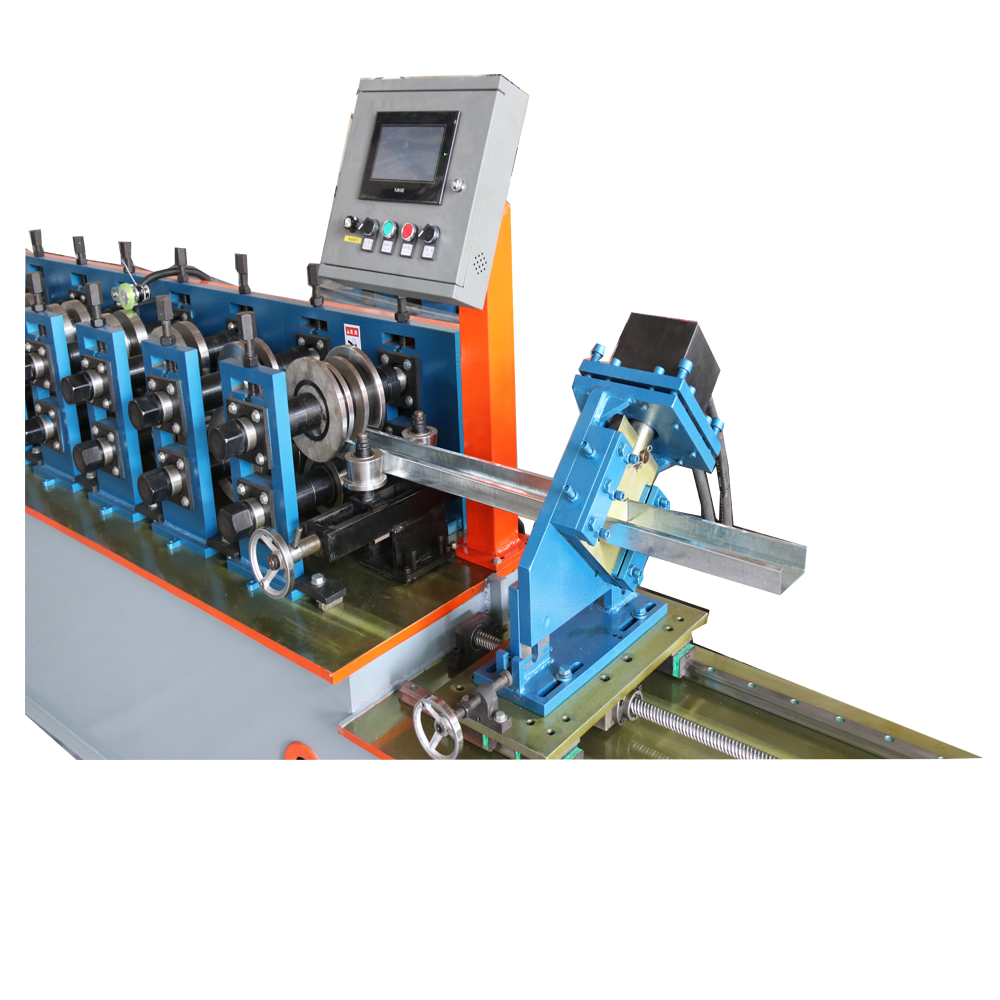

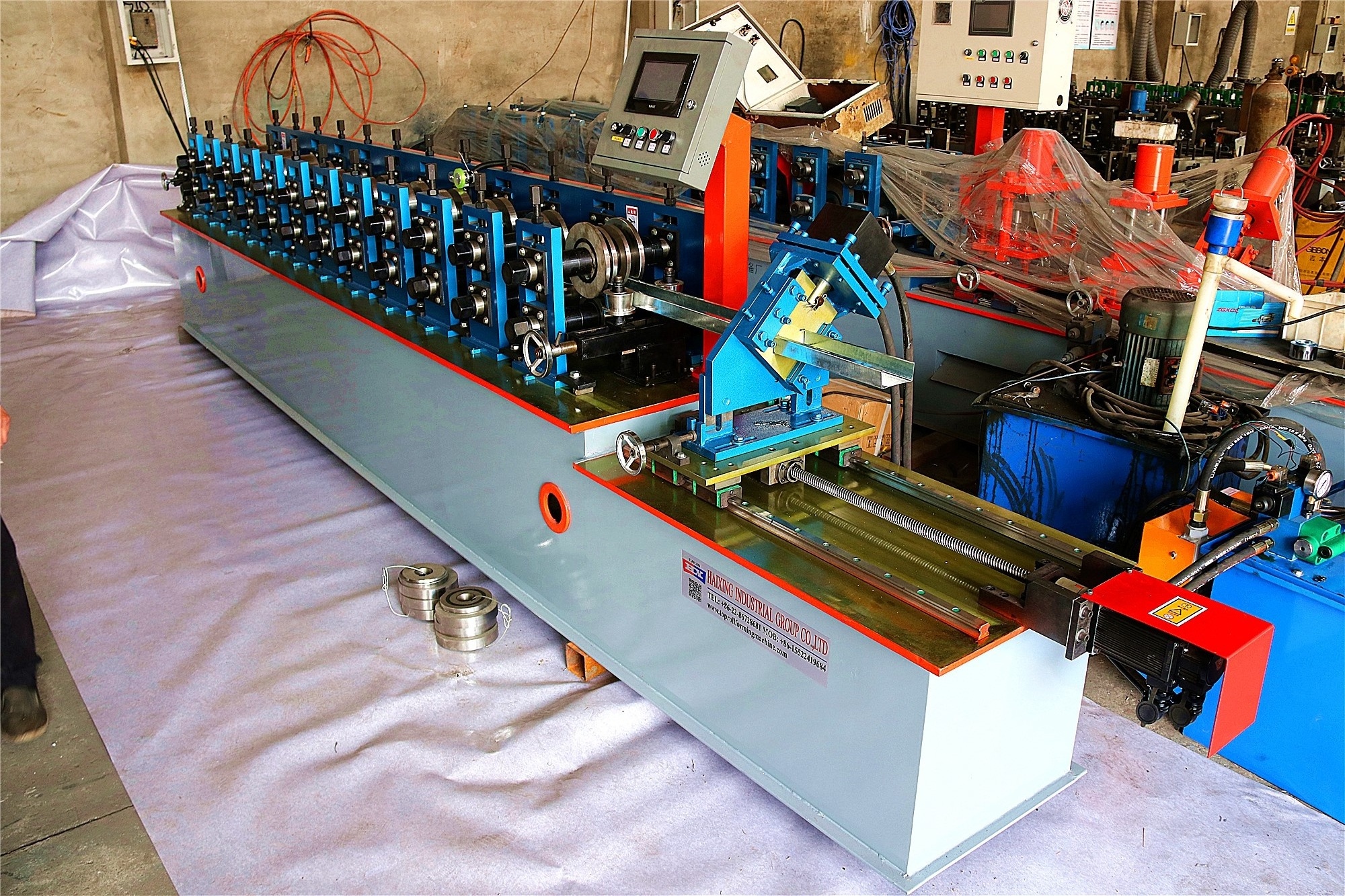

Steel Channel Making C Stud Roll Forming Machine

Steel Channel Making C Stud Roll Forming Machine

|

Detailed technical parameters |

|

|

Product Name |

Steel Channel Making C Stud Roll Forming Machine

|

|

Brand |

HX |

|

Type |

#HX Steel Channel Making C Stud Roll Forming Machine

|

|

Model and Raw material |

|

|

Base material |

Steel Strip (galvanized strip or black strip) |

|

Thickness |

0.3mm-1.2mm |

|

Effective Width |

U shape (width Customizable) |

|

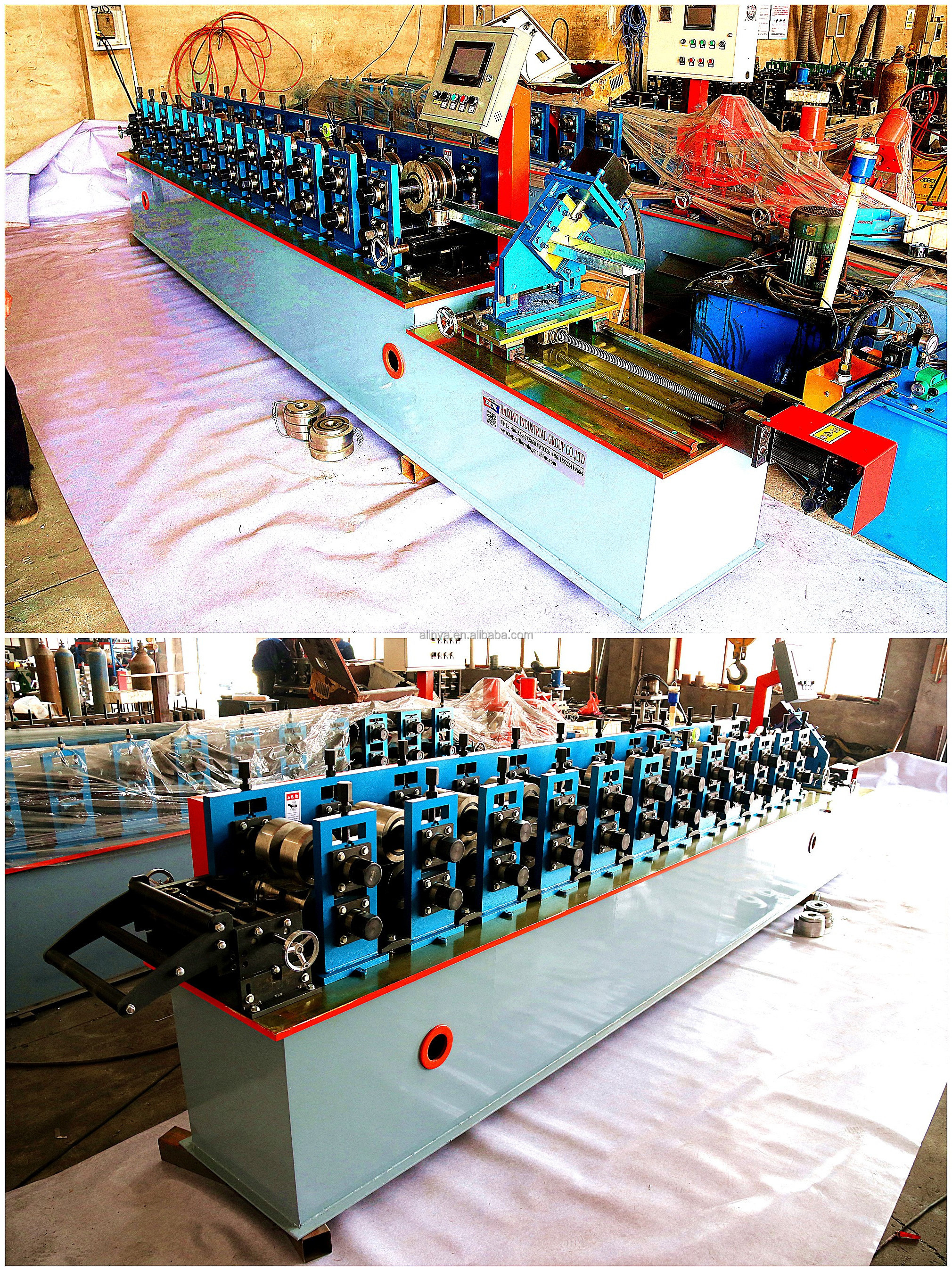

Roll Forming machine Components Details |

|

| Size | 5800*800*1200mm |

|

Weight |

3.5Tons |

|

Square box steel frame |

|

|

Side Panel Of Machine |

Memorial arch style |

|

Color |

All colors(Customized) |

|

Rollers |

14 rollers |

|

Roller material |

Bearing steel Cr12 Mov HRC 58-62 |

|

Diameter Of The Shaft |

Φ50mm |

| Chain Wheel and Cycle Chain Length:1 Inch | |

| Productivity |

30-60m/min |

|

Roll Forming machine Electric Components |

|

|

Voltage |

380V 50Hz 3phases(Can be customized according to local voltage) |

|

Motor power |

5.5KW |

|

Cutting&Hydraulic |

Type: Servo motor tracking + Hydraulic Cutting Servo motor tracking :1.5KW Hydraulic pump station : 4KW Blade: Cr12 Mov HRC 58-62 |

|

Control System |

PLC Electronic control cabinet |

| Screen | Touch Control system with multiple languages |

| Frequency Converter | Regular Brand:Delta |

| Feature | Famous Brand, Multi-Purpose, Easy to Operation, Full Automatic Computer Control, long S ervice L ife |

Steel Channel Making C Stud Roll Forming MachineAdvantage:

1. Famous Brand, quality is guaranteed.

2. Full Automatic Computer Control make easy to operation.

3. Machine roller and shaft is produced by exact demands and control . The roller material processing method is by CR12 MOV heat treatment 58 ℃-62 ℃ . The product quality is durable and long service life .

Working Flow and Main parts of Steel Channel Making C Stud Roll Forming Machine

|

Name: Manual Uncoiler

Brand: HX

Usage:It is used to support the steel Strip and uncoil it in a turnable way. The steel strip is uncoiled by hand.

Loading capacity:1.5T

Inner diameter: 470mm-530mm |

|

Feeding table:

The feeding table with a hand cutting.

During the operation of the machine, raw materials can be cut off in advance at the feeding position to avoid waste of raw materials.

The metal sheet is manually put on the feeding table. The metal sheet can be smoothed and leveled |

|

|

Roller and Shaft:

Roller Material: bearing steel

The roller material processing method :

Shaft Diameter: 50 mm

The roller and shaft won't scratch the board. It is long service life and durable.

|

|

Main Motor:

Brand:Lichao

|

|

|

|

Hydraulic Pump:

The pump power:4 KW

Brand: Lichao

Motor with pump capacity of tank: 45L

Hydraulic pump station provide cutting power

|

|

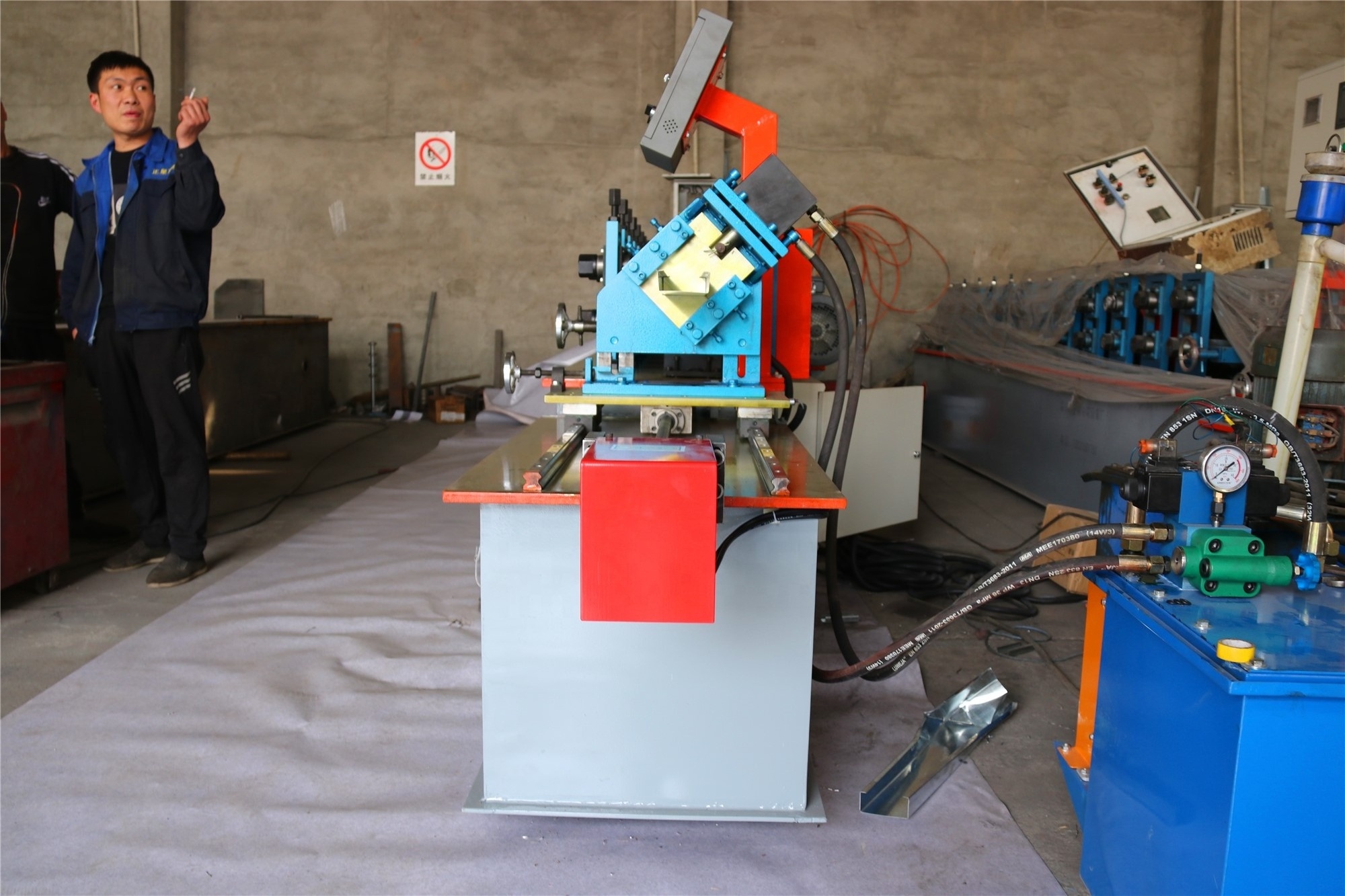

Servo motor tracking +Hydraulic Cutting:

Servo motor :1.5KW

Blade material: Cr12, heat treatment58 ℃-62 ℃

Servo motor drives cutting head to move. When cutting start to work, Hydraulic pump station excitation guide column working, drive blade cutting .

Because this cutting method is stable, metal plate cross section is neat.the cutting speed is increased. |

|

|

|

PLC electronic control system Brand : Delta

Touch Screen electronic panel Brand : DELTA

Touch design with multilingual function

It is to used to setting the cutting size with easy to operation |

Our products are used to produce in roof and wall building. It can be used in factories, houses, schools, hotels, shops and other construction sites.

Shipping:

1. It would be load one 20/40 feet container .

2. We have professional technicians for loading to make sure machine has no damage.

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

Advantage of the service:

1. Provides engineering drawing design services

2.Provide machine customization service

3.Remote video service

4.Engineer on-the- spot installation service

5. Help customers booking shipping service

6.Help customers purchase raw materials service

1.Payment Term: 30% paid by T/T as down payment, the rest 70% after inspection by buyer in seller’s factory while before delivery.

2.Delivery Time: We guarantees the equipment will be ready for shipment within 30 working days after receipt of deposit .

3.After sale Service: We could send technician to your country to install machine if you need. The buyer need to pay for all the cost, including: visa, round trip tickets, accommodation, salary of USD 100~120 per day.

4.Warranty: 2years