- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1430*1310*1340mm

-

Weight:

-

3000 KG

-

Marketing Type:

-

New Product

-

Product name:

-

Jaw Crusher Machine

-

Keyword:

-

Limestone jaw crusher

-

The Machines classification:

-

Stone Crushing Equipment

-

Crusher type:

-

Primary Coarse Jaw Crusher

-

Processed Materials:

-

200 Kinds Materials(<300 Mpa)

-

Max feeding size(mm):

-

200

-

Discharge size(mm):

-

20-50

-

Eccentric shaft speed(r/min):

-

300

-

Wearing parts:

-

Jaw board

-

Price:

-

Negotiatable

Quick Details

-

Application:

-

Construction works , Energy & Mining

-

Place of Origin:

-

Henan China

-

Brand Name:

-

Shunxiang

-

Dimension(L*W*H):

-

1430*1310*1340mm

-

Weight:

-

3000 KG

-

Marketing Type:

-

New Product

-

Product name:

-

Jaw Crusher Machine

-

Keyword:

-

Limestone jaw crusher

-

The Machines classification:

-

Stone Crushing Equipment

-

Crusher type:

-

Primary Coarse Jaw Crusher

-

Processed Materials:

-

200 Kinds Materials(<300 Mpa)

-

Max feeding size(mm):

-

200

-

Discharge size(mm):

-

20-50

-

Eccentric shaft speed(r/min):

-

300

-

Wearing parts:

-

Jaw board

-

Price:

-

Negotiatable

Products Description

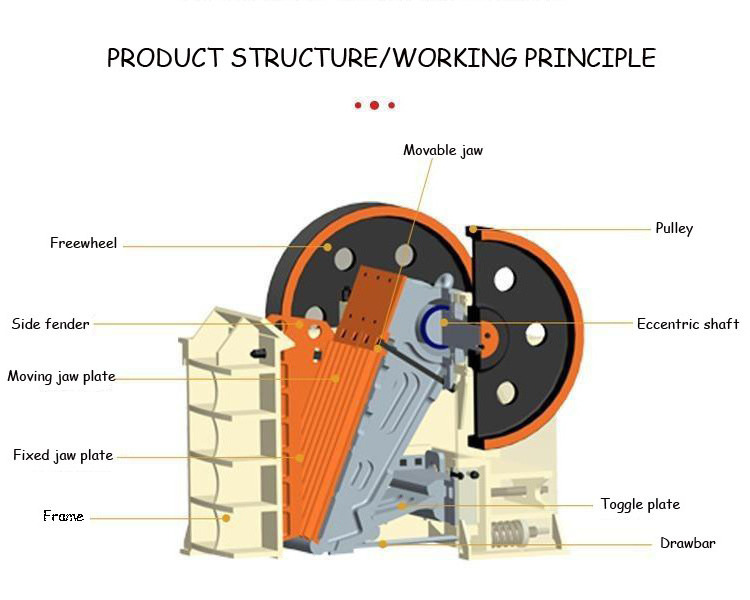

Jaw Crusher, also known is a crusher composed of two jaw plates, a moving jaw and a stationary jaw, which simulates the movement of two jaws of an animal to complete the crushing operation of the material. Simple structure, easy manufacture and reliable work.

Mobile jaw crusher

1. It is set on a frame with wheels that can be moved easily, making it flexible.

2. With its compact structure, simple operation, and high crushing ratio, it is very popular among small mining plants worldwide.

3. With Mn plates, strong supporting legs and wearable wheels, it has a long life and helps save on maintenance costs.

A jaw crusher uses compressive force for breaking of particle. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates. A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw, called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber. The movement of the swing jaw can be quite small, since complete crushing is not performed in one stroke. The inertia required to crush the material is provided by a weighted flywheel that moves a shaft creating an eccentric motion that causes the closing of the gap.

The PE series jaw crusher is widely applied in mine, metallurgy,chemical industry, building, highway,water conservancy, light industry to crush or break various kinds of stones with compressive of not more than 350Mpa

|

More models

|

|

|

|

|

|

|

||||||

|

Model

|

Max Feeding Size (mm)

|

Discharge

Opening

(mm)

|

Capacity

(tph)

|

Motor

(kW)

|

Weight

(t)

|

Overall Dimension

(mm)

|

||||||

|

PE150x250

|

125

|

10-40

|

1-3

|

5.5

|

0.8

|

720x660x850

|

||||||

|

PE 200x300

|

180

|

15-50

|

2-6

|

7.5

|

1.2

|

910x750x990

|

||||||

|

PE200x350

|

180

|

18-70

|

3-10

|

11

|

1.5

|

1000x870x990

|

||||||

|

PE250×400

|

210

|

20-60

|

5-20

|

15

|

2.8

|

1300×1090×1270

|

||||||

|

PE400×600

|

340

|

40-100

|

16-60

|

30

|

7

|

1730×1730×1630

|

||||||

|

PE500×750

|

425

|

50-100

|

40-110

|

55

|

12

|

1980×2080×1870

|

||||||

|

PE600×900

|

500

|

65-160

|

90-180

|

55

|

17

|

2190×2206×2300

|

||||||

|

PE750×1060

|

630

|

80-140

|

110-320

|

110

|

29

|

2660×2430×2800

|

||||||

|

PE800×1060

|

640

|

80-150

|

130-330

|

110

|

29.8

|

2710×2430×2800

|

||||||

|

PE900×1060

|

685

|

80-150

|

230-390

|

110

|

33

|

2870×2420×2940

|

||||||

|

PE900×1200

|

750

|

95-165

|

220-450

|

110-132

|

58

|

3380×2870×3330

|

||||||

|

PE1000×1200

|

850

|

195-265

|

315-500

|

110-160

|

69

|

3480×2876×333

|

||||||

|

PE1200×1500

|

1020

|

150-300

|

400-800

|

160-220

|

100.9

|

4200×3300×3500

|

||||||

|

PEX150×750

|

125

|

18-48

|

5-16

|

15

|

3.8

|

1200×1500×1200

|

||||||

|

PEX250×750

|

210

|

25-60

|

15-30

|

22-30

|

5

|

1667×1545×1020

|

||||||

|

PEX250×1000

|

210

|

25-60

|

15-50

|

30-37

|

7

|

1550×1946×1380

|

||||||

|

PEX250×1200

|

210

|

25-60

|

20-60

|

37-45

|

8.5

|

2192×1900×1950

|

||||||

|

PEX300×1300

|

250

|

20-90

|

30-90

|

55-75

|

11.5

|

1750×2320×1724

|

||||||

Product Display

* Accessories customization service

Our jaw crusher is made of high manganese steel, has very high wear resistance, which can extend the service life of wearing parts and help customers reduce costs. The machine body and the welding area are polished very smoothly, and the painting is also very uniform, so the overall appearance of the machine is very beautiful. If you buy our machine, we can give you a 5% discount of the spare parts.

Customer Site

Our Services

We have a strict quality control system in place throughout the entire production process, so our products are all of the highest quality and reliability. We also offer OEM service upon request. If you have a need for any mining equipment, or related spare parts, please feel free to contact us. We are dedicated to serving each of our customers to their complete satisfaction.

About Shunxiang

Henan Shunxiang Machinery Co., Ltd is a company that integrates science, industry and trade. The company mainly produces and sells mechanical equipment and accessories, including jaw crushers, hammer crushers, roller crushers, and screening and conveying equipment. It can also customize stone and sand production lines.

Our company's products with the advanced technology, reliable quality and reasonable price. We have also got the good reputations from customers at home and abroad.

FAQ

Q1: How will you help customers install devices?

A: Our senior engineers will provide installation and training services online or on-site.

Q2: If you would like us to recommend suitable types and the best quotation for you, please let us know as follows:

1) What are your raw materials?

2) How much production do you need per hour? 50 tons/hour, 100 tons/hour, 150 tons/hour, and 200 tons/hour.

3) What is the maximum size of raw materials (millimeters/inches)?

4) What is the required output size?

Q3: How long is the warranty period? Does your company provide relevant spare parts?

A: The warranty period for the equipment is one year. We provide spare parts at a reasonable price.

Q4: How long is the delivery time?

A: If the goods are in stock, it usually takes one week. Otherwise, it will take 15-20 days, depending on the quantity ordered and the type of customization.

Q5: Can I visit your factory?

A: We warmly welcome you to visit our factory. We will take you to our factory for a real inspection. We will arrange a car to pick you up at the airport.

Hot Searches