- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

auris

-

Voltage:

-

380V/Customized

-

Power:

-

34KW

-

Weight:

-

2600 kg

-

Product name:

-

Pulp Egg Tray Machine

-

System:

-

pulping,molding,drying,packing

-

Finished Products:

-

paper egg tray, shoe tree, fruit tray,industrial packaging

-

Mould:

-

Aluminum mold and plastic mold

Quick Details

-

Production Capacity:

-

1000 pcs/h

-

Product Type:

-

Paper product Making Machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

auris

-

Voltage:

-

380V/Customized

-

Power:

-

34KW

-

Weight:

-

2600 kg

-

Product name:

-

Pulp Egg Tray Machine

-

System:

-

pulping,molding,drying,packing

-

Finished Products:

-

paper egg tray, shoe tree, fruit tray,industrial packaging

-

Mould:

-

Aluminum mold and plastic mold

Product Description

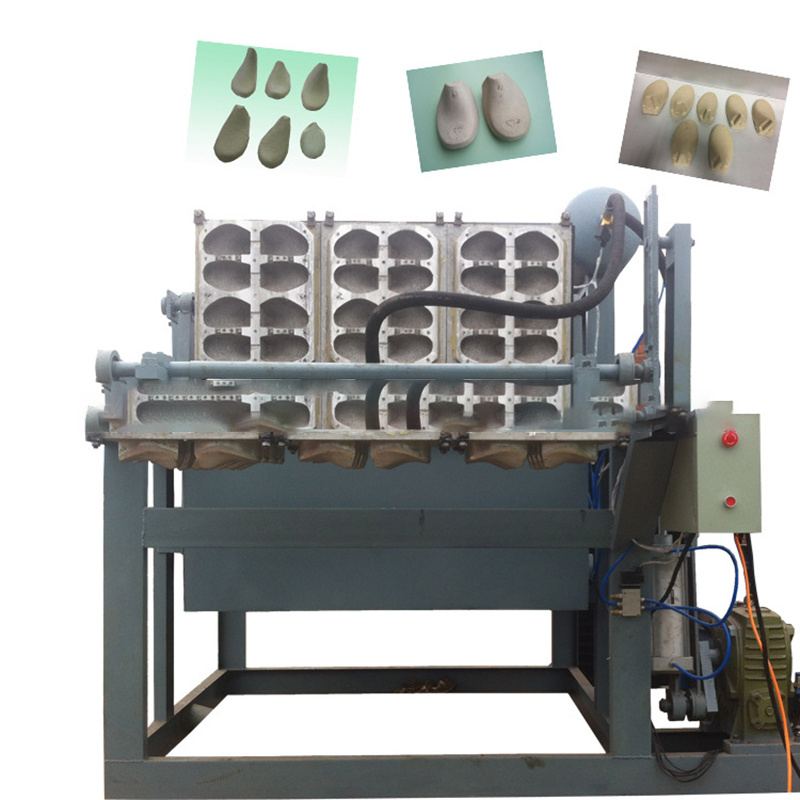

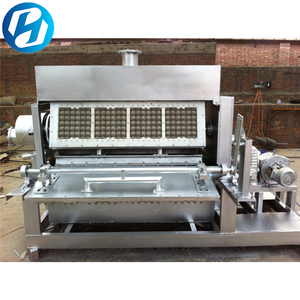

Coffee Tray Making Machine Rotating Paper Egg Tray Machine Shoe Holder Machine Paper

Equipment process flow

1. Pulping system

(1) Put the raw material into the pulping machine, add an appropriate amount of water, and stir it for a long time to turn the waste paper into pulp, and then put it into the pulp storage tank for storage.

(2) Put the pulp in the pulp storage tank into the pulp mixing tank, and adjust the pulp concentration in the pulp mixing tank.The slurry is further stirred through a homogenizer. After adjusting to suitable pulp, put it into the pulp supply tank to be used in the forming system.

2. Forming system

(1) The pulp in the pulp supply pool is fed into the forming machine, and absorbed by the vacuum system, the pulp is passed through the mold on the equipment and the pulp is left in the mold

It is formed on the tool, and the white water is adsorbed and transferred back to the pool by the vacuum pump.

(2) After the mold is adsorbed, the transfer mold passes through the positive pressure of the air compressor, and the molded product is blown from the molding mold to the rotating mold.Sent from the transfer mold.

3. Drying system

(1) Natural drying method: directly rely on the weather and natural wind to dry the product.

(2) Traditional drying: brick-built tunnel kiln, the heat source can choose natural gas, diesel, coal, dry wood, liquefied petroleum gas and other heat sources.

(3) New multi-layer drying line: 6-layer metal drying line can save more than 30% energy than transmission drying, and the main heat source is natural gas, diesel, Clean energy such as liquefied petroleum gas and methanol.

4. Auxiliary packaging of finished products

(1) Automatic stacker

(2) Baler

(3) Transfer conveyor

1. Pulping system

(1) Put the raw material into the pulping machine, add an appropriate amount of water, and stir it for a long time to turn the waste paper into pulp, and then put it into the pulp storage tank for storage.

(2) Put the pulp in the pulp storage tank into the pulp mixing tank, and adjust the pulp concentration in the pulp mixing tank.The slurry is further stirred through a homogenizer. After adjusting to suitable pulp, put it into the pulp supply tank to be used in the forming system.

2. Forming system

(1) The pulp in the pulp supply pool is fed into the forming machine, and absorbed by the vacuum system, the pulp is passed through the mold on the equipment and the pulp is left in the mold

It is formed on the tool, and the white water is adsorbed and transferred back to the pool by the vacuum pump.

(2) After the mold is adsorbed, the transfer mold passes through the positive pressure of the air compressor, and the molded product is blown from the molding mold to the rotating mold.Sent from the transfer mold.

3. Drying system

(1) Natural drying method: directly rely on the weather and natural wind to dry the product.

(2) Traditional drying: brick-built tunnel kiln, the heat source can choose natural gas, diesel, coal, dry wood, liquefied petroleum gas and other heat sources.

(3) New multi-layer drying line: 6-layer metal drying line can save more than 30% energy than transmission drying, and the main heat source is natural gas, diesel, Clean energy such as liquefied petroleum gas and methanol.

4. Auxiliary packaging of finished products

(1) Automatic stacker

(2) Baler

(3) Transfer conveyor

Specification

|

item

|

value

|

|

Applicable Industries

|

Manufacturing Plant

|

|

Showroom Location

|

None

|

|

Condition

|

New

|

|

Product Type

|

Paper product Making Machine

|

|

Processing Type

|

Pulp Molding Machine

|

|

Place of Origin

|

China

|

|

|

Henan

|

|

Brand Name

|

auris

|

|

Voltage

|

380V/Customized

|

|

Power

|

34KW

|

|

Dimension(L*W*H)

|

|

|

Weight

|

2600kg

|

|

Warranty

|

1 Year

|

|

Production Capacity

|

1000 pcs/h

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Marketing Type

|

Ordinary Product

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Engine, Motor, Pump, Bearing, Gearbox

|

|

Product name

|

Pulp Egg Tray Machine

|

|

System

|

pulping,molding,drying,packing

|

|

Finished Products

|

paper egg tray, shoe tree, fruit tray,industrial packaging

|

|

Mould

|

Aluminum mold and plastic mold

|

Hot Searches