- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

YGW Biomass/Coal Fired Thermal Oil Boiler

-

Keywords:

-

Thermal Oil Boiler

-

Material:

-

Special Boiler Steel Plate

-

Application:

-

Industrial Production

-

Application Field:

-

Building Materials

-

Function:

-

Multifunctional

-

Color:

-

Customers Requirment

-

Operation:

-

Easy Operation

-

Applicable Fuel:

-

Coal-fired Biomass

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Steam Production:

-

0

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhongde

-

Product name:

-

YGW Biomass/Coal Fired Thermal Oil Boiler

-

Keywords:

-

Thermal Oil Boiler

-

Material:

-

Special Boiler Steel Plate

-

Application:

-

Industrial Production

-

Application Field:

-

Building Materials

-

Function:

-

Multifunctional

-

Color:

-

Customers Requirment

-

Operation:

-

Easy Operation

-

Applicable Fuel:

-

Coal-fired Biomass

-

Marketing Type:

-

Ordinary Product

Product Description

Characteristics of Zhongde YGW furnace type

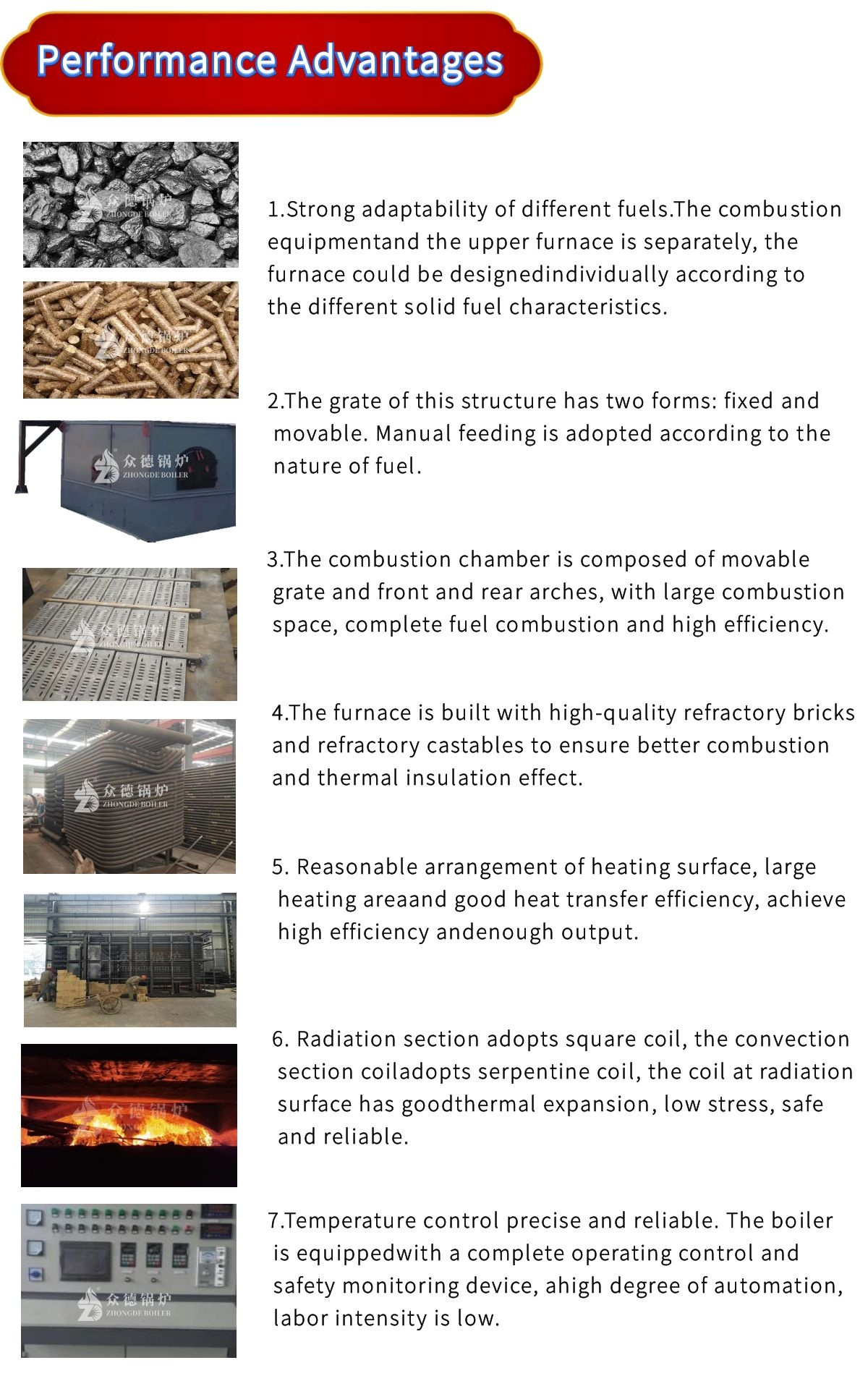

1. Strong adaptability to different fuels

The combustion equipment is designed separately from the upper furnace body, and the furnace structure can be designed separately according to the different properties of solid fuel;

2. Diversity of grate structure

The grate of this structure has two forms: fixed and movable. According to the nature of fuel, manual or mechanical feeding can be adopted.

3. Square coil combustion chamber

The boiler combustion chamber is composed of refractory furnace chamber and square coil tube, with sufficient fuel combustion space, complete combustion and high thermal efficiency.

4. Best coil design

The radiation section is made of square coil tube and the convection section is made of serpentine tube. The heating surface tube has good thermal expansion performance, low stress, safety and reliability.

5. Best process design

The flue gas has three returns, the medium flows through the convection and radiation coil, the flow rate is uniform, and the operation is safe and stable.

6. Sufficient output

The heating surface is reasonably arranged, with large area, good heat transfer effect, high efficiency, stable and sufficient output.

7. Improvement of automatic control measures

The oil outlet temperature is controlled accurately, and multiple control protection is set for medium temperature, pressure and over smoke temperature to ensure safe and reliable operation.

8. The level of automatic control is leading

The boiler controller adopts Siemens / Delixi electrical components with reliable performance. The controller has three forms: ordinary type, Chinese and English menu type with liquid crystal display, and touch screen type with man-machine dialogue and remote control. The standard configuration is ordinary type.

Model YGW Rated Thermal Power 1200-4700 KW

Design Pressure 1.1 Mpa

Working Pressure 0.8 Mpa

Medium Outlet Temperature ≤350 ℃

Solid fuels such as coal, biomass particles, sawdust, wood blocks, palm shells and rice husks can be used

Solid fuels such as coal, biomass particles, sawdust, wood blocks, palm shells and rice husks can be used

Application Chemical,Oil,Petrochemical,Textile,Printing,Rubber,Carton,Plywood,Asphalt,Cement, etc

Product Datasets

|

MODEL

|

YGW-1400MA

|

YGW-1800MA

|

YGW-2100MA

|

YGW-2400MA

|

YGW-3000MA

|

YGW-3500MA

|

YGW-4200MA

|

YGW-4700MA

|

|||||||

|

Rated power(KW)

|

1400

|

1800

|

2100

|

2400

|

3000

|

3500

|

4200

|

4700

|

|||||||

|

Design pressure(Mpa)

|

1.1

|

|

|

|

|

|

|

|

|||||||

|

Rated working pressure(Mpa)

|

0.8

|

|

|

|

|

|

|

|

|||||||

|

Highest working temperature(℃)

|

<350

|

|

|

|

|

|

|

|

|||||||

|

Furnace oil volume(m3/h)

|

1.2

|

1.5

|

1.9

|

2.1

|

2.4

|

3.8

|

4.2

|

4.6

|

|||||||

|

Circulation oil

volume(m3/h) |

100

|

100

|

140

|

160

|

200

|

200

|

250

|

250

|

|||||||

|

Pipe connection diameter(DN)

|

125

|

150

|

150

|

150

|

150

|

200

|

200

|

200

|

|||||||

|

Thermal Efficiency (%)

|

~85

|

|

|

|

|

|

|

|

|||||||

|

Upper part Size (m)

|

4.1x2.48x2.83

|

4.55x2.6

x3.01

|

5.3x2.75

x2.7

|

6.15x2.75

x3.1

|

6.38x2.75x2.96

|

6.33x2.93

x3.02

|

7.65x3.1

x3.3

|

7.9x3.2

x3.7

|

|||||||

|

Lower part Size (m)

|

3.87x2.5

x1.5

|

4.2x2.65

x1.5

|

5x2.53

x1.5

|

5.5x2.82x1.8

|

5.88x2.86

x1.8

|

7.5x2.93

x1.8

|

6.9x3.2

x1.8

|

7.2x2.96

x1.8

|

|||||||

|

Weight (T)

|

14

|

17

|

22

|

24

|

27

|

28

|

31

|

35

|

|||||||

Product manufacturing process

Application & Boiler case

Applicable industry

Chemical industry, grease, petrochemical, textile, printing and dyeing, plastics, rubber, fiber, carbon, construction, cement, asphalt, metal, coating, wood processing, papermaking and printing, atomic energy industry, etc.

8 MKcal Heat transfer oil boiler

Fuel:

Waste wood, sanding powder

User’s site:

Malaysia

Capacity: 9400KW

Application:

wood industry

5 MKcal Heat transfer oil boiler

Fuel: Coal

User’s site:

Indonesia

Capacity: 6000KW

Application:

construction industry

4 MKcal Heat transfer oil boiler

Fuel:

Waste wood, sanding powder

User’s site:

South Africa

Capacity: 4700KW

Application:

wood industry

3 MKcal Heat transfer oil boiler

Fuel:

Waste wood, sanding powder

User’s site:

The Gabonese Republic

Capacity: 3500KW

Application:

Rubber industry

Hot Searches