- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

15

-

Weight (KG):

-

500

-

Application:

-

Waste Metal Shredder

-

Function:

-

Multifunctional Waste Material Shredder

-

Product name:

-

Multifunctional Shredder

-

Advantage:

-

High Efficiency Low Energy Consumption

-

Type:

-

Automation

-

Crushing material:

-

Waste Plastic Scrap Metal Crusher

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Application field:

-

Scrap Metal Processing Broken

-

After-sale Service:

-

Professional Technician

-

Machine name:

-

Single Shaft Shredder

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

Hot Product 2024

-

Brand Name:

-

YINJIANG

-

Power (kW):

-

15

-

Weight (KG):

-

500

-

Application:

-

Waste Metal Shredder

-

Function:

-

Multifunctional Waste Material Shredder

-

Product name:

-

Multifunctional Shredder

-

Advantage:

-

High Efficiency Low Energy Consumption

-

Type:

-

Automation

-

Crushing material:

-

Waste Plastic Scrap Metal Crusher

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Application field:

-

Scrap Metal Processing Broken

-

After-sale Service:

-

Professional Technician

-

Machine name:

-

Single Shaft Shredder

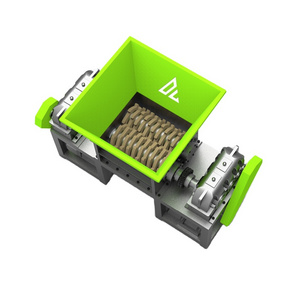

The single axis shredder can meet the waste recycling requirements of various industries, suitable for plastic, paper, wood, fiber, rubber, household waste recycling and treatment, and has a wide variety of recyclable materials. Suitable for recycling various large solid materials, difficult to handle materials, plastic containers and barrels, and plastic pads. The discharge size can be reduced to 20mm according to different needs. And we can provide various feeding hoppers according to customer needs. This device has low speed blade rotation, low noise, and is more economical.

|

model

|

Large, medium, and small

|

|

power

|

3-90kw

|

|

Reducer

|

200-850

|

|

speed

|

16-30r/min

|

Product Photograph

Product features:

1. Heavy moving knife with high crushing efficiency, and the tool is made of alloy steel casting, which is durable.

2. Thick frame plate, capable of resisting high torque, very strong.

3. Microcomputer automatic control, with start, stop, reverse, and overload automatic reverse control functions.

4. This device has the characteristics of low speed, high torque, and low noise.

5. Easy adjustment and low maintenance cost.

6.The thickness of the cutting tool and the number of claws can be changed according to different materials.

Working principle:

The material enters the chassis from the feeding hopper, and the pushing box is pushed by the hydraulic cylinder to push the material towards the rotating knife roller. The rotating knife and fixed knife crush the material, and the crushed material falls through the screen. Then, it is transported to the next process or collected and packaged through auxiliary conveying equipment. The material enters the inside of the shredding box through the feeding system, and there are shredding blades on the box. The pushing box pushes the material near the blades. The material is then torn into small pieces through the comprehensive effects of tearing, squeezing, and shearing by the shredding blades, and discharged from the sieve holes.

product mix

Scope of application

Display of crushing effect

Customer feedback

Service tenet:Integrity based management, To ensure quality control,Satisfy both parties。

FAQ

Q:Are you a trading company or a manufacturing factory?

A:We are a factory。

Q:What is your delivery time?

A:If the goods are in stock, it usually takes 7-10 days。

If the goods are out of stock, it will take 15 to 30 days, calculated by quantity。

Q:What is your payment method?

A:30% of the total price should be paid in T/T as the down payment; 70% of the remaining payment should be paid in T/T before delivery。

Q:Do you provide technical guidance?

A:Yes, we will provide you with professional advice on the selection of models and the operation of equipment。

Hot Searches