- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

3200 mm

-

Backgauge Travel (mm):

-

10 - 750 mm

-

Throat Depth (mm):

-

150 mm

-

Brand Name:

-

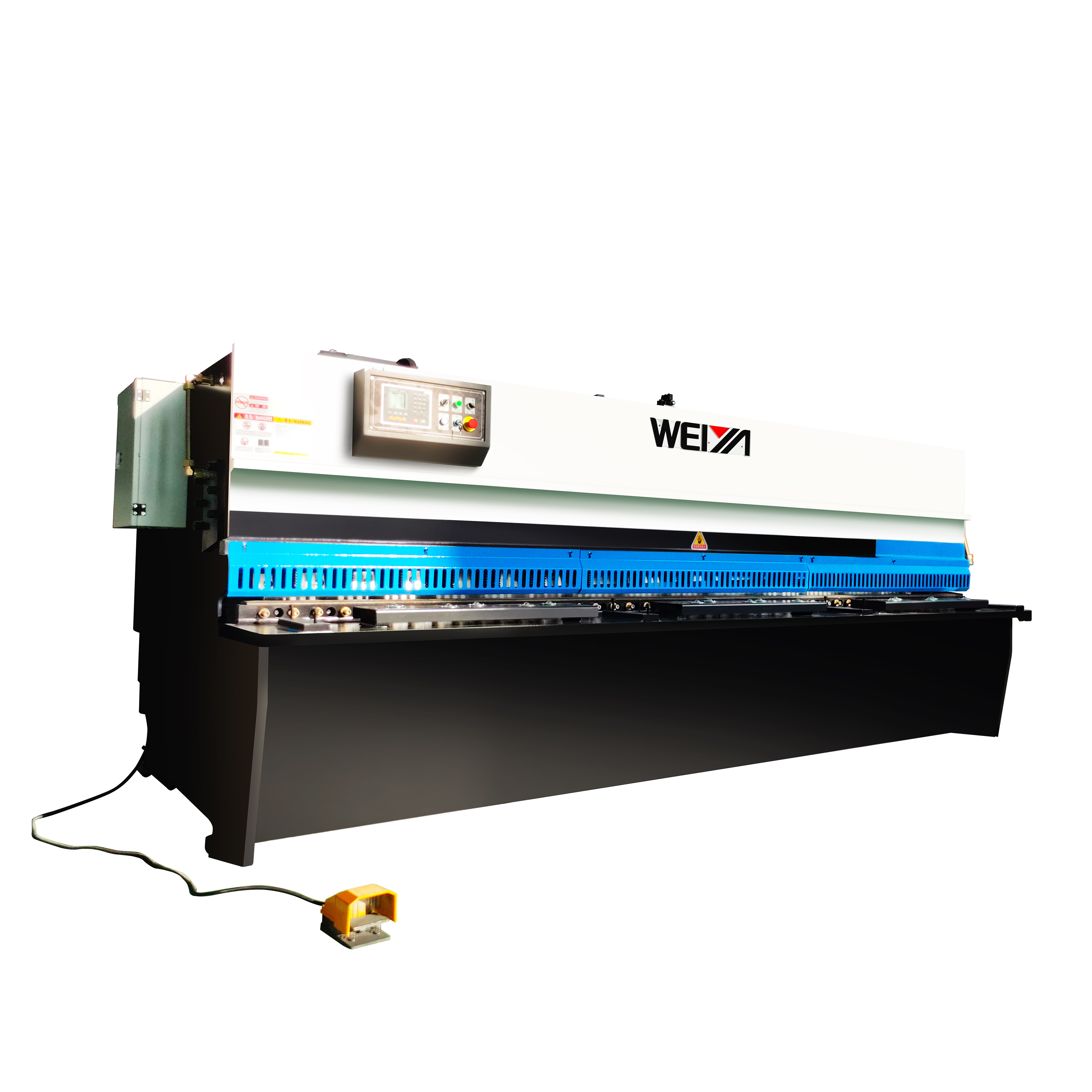

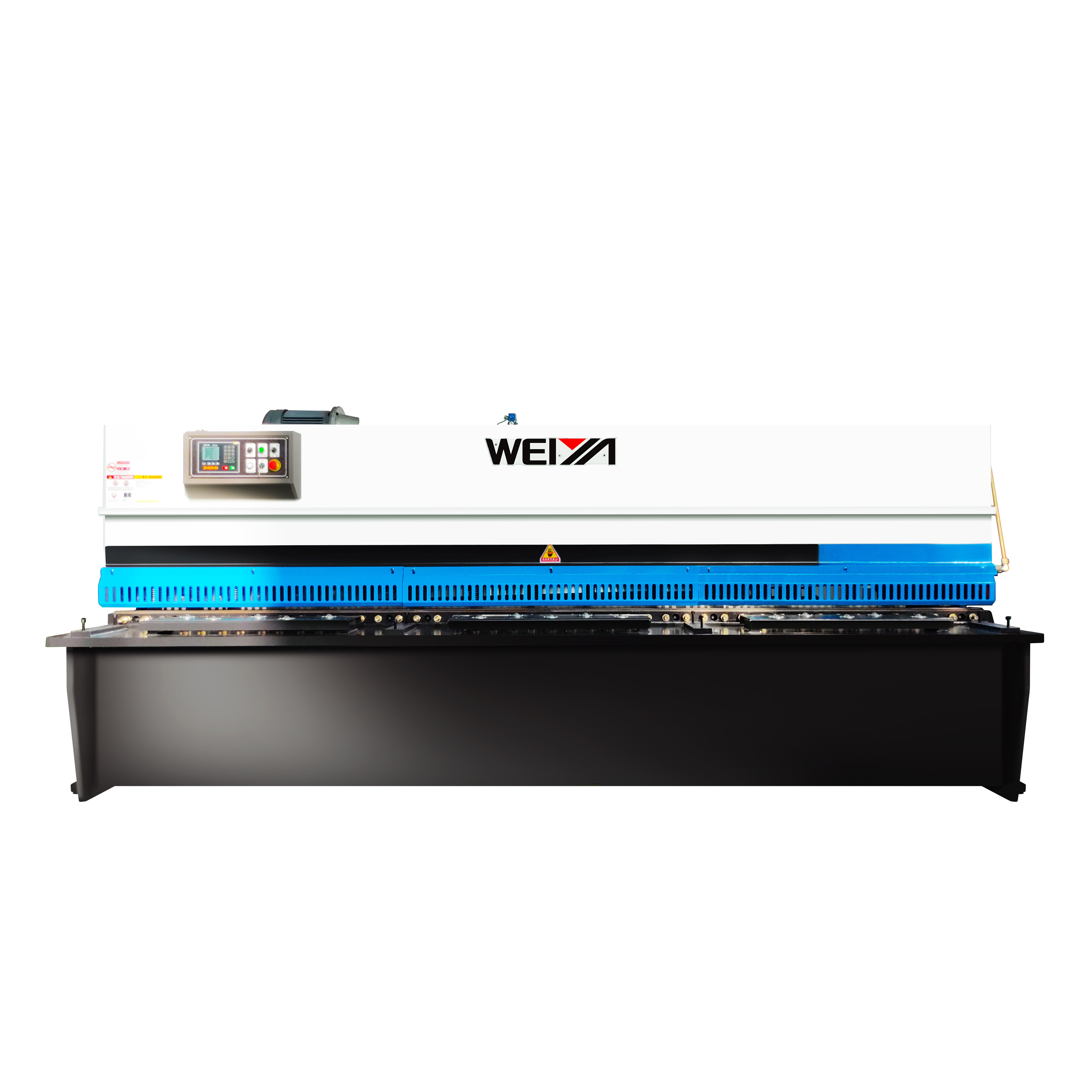

WEIYA

-

Power (kW):

-

18.5 kW

-

Weight (KG):

-

9.6 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

3950*2050*2300

-

Year:

-

2024

-

Marketing Type:

-

New Product 2024

-

Cutting material:

-

Metal .alloy Metal .aluminum

-

Cutting length:

-

3200mm Metal Shears

-

Cutting thickness:

-

12mm Metal Cutter

-

Throat depth:

-

150

-

Control system:

-

Estun

-

Function:

-

Metal Hydraulic Guillotine Shears

-

Hydraulic Valve:

-

Hoerbigger Swiss

-

Main Motor:

-

Siemens Germany

-

After-sales Service Provided:

-

Online Support

Quick Details

-

Max. Cutting Width (mm):

-

3200

-

Max. Cutting Thickness (mm):

-

12 mm

-

Shearing Angle:

-

2°, 0.5-2°

-

Blade Length (mm):

-

3200 mm

-

Backgauge Travel (mm):

-

10 - 750 mm

-

Throat Depth (mm):

-

150 mm

-

Brand Name:

-

WEIYA

-

Power (kW):

-

18.5 kW

-

Weight (KG):

-

9.6 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

3950*2050*2300

-

Year:

-

2024

-

Marketing Type:

-

New Product 2024

-

Cutting material:

-

Metal .alloy Metal .aluminum

-

Cutting length:

-

3200mm Metal Shears

-

Cutting thickness:

-

12mm Metal Cutter

-

Throat depth:

-

150

-

Control system:

-

Estun

-

Function:

-

Metal Hydraulic Guillotine Shears

-

Hydraulic Valve:

-

Hoerbigger Swiss

-

Main Motor:

-

Siemens Germany

-

After-sales Service Provided:

-

Online Support

Products Description

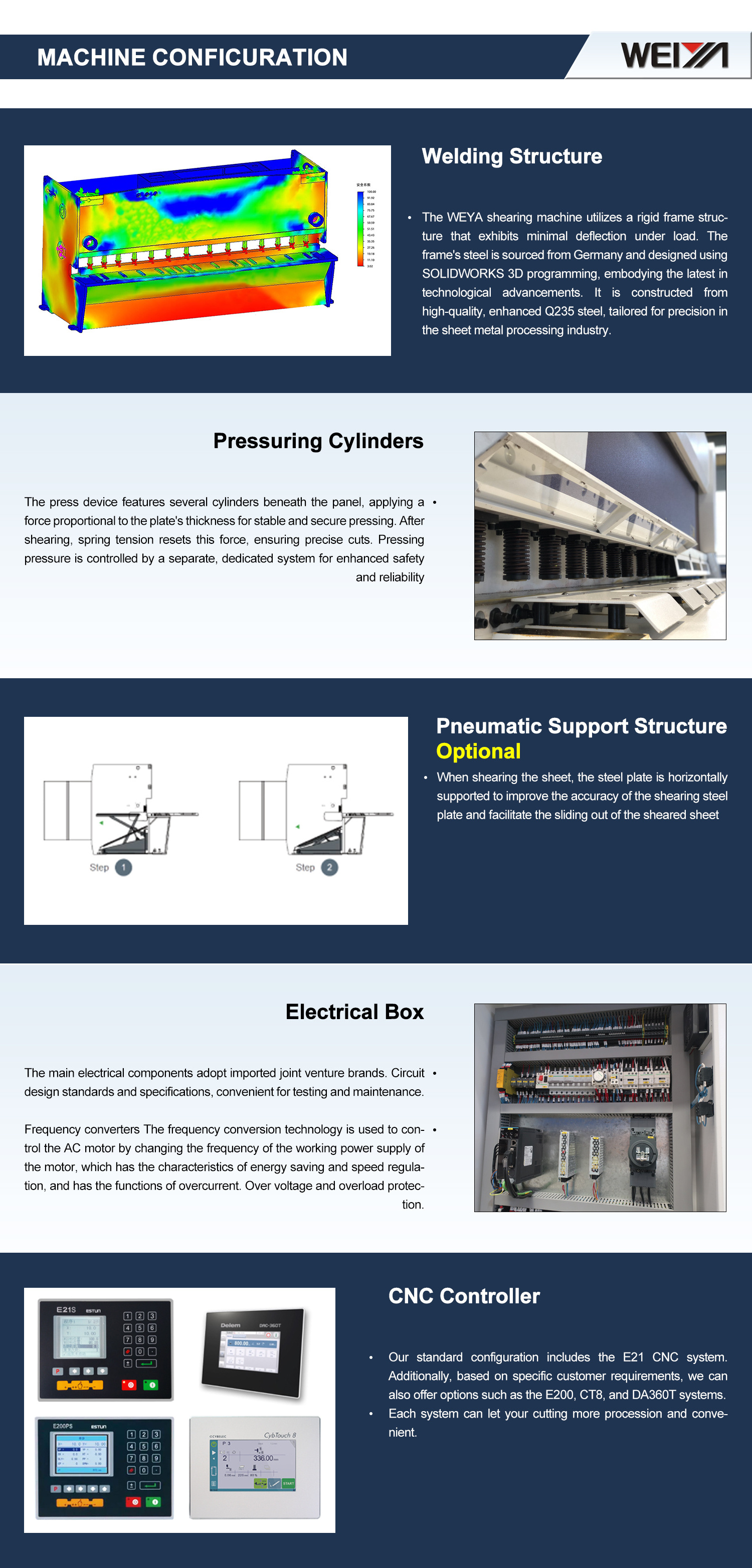

1. Constructed from all-steel welded structures, subjected to vibration aging treatment to eliminate internal stress, ensuring

both high rigidity and stability.

2. Features an integrated hydraulic transmission system, providing reliable performance.

3. Employs a triple support rolling guide rail system to remove support gaps and improve shearing precision.

4. Includes a mechanical rear stopper with manual fine-tuning and digital readout for precise adjustments.

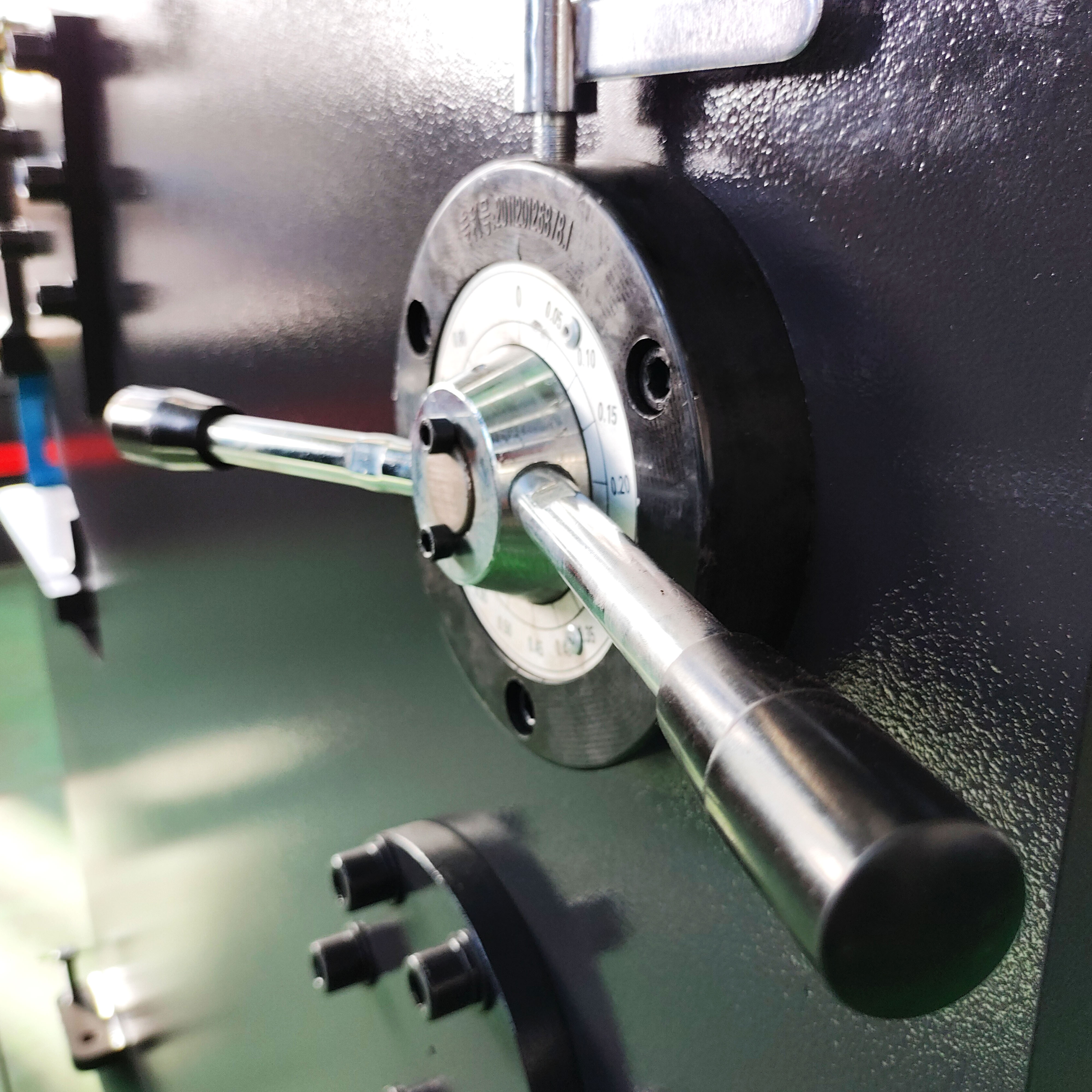

5. The gap between the shearing blades can be quickly and accurately adjusted via a hand wheel for convenience.

6. Uses rectangular blades with four cutting edges to extend service life, and the shearing angle can be adjusted to minimize

sheet deformation.

7. The upper blade holder is designed with an inward tilting mechanism to ease material feeding and enhance the accuracy of the

workpiece.

8. Equipped with a function for sectional shearing and alignment via a light indicator.

9. Optional: a rear material holding device is available for selection to suit different needs.

both high rigidity and stability.

2. Features an integrated hydraulic transmission system, providing reliable performance.

3. Employs a triple support rolling guide rail system to remove support gaps and improve shearing precision.

4. Includes a mechanical rear stopper with manual fine-tuning and digital readout for precise adjustments.

5. The gap between the shearing blades can be quickly and accurately adjusted via a hand wheel for convenience.

6. Uses rectangular blades with four cutting edges to extend service life, and the shearing angle can be adjusted to minimize

sheet deformation.

7. The upper blade holder is designed with an inward tilting mechanism to ease material feeding and enhance the accuracy of the

workpiece.

8. Equipped with a function for sectional shearing and alignment via a light indicator.

9. Optional: a rear material holding device is available for selection to suit different needs.

Hot Searches