- Product Details

- {{item.text}}

Quick Details

-

Power:

-

25kW

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

4500*2500*3500mm

-

Product name:

-

rice milling machinery

-

Application:

-

Rice Processing Machinery

-

Function:

-

Rice Milling Whitening Polishing

-

Advantage:

-

High Efficiency Working

-

Capacity:

-

1.5 ton per hour

-

Main combined machine:

-

Destoner, paddy husker, paddy separator, rice mill, rice grader

-

Feature:

-

High yield

-

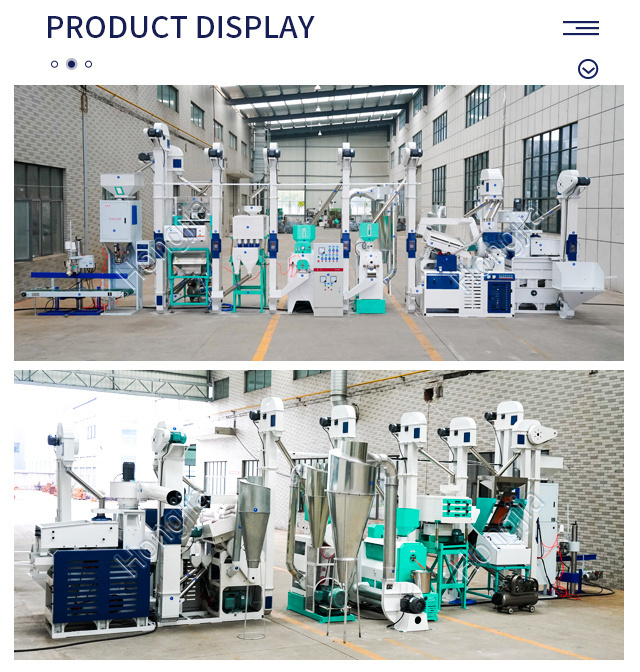

Type:

-

Modern design, fully automatic

-

Suit for:

-

White rice and parboiled rice

-

Color:

-

Green and white

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hongjia

-

Voltage:

-

380V

-

Power:

-

25kW

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

4500*2500*3500mm

-

Product name:

-

rice milling machinery

-

Application:

-

Rice Processing Machinery

-

Function:

-

Rice Milling Whitening Polishing

-

Advantage:

-

High Efficiency Working

-

Capacity:

-

1.5 ton per hour

-

Main combined machine:

-

Destoner, paddy husker, paddy separator, rice mill, rice grader

-

Feature:

-

High yield

-

Type:

-

Modern design, fully automatic

-

Suit for:

-

White rice and parboiled rice

-

Color:

-

Green and white

|

Specification

|

|

|

value

|

|||

|

Machine included

|

Power(kW)

|

|

Capacity output(kg/h)

|

|||

|

Showroom Location

|

Motor power(kW)

|

Total

|

1000-1500

|

|||

|

Single elevator(3m)

|

0.75

|

29.55kW

|

New

|

|||

|

Paddy cleaner&de-stoner

|

1.1

|

|

China

|

|||

|

Centrifugal fan

|

2.2

|

|

Henan

|

|||

|

Double elevator(3m)

|

0.75

|

|

Hongjia

|

|||

|

Rubber roller paddy husker(6 inch)

|

5.5

|

|

600kg/h, 700kg/h, 800kg/h, 900kg/h, 1000kg/h, 15 ton/day, 24 ton/day, 25 ton/day

|

|||

|

Paddy separator

|

0.75

|

|

380V

|

|||

|

Emery roller rice whitener

|

18.5

|

|

25kW

|

|||

|

Broken rice sieve

|

-

|

|

2000KG

|

|||

|

Installation size: 4500*2500*3500mm

|

|

|

4500*2500*3500mm

|

|||

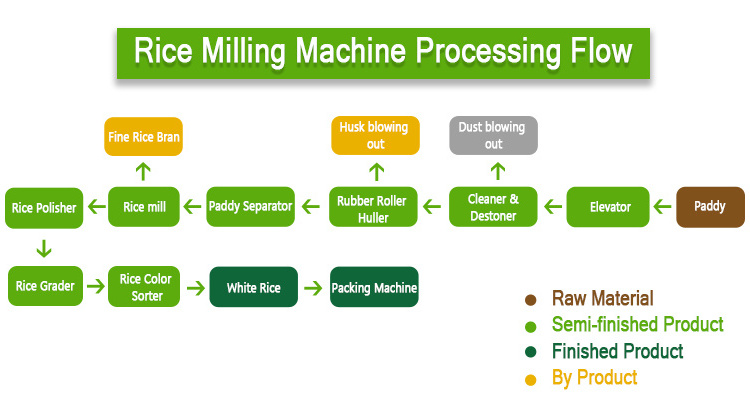

1. Patent ed modern design , combined rice mill , more durable than common machines

2. C ompact structure, easy operation,convenient maintenance, high yield

3. P rocessing rice in farmlands, towns, grain shops and households

4. S ome follow-up equipment can be added, such as polisher, color sorter, rice packaging machine, etc .

5. Better cleaning effect

6. B est choice for you to start a small scale rice milling factory

Pre-sale:

Plant selection: Supply professional design, layout drawing, process diagram, and equipment list.

Win-win cooperation: 1. Sign the contract 2. Establish mutual benefit, strategy.

In-sale:

Design evaluation: Design of process and equipment layout, electric power calculation.

Installation: 1. Quality and quantity guaranteed 2. Completion of handover Acceptance: Acceptance test

Technical training: 1. On-site installation and equipment training 2. Operation skills training 3. Maintenance training 4. Centralized technical training.

After-sale:

Technical service: Life-long technical service.

Master device: Free supply during the warranty period.

Accessories supplying: Supplying spare parts with cost.

Installation: oversea engineer service can be arranged at cost