- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Haikun

-

Color:

-

Gray Black

-

Shape:

-

Customized

-

Dimension:

-

Customized

-

Feature:

-

High hardness, high strength, high temperacture

-

Density:

-

>3.2g/cm³

-

Rockwell Hardness:

-

HRA90

-

Modulus of Elasticity:

-

290 Gpa

-

Compressive Strength:

-

2500 Mpa

-

Maximum Use Temperature:

-

1200℃

Quick Details

-

Material:

-

Silicon Nitride Ceramic

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

Si3N4-E063

-

Brand Name:

-

Haikun

-

Color:

-

Gray Black

-

Shape:

-

Customized

-

Dimension:

-

Customized

-

Feature:

-

High hardness, high strength, high temperacture

-

Density:

-

>3.2g/cm³

-

Rockwell Hardness:

-

HRA90

-

Modulus of Elasticity:

-

290 Gpa

-

Compressive Strength:

-

2500 Mpa

-

Maximum Use Temperature:

-

1200℃

Overview

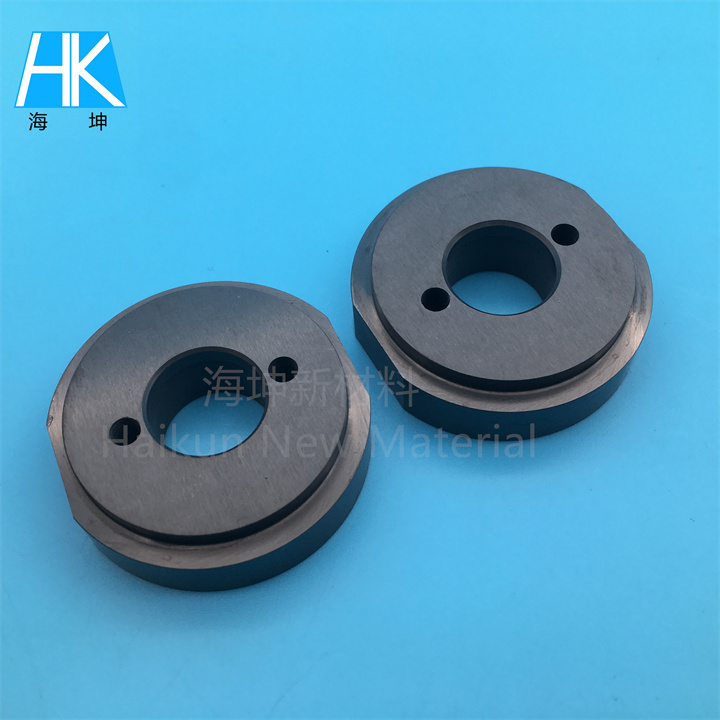

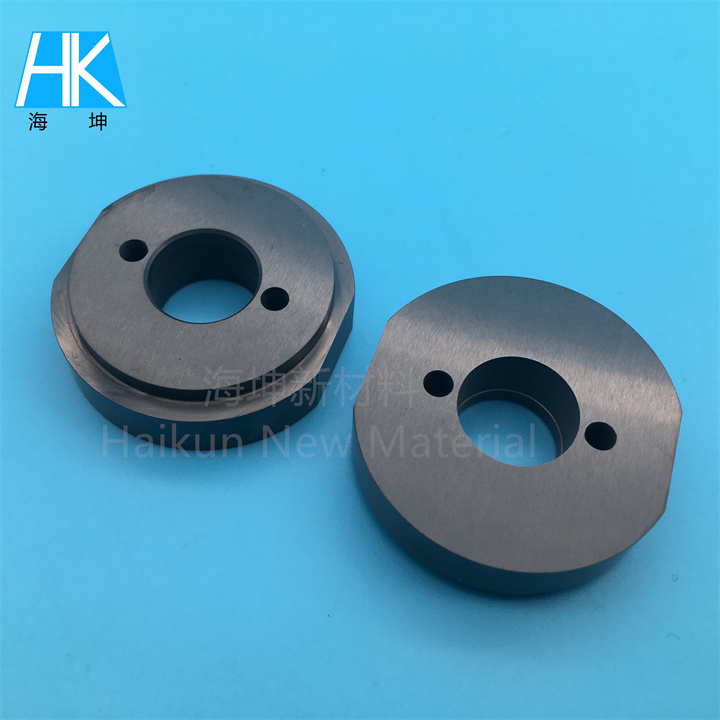

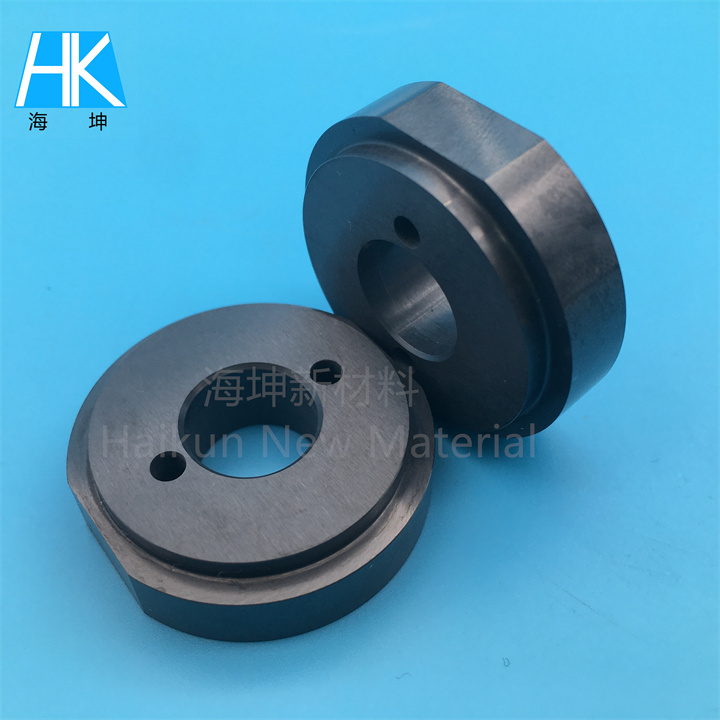

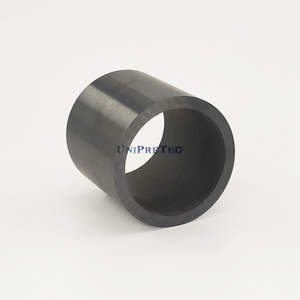

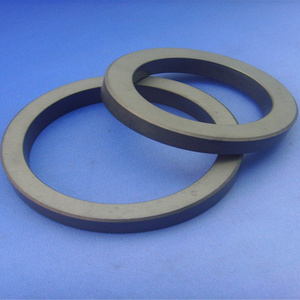

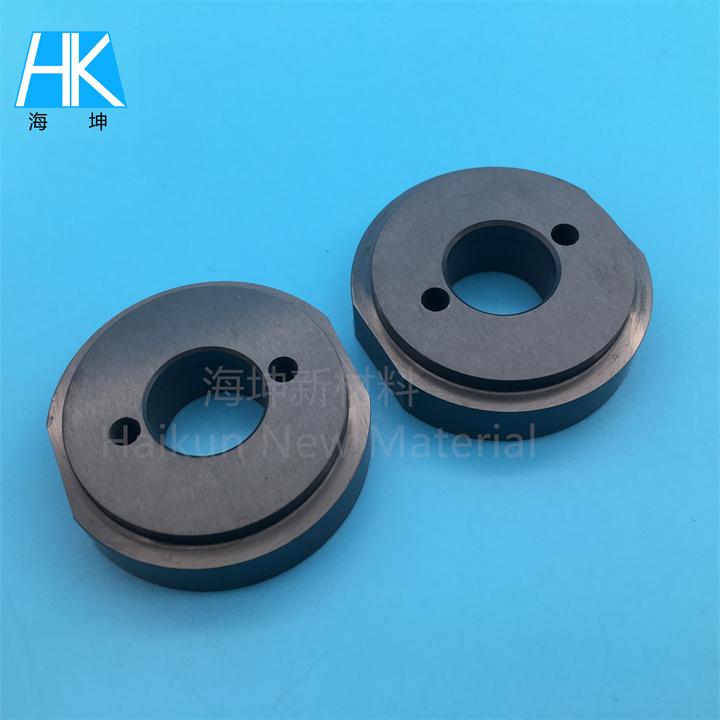

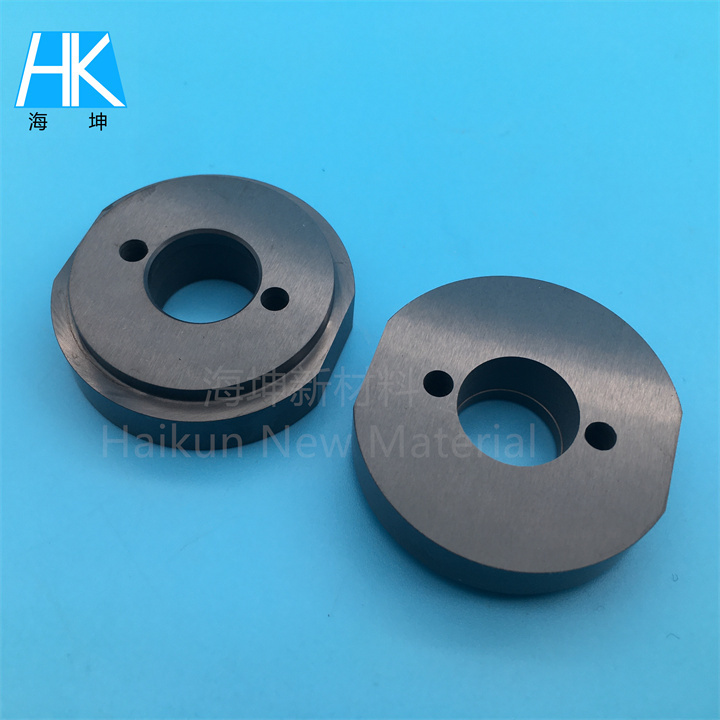

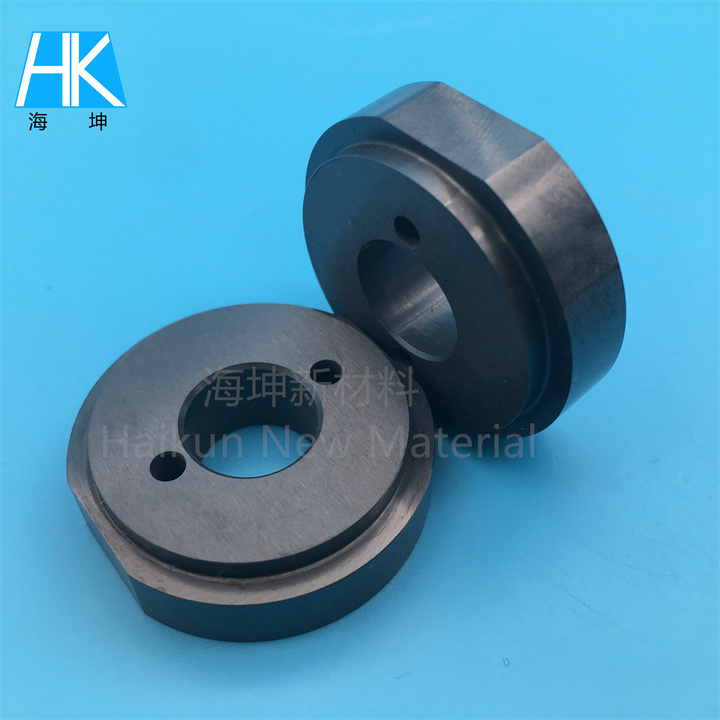

Silicon Nitride Ceramic Mechanical Seal and Shaft Sleeve Fine Ceramic Rings

Reputation depends on quality, quality comes from hard!

Product Description

Silicon Nitride Ceramic :

Silicon nitride exceeds other ceramic materials in thermal shock resistance. It also offers an excellent combination of low density, high strength, low thermal expansion and good corrosion resistance and fracture toughness.

silicon nitride has been used in a number of industrial applications, such as engine components, bearings and cutting tools.

Key Properties

* High strength over a wide temperature range

* High fracture toughness

* High hardness

* Outstanding wear resistance, both impingement and frictional modes

* Good thermal shock resistance

* Good chemical resistance

Typical Uses

* Rotating bearing balls and rollers

* Cutting tools

* Engine moving parts — valves, turbocharger rotors

* Engine wear parts — cam followers, tappet shims

* Turbine blades, vanes, buckets

* Metal tube forming rolls and dies

* Precision shafts and axles in high wear environments

* Weld positioners

Properties

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1200°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

|

|

||

|

Item |

Unit |

Typical Values |

|

Physical Properties |

||

|

Density |

g/cm3 |

>3.2 |

|

Mechanical Properties |

||

|

Rockwell Hardness |

|

HRA90 |

|

Vickers Hardness (Hv50) |

HV0.5 |

>1550 |

|

Modulus of Elasticity |

Gpa |

290 |

|

Flexural Strength |

Mpa |

>600 |

|

Compressive Strength |

Mpa |

2500 |

|

Fracture toughness |

Mpam1/2 |

>6.0 |

|

Thermal Properties |

||

|

Maximum use temperature |

°C |

1200 |

|

Thermal Conductivity |

W/(m.k) |

15-20 |

|

Thermal Expansion Coefficient |

10-6/°C |

>3.1 |

|

Thermal Shock Resistance |

T°C |

500 |

|

Specific Heat Capacity |

KJ/kg.K |

700 |

|

Electrical Properties |

||

|

Dielectric Strength |

KV/mm |

1 |

|

Dielectric Constant |

Er |

|

|

Volume Resistivity at 20°C |

Ω.cm |

1.0X1012 |

Application industry :

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application: Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.