We are a company specializing in the production of cooling towers, and our annual production capacity can reach more than 1,500 units.

Mainly engaged in OEM manufacturing in China, if you are satisfied with our products, want to use our products or want to become our dealer, you are welcome to place an order with us, and we will definitely give you the best product quality, service and experience.

We specialize in the production of square closed cooling tower and square open cooling tower. It include: counter flow cooling tower, cross flow cooling tower, and composite flow cooling tower.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

3.7~45

-

Place of Origin:

-

China

-

Brand Name:

-

Six Pagodas

-

Weight:

-

300 KG

-

Condenser/liner:

-

304 stainless steel

-

Cooling tower shell:

-

304 stainless steel

-

Water pump:

-

Brand motor

-

Price:

-

Cost-effective

-

Equipment:

-

Beautiful and novel

-

Cooling tower fan:

-

Brand motor

-

Spray pump:

-

Horizontal and 304 stainless steel impeller

-

Service life:

-

More than ten years

-

Water tank:

-

304 stainless steel thickened version

-

Control cabinet:

-

Brand electrical appliances can be customized with PLC

Quick Details

-

Cooling Type:

-

Counter Flow

-

Material:

-

Metal

-

Voltage:

-

Customized

-

Power:

-

3.7~45

-

Place of Origin:

-

China

-

Brand Name:

-

Six Pagodas

-

Weight:

-

300 KG

-

Condenser/liner:

-

304 stainless steel

-

Cooling tower shell:

-

304 stainless steel

-

Water pump:

-

Brand motor

-

Price:

-

Cost-effective

-

Equipment:

-

Beautiful and novel

-

Cooling tower fan:

-

Brand motor

-

Spray pump:

-

Horizontal and 304 stainless steel impeller

-

Service life:

-

More than ten years

-

Water tank:

-

304 stainless steel thickened version

-

Control cabinet:

-

Brand electrical appliances can be customized with PLC

Welcome to inquire about prices

Closed Cooling Tower

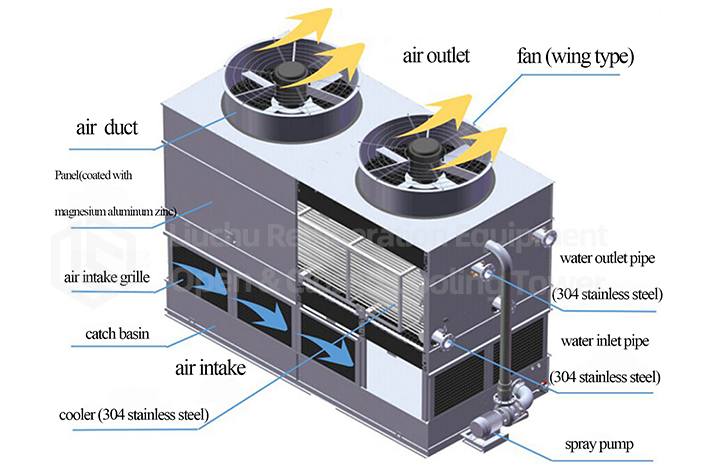

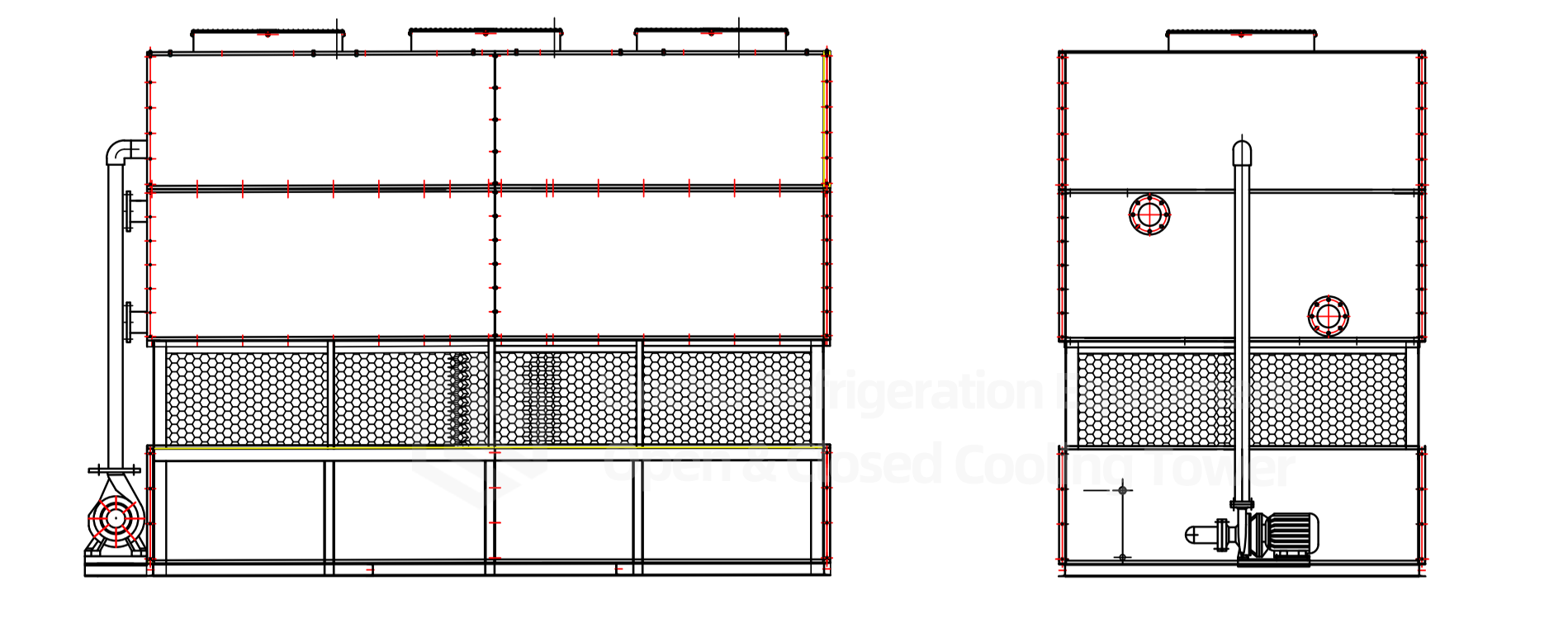

Cooling Tower Structure Diagram

Our cooling tower consists of a fan, water outlet pipe, water inlet pipe, spray pump, cooler, sump inlet grille, shell, air duct, etc. The water outlet pipe, water inlet pipe, and cooler are made of 304 stainless steel or 316 stainless steel. That is to say, the materials in contact with the circulating medium are all 304 stainless steel or 316 stainless steel. The material of the shell is magnesium-aluminum-zinc or 304 stainless steel.

Closed counterflow cooling tower

Open counterflow cooling tower

Working Principle Schematic Diagram

The circulating medium circulates in a closed pipeline, and the cooling effect is ensured through the heat exchange of the air spray water flowing through the outside and the heat dissipation of the fan.

Why Choose Us

our

Magnesium-aluminum-zinc plate is used to resist corrosion Pumps, fans, etc. adopt well-known brands

Life span is about ten years(except in harsh environments) Novel appearance and unique details After technical research, the cooling capacity is sufficient

other

Ordinary galvanized sheet

Poor quality of major accessories

After long use, other parts will rust

Overall appearance out dateddesign

Unstable cooling

Cooling Tower Details

Exquisite appearance, stable quality

Stainless steel shell protection

The water pump impeller is 304 stainless steel

Aluminum alloy blades, strong wind force, corrosion resistance

After the equipment is assembled, vacuum and anti-rust treatment is carried out. No iron filings are allowed before water testing

New M-type water collector effectively reduces water loss

Shockproof pressure gauge

SHINIJIA

First-line brand structural adhesive

Condenser 304 stainless steel coil

Water replenishment float valve 304 stainless steel

Microcomputer controls the set temperature and automatically starts and stops

The connecting pipes of the water pump are all made of 304 stainless steel.

Product Specification Customization

10—15T

20—40T

60—80T

100T

100-500T

304 stainless steel customized version

Water Tank Specifications

0.25

m³ water tank

0.5

m³ water tank

1

m³ water tank

4

m³ water tank

Applicable industries And Equipment

Air conditioning industry

Circulating water of compressor

Injection molding industry

Injection molding machine

Metallurgical industry

Smelting electric furnace

Electronics industry

Printing press

Chemical Industry

Air compressor

Foundry industry

Quenching water and oil

Quenching water and oil

Our Advantage

First-line brand water pump

Close to zero faults, only excellent quality can ensure stable production of equipment

304 stainless steel material

Everything in contact with the internal circulating water is 304 stainless steel

Stainless steel thickened water tank

Each water tank will undergo a water test before leaving the factory.

Microcomputer control

Through control, the fan and spray pump can start and stop automatically, which is more energy-saving.

Magnesium-plated aluminum-zinc plate

It is more corrosion-resistant and durable than ordinary plates. (304 stainless steel can be customized)

Technical installation guidance

Regarding installation and after-sales, we can provide you with technical support in the shortest possible time.

Some Customer Sites

Our Factory

Welcome to inquire about prices

Our advantage:

1. Using the highest quality materials and the most advanced production technology ensures that our cooling towers can provide excellent performance in a variety of environmental conditions.

2. Our cooling tower design takes into account factors such as energy saving and environmental protection, which can effectively reduce water and electricity consumption and reduce environmental impact. Customized cooling tower solutions can be provided to meet a variety of specific application needs.

3. We understand that each customer's needs are unique, so we provide customized cooling tower solutions to meet a variety of specific application needs.

4. We provide technical training services to help your team better understand and operate our cooling towers. Including product knowledge, operating skills, maintenance methods, etc., we will provide you with support as soon as possible.

5. If you need to replace any accessories, we can provide them for you in the shortest time. We have a large inventory of accessories and can quickly meet your needs.

FAQ

1. Question: What models and specifications do your cooling towers have? What is their cooling capacity?

Answer: Our company produces a wide range of cooling towers, from 6 tons-1000 tons (10RT-1650RT), which can meet various cooling needs.

2. Question: What material is your cooling tower made of? How durable are they?

Answer: The internal circulation of our cooling tower is made of 304 stainless steel, and the outer shell is made of magnesium-aluminum-zinc plate. These materials are well-known corrosion-resistant materials and can ensure the long-term stable operation of the cooling tower. In addition, you can also customize cooling towers made of all 304 stainless steel and 316 stainless steel to meet specific application needs.

3. Question: What kind of technical support is needed to install and maintain these cooling towers?

Answer: Our cooling towers are all installed and shipped. Customers only need to connect the inlet and outlet pipes at the customer site. No maintenance is required under normal operation, but antifreeze measures are required when the weather is cold.

4. Question: How to choose your cooling tower?

Answer: Provide the following information and we will customize a plan for you.

(1)Application: What cooling tower is used for cooling, such as extruders, injection molding machines, medium and high frequency furnaces, sintering furnaces, etc., and provides the basic parameters of the required cooling equipment.

(2)Water flow: How much water needs to be circulated per hour.

(3)Inlet and outlet temperature: the temperature of the water entering the cooling tower and the required temperature of the water leaving the cooling tower.

(4)Wet bulb temperature: Provided according to the region.

(5)Voltage and frequency: It can be customized according to the industrial power consumption in different places.

Hot Searches