- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

FMH

-

Color:

-

Black Etc

-

Material:

-

Synthetic Rubber

-

Reinforcement:

-

High Strength Synthetic Cord with helix wire

-

Feature:

-

Abrasion, UV, Aging,Corrosive Resistant

-

Application:

-

Industrial,marine and construction sites

-

Characteristics:

-

Easy Installtion And Less Maintenance

-

Working temperature:

-

-25℃ to +82℃

-

Certification:

-

ISO9001:2001

-

Safety factor:

-

5:1

-

Option:

-

Customized steel flanges are available

Quick Details

-

Processing Service:

-

Cutting

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Orientflex

-

Model Number:

-

FMH

-

Color:

-

Black Etc

-

Material:

-

Synthetic Rubber

-

Reinforcement:

-

High Strength Synthetic Cord with helix wire

-

Feature:

-

Abrasion, UV, Aging,Corrosive Resistant

-

Application:

-

Industrial,marine and construction sites

-

Characteristics:

-

Easy Installtion And Less Maintenance

-

Working temperature:

-

-25℃ to +82℃

-

Certification:

-

ISO9001:2001

-

Safety factor:

-

5:1

-

Option:

-

Customized steel flanges are available

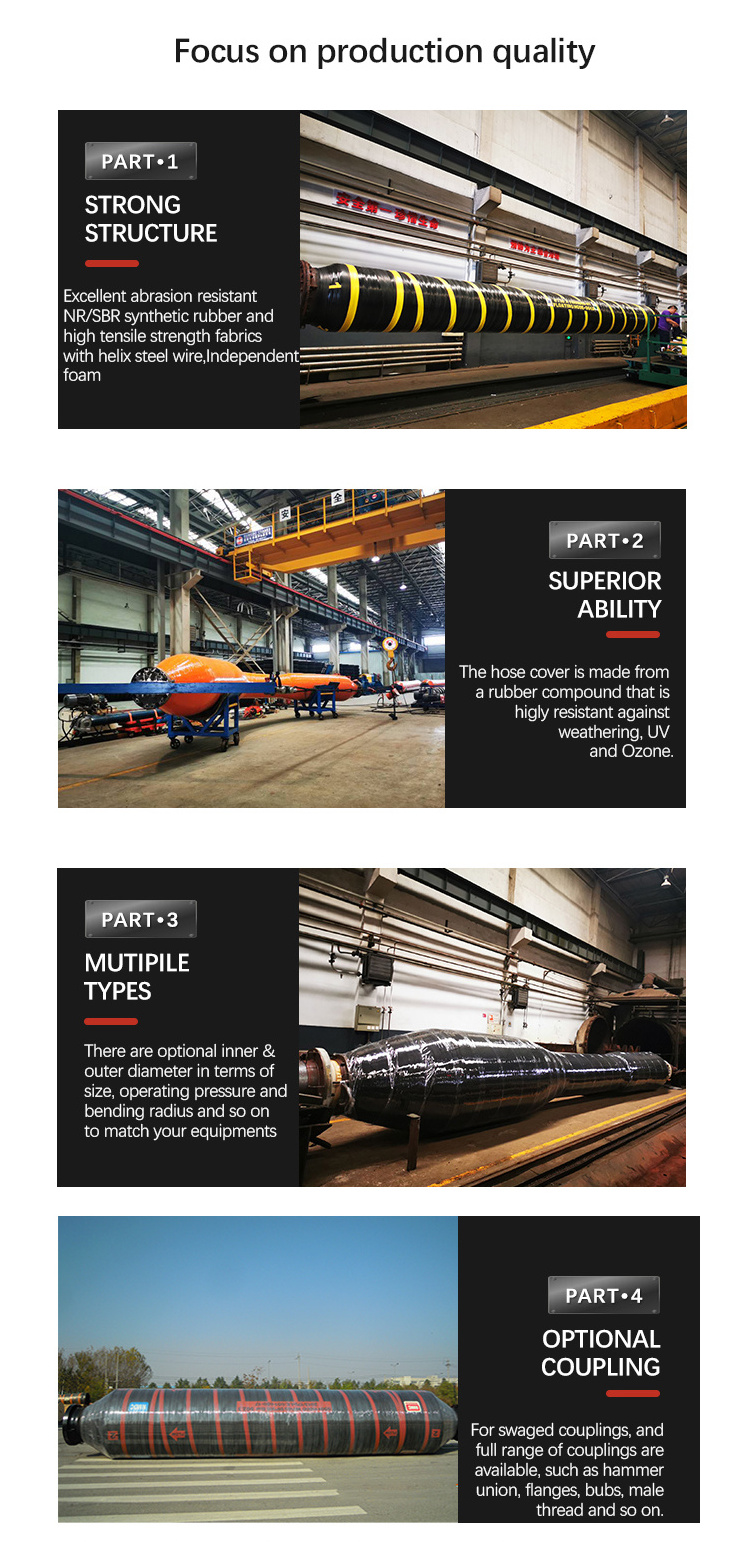

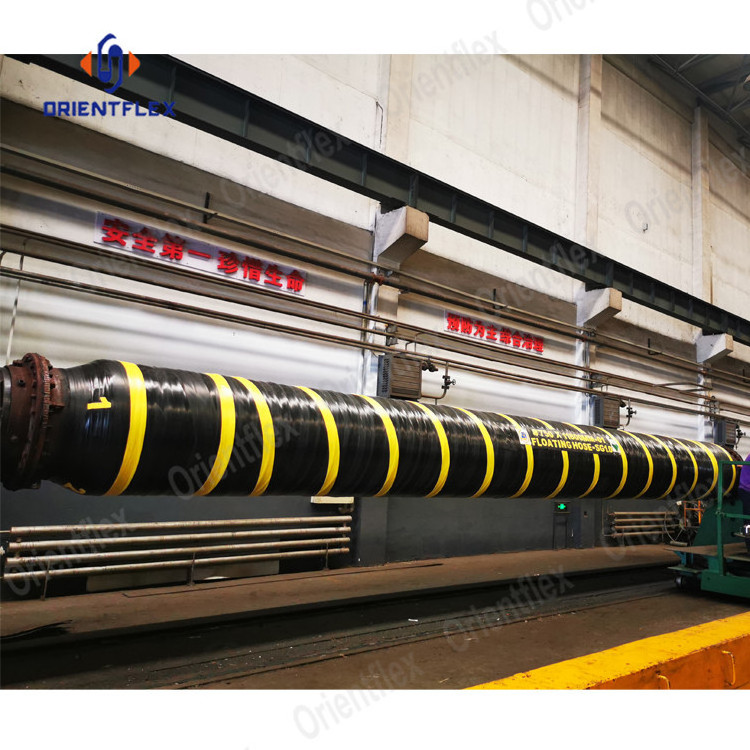

Construction:

Tube: Excellent abrasion resistant NR/SBR synthetic rubber.

Reinforcement: high tensile strength fabrics with helix steel

wire,Independent foam

Cover: CR synthetic rubber

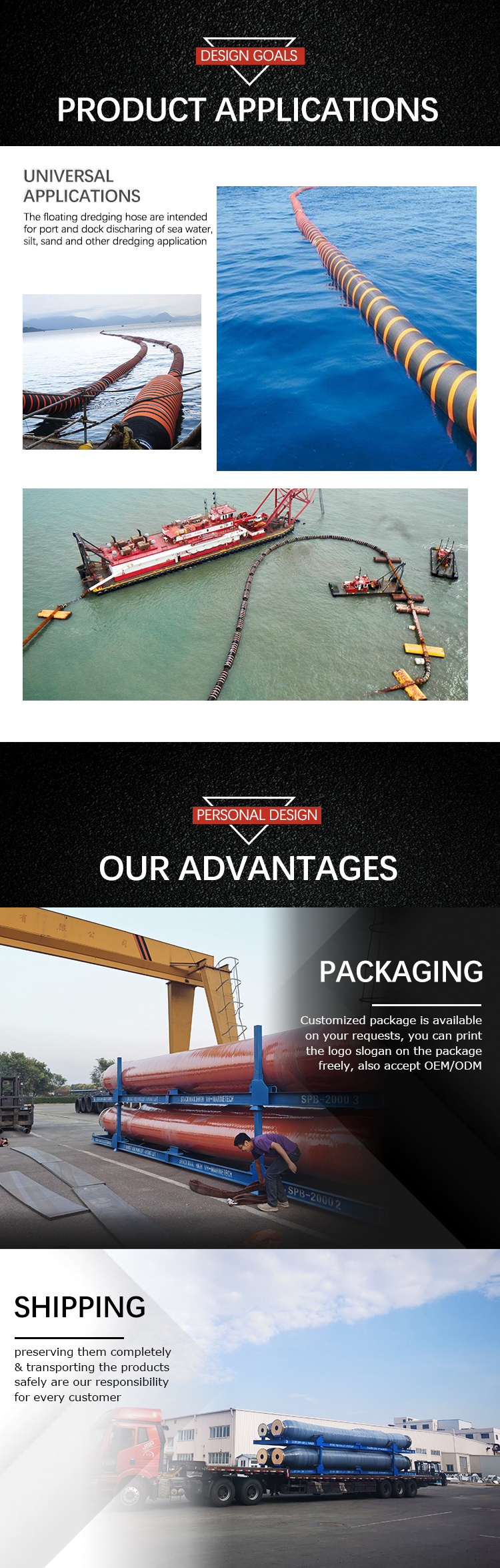

Application:

The floating dredging hose are intended for port and dock

discharing of sea water, silt, sand and other dredging

application. They are commonly used in part of the

construction process of docks and ports.

Characteristic:

The outer cover is made from a rubber compound that is

higly resistant against weathering, UV and Ozone.

Wear indicator layers can be implemented in the dredge

hoses which transport abrasive medium.

A single foam floating layer prevents water absorption. The

hose emergence above the water is not less than 20% of the

total volume.

Custom flanges are available.

Bending angle: in working conditions, the bending angle is

from 0°to +45°

| Item code | I.D. | W.P. | B.P. | Min Bending Radius |

Wear layer

Thickness |

Cover

Thickness |

Length | ||

| inch | mm | bar | bar | mm | mm | mm | m | ||

| FDH150 | 6 | 150 | 5-10 | 15-30 | 8D | 10-20 | 8-12 | 11.8 | |

| FDH200 | 8 | 200 | 5-10 | 15-30 | 8D | 10-20 | 8-12 | 11.8 | |

| FDH250 | 10 | 250 | 5-10 | 15-30 | 8D | 10-20 | 8-12 | 11.8 | |

| FDH300 | 12 | 300 | 10-20 | 30-60 | 12D | 12-25 | 10-15 | 11.8 | |

| FDH350 | 14 | 350 | 10-20 | 30-60 | 12D | 12-25 | 10-15 | 11.8 | |

| FDH400 | 16 | 400 | 10-20 | 30-60 | 12D | 12-25 | 10-15 | 11.8 | |

| FDH450 | 18 | 450 | 10-20 | 30-60 | 12D | 12-25 | 10-15 | 11.8 | |

| FDH500 | 20 | 500 | 10-20 | 30-60 | 12D | 12-25 | 10-15 | 11.8 | |

| FDH600 | 24 | 600 | 15-20 | 45-60 | 15D | 20-30 | 12-15 | 11.8 | |

| FDH650 | 26 | 650 | 15-20 | 45-60 | 15D | 20-30 | 12-15 | 11.8 | |

| FDH700 | 28 | 700 | 20-25 | 60-75 | 15D | 30-50 | 15-18 | 11.8 | |

| FDH750 | 30 | 750 | 20-25 | 60-75 | 15D | 30-50 | 15-18 | 11.8 | |

| FDH800 | 32 | 800 | 20-25 | 60-75 | 15D | 30-50 | 15-18 | 11.8 | |

| FDH850 | 34 | 850 | 20-25 | 60-75 | 15D | 30-50 | 15-18 | 11.8 | |

| FDH900 | 36 | 900 | 25-30 | 75-90 | 15D | 30-50 | 18-20 | 11.8 | |

| FDH1000 | 40 | 1000 | 25-30 | 75-90 | 15D | 50-75 | 18-20 | 11.8 | |

| FDH1100 | 44 | 1100 | 25-30 | 75-90 | 15D | 50-75 | 18-20 | 11.8 | |