- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

0

-

Productivity:

-

none

-

Weight (KG):

-

0 kg

-

Coating Thickness:

-

0.25-0.45mm

-

Elasticity:

-

500kn/mm

-

Adhesive:

-

3450n/Cm

-

Hardness:

-

6.0mohs

-

Standard Color:

-

Blue or Green

-

Double Sides Coating:

-

2-3 Coats Each Side

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ECOPRO

-

Material:

-

SUS304, Glass-Fused-to-Steel

-

Weight:

-

0

-

Productivity:

-

none

-

Weight (KG):

-

0 kg

-

Coating Thickness:

-

0.25-0.45mm

-

Elasticity:

-

500kn/mm

-

Adhesive:

-

3450n/Cm

-

Hardness:

-

6.0mohs

-

Standard Color:

-

Blue or Green

-

Double Sides Coating:

-

2-3 Coats Each Side

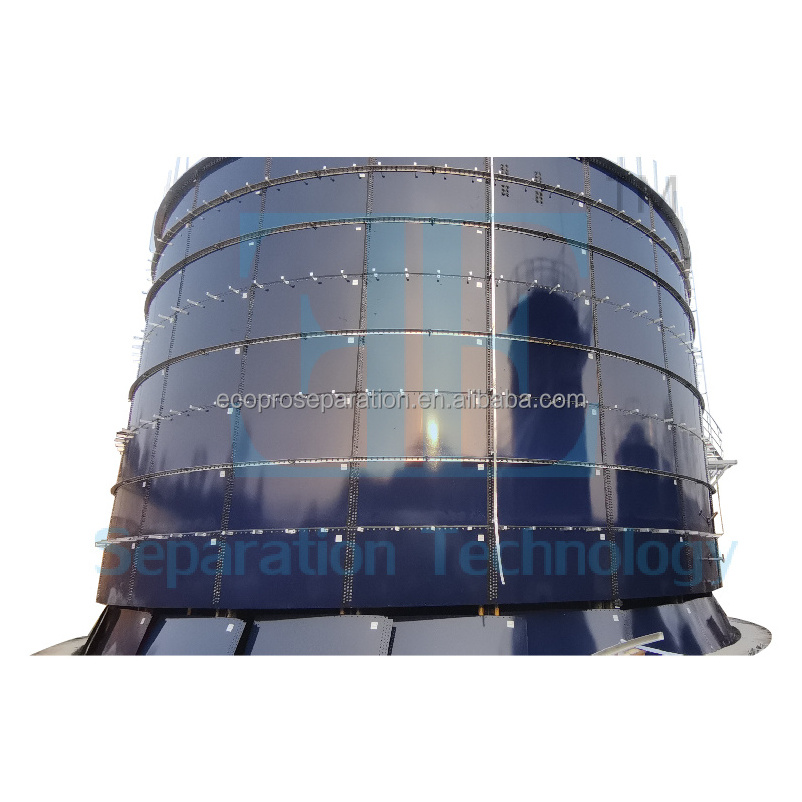

Enamel Assembled Tank Introduction

Enamel assembled tank was born in Europe and the United States in 20 th.

Global key suppliers: the CST in America, the Permastore in Britain, the Omerastor in Germany, the GLS in France and Holland, Denmark and other enterprises.

This excellent technology has be long in coming. At the beginning of this century, large biogas engineerning were imported from Germany and Czech.

It is widely recognized in biogas projects, which has become the mainstream technology of domestic biogas engineering.

Enamel assembled tank is used in factory production, double sided enamel firing on standard steel plate, assembled on site, seal in sealent, with fast installation, good corrosion resistance and other advantages, suitable for large containers such as water storage, oil storage and bulk storage, is a design life of up to 30 years to 50 years, acid and alkali resistant climate, the assembly is province labor, environmental protection recycling, is an environmentally friendly product.

Enamel assembled tank can be used to store storage of various types of wastewater, liquid and solid materials, especiallly as sewage treatment works, municipal engineering and industrial liquid storage container. It is an effective and practical method for storing or handling or transporting various fluids and solids. Assembled tank and storage tank has been in industrial and domestic sewage treatment plant gradually.

1. Sedimentation tank, regulating pool, desulfurizing pool and active carbon pool combined container;

2. SBR pool, contact oxidation tank, sedimentation tank, biological filter;

3. Silt collecting pool and its replacing pool, Leachate tank;

4. Seawater desalination, drilling mud;

5. Drinking water, process water, agricultural irrigation water;

6. Diesel oil, kerosene, aviation oil;

7. Power plant softening tank, desalting tank, ash silo.

Enamel Assembled Tank Production Line

Enamel Assembled Tank Features

*

Advanced enamel steel plate production technology and highly mechanized professional production line.

* Advanced coating technology, advanced firing process, environmentally friendly green production.

* Using the unique scale explosion prevention enamels closely combining with Q345 the high strength hot rolled steel plate.

* Provide necessary process and equipment design services.

* Provide efficient and safe installation construction services and improve after-sales service.

* Supply the highest cost-effective enamel assembled tank and biogas engineering products.

* Advanced coating technology, advanced firing process, environmentally friendly green production.

* Using the unique scale explosion prevention enamels closely combining with Q345 the high strength hot rolled steel plate.

* Provide necessary process and equipment design services.

* Provide efficient and safe installation construction services and improve after-sales service.

* Supply the highest cost-effective enamel assembled tank and biogas engineering products.

Enamel Assembled Tank Advantages

1. Shorter construction cycle and lower cost;

2. Beautiful appearance;

3. Excellent corrosion resistance;

4. Strong climate adaptability, adapt to any weather conditions;

5. Easy assembly and low site requirement.

2. Beautiful appearance;

3. Excellent corrosion resistance;

4. Strong climate adaptability, adapt to any weather conditions;

5. Easy assembly and low site requirement.

Installation Technology: the Current European Installation Method

Enamel Assembled Tank Worksite Photos

Partners in Worldwide

Hot Searches