- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

800x420x465mm

-

Weight (T):

-

0.04 T

-

Power (kW):

-

1.8

-

Certification:

-

CE S.G.S TUV ISO9001

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Chishun

-

Voltage:

-

110V/220V

-

Dimension(L*W*H):

-

800x420x465mm

-

Weight (T):

-

0.04 T

-

Power (kW):

-

1.8

-

Certification:

-

CE S.G.S TUV ISO9001

Product Overview

TF1200 Vacuum tube furnace

The TF1400 vacuum atmosphere tube furnace product is mainly designed for heat treatment of samples under vacuum or protective atmosphere. High quality furnace materials and stable temperature control system can ensure the reliability of experimental data; The product uses a new type of ceramic fiber material as the furnace material. The furnace tube material is excellent, and both ends of the furnace tube are sealed with stainless steel flanges, which can work under vacuum. The flanges have inlet and outlet ports, allowing for the passage of protective gas. The precision needle valve can adjust the intake flow rate.

FEATURES AT A GLANCE

Description

With 304 stainless steel sealing flange to obtain vacuum or atmosphere in the furnace tube

High-quality quartz glass working tube, and metal or corundum working tube can also be selected to adapt to different working conditions

The high-performance bipolar rotary vane vacuum pump can obtain a vacuum degree of 5pa, and the digital vacuum gauge can display the vacuum degree

With air circuit control unit, the control unit can choose 1-3 way MFC automatic control system

Product Paramenters

1. The furnace material is made of high-purity alumina ceramic fiber material, with a new assembly structure that does not deform at high temperatures and is sturdy and durable

2. The heating element adopts high-temperature alloy wire, which can withstand large loads, is stable, and has a long service life

3. The furnace tube is made of quartz tube, and the stainless steel flanges at both ends are designed to be simple, reasonable, and easy to disassemble, facilitating the entry and exit of sintered samples

4.The heating speed is fast, and it usually takes 15-30 minutes to rise from room temperature to 1000 degrees Celsius

5. Adopting intelligent PID temperature control instruments, with high temperature control accuracy and low impact temperature, with temperature compensation and correction functions, with an accuracy of ± 1 ℃

6. The temperature control instrument has a programming function, which can set the temperature rise curve and can be programmed for 30 segments

7. Integrated structure, excellent appearance and elegance

8. Electronic components are all well-known products with leakage protection function

9. This machine will issue an alarm signal for overheating during the working process and automatically complete the protection action

10. After the instrument program is set, as long as the run button is pressed, the next work will be automatically completed

11. Optional large screen paperless recorder for real-time recording of temperature rise curves, with storage card for analyzing and printing experimental data

12. Optional gas mass flow meter for precise digital control of incoming gas

PRODUCT SPECIFICATIONS

|

Model

|

TF1200-I

|

TF1200-II

|

TF1200-III

|

TF1200-IV

|

TF1200-V

|

TF1200-VI

|

|||||

|

Specifications

|

Φ25x600mm

|

Φ50x600mm

|

12L

|

18L

|

30L

|

45L

|

|||||

|

Furnace Size(mm)

|

150×150×150

|

200×300×120

|

200×300×200

|

250×300×250

|

300×500×200

|

300×500×300

|

|||||

|

Max Temperature

|

1200℃

|

|

|

|

|

|

|||||

|

Power Supply

|

220V/2.5KW

|

220V/3KW

|

220V/4KW

|

220V/5KW

|

380V/7.5KW

|

380V/12KW

|

|||||

|

Heating Element

|

High temperature alloy resistance wire

|

|

|

|

|

|

|||||

|

Furnace Material

|

Polycrystalline inorganic alumina ceramic fiber material prepared by wet vacuum filtration molding

|

|

|

|

|

|

|||||

|

Temperature Control Accuracy

|

±1℃

|

|

|

|

|

|

|||||

|

Temperature Control Instrument

|

Intelligent microcomputer PID temperature control instrument, SCR/SSR control, PID parameter self-tuning function; Programmable

for 30 time periods, including program heating, program insulation, and program cooling

|

|

|

|

|

|

|||||

|

Heating Rate

|

1-25℃/min free adjustment

|

|

|

|

|

|

|||||

|

Furnace Structure

|

Integrated structure of furnace temperature control

|

|

|

|

|

|

|||||

|

Sealing Performance

|

The furnace door flange is sealed, and high-temperature PTFE gaskets are installed on the furnace door; The furnace body is

equipped with an air extraction port, which can vacuum the furnace body with a vacuum degree of ≤ -0.098MPa (rotary vane vacuum

pump)

|

|

|

|

|

|

|||||

|

Atmosphere Performance

|

The inlet and outlet are designed on one side of the furnace body, allowing for the passage of inert protective gas

|

|

|

|

|

|

|||||

|

Equipment Protection

|

Modular control, which will emit sound and light alarm signals for overtemperature and disconnection during the working process,

and automatically complete the protection action

|

|

|

|

|

|

|||||

|

Safety Protection

|

There is an air circuit breaker installed on the equipment, which will automatically pop open in case of short circuit and

leakage, which can protect the equipment and operators

|

|

|

|

|

|

|||||

|

Shell

|

High quality cold rolled steel plate CNC machine tool cutting processing, after welding, grinding, polishing, phosphating,

pickling, surface electrostatic spraying plastic powder

|

|

|

|

|

|

|||||

|

Quality Certification

|

ISO9001 CE SGS TUV

|

|

|

|

|

|

|||||

|

Accessory

|

1. Furnace body、2. Temperature controller、3. Power cord 3 meters、4. Thermocouple、5. Instruction manual、6. Crucible pliers、7. High

temperature gloves

|

|

|

|

|

|

|||||

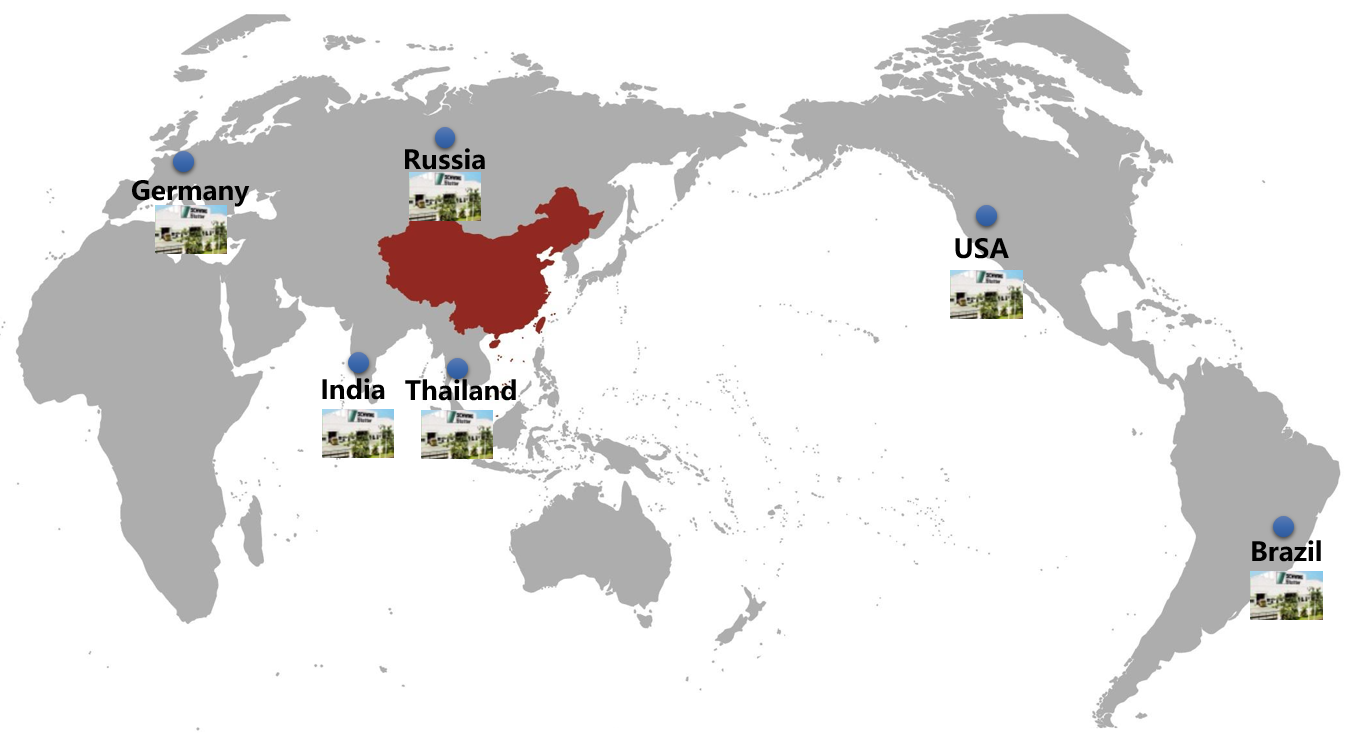

SALES AND SERVICE NETWORK

SIMILAR PRODUCTS

Hot Searches