- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LC-1510-G

-

other name:

-

aqueous gloss coating

-

product name:

-

water based varnish printing

-

purpose:

-

inks layer protection

-

main material:

-

acrylate resin

-

features:

-

both high wearing resistance and high gloss

-

Package:

-

a variety of option

-

usage:

-

paper or paperboard surface gloss coating

-

application:

-

in-line or off-line roller coating

-

drying method:

-

IR or hot air

-

state or appearance:

-

milky white liquid

Quick Details

-

Printing Type:

-

Offset printing

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LCCX

-

Model Number:

-

LC-1510-G

-

other name:

-

aqueous gloss coating

-

product name:

-

water based varnish printing

-

purpose:

-

inks layer protection

-

main material:

-

acrylate resin

-

features:

-

both high wearing resistance and high gloss

-

Package:

-

a variety of option

-

usage:

-

paper or paperboard surface gloss coating

-

application:

-

in-line or off-line roller coating

-

drying method:

-

IR or hot air

-

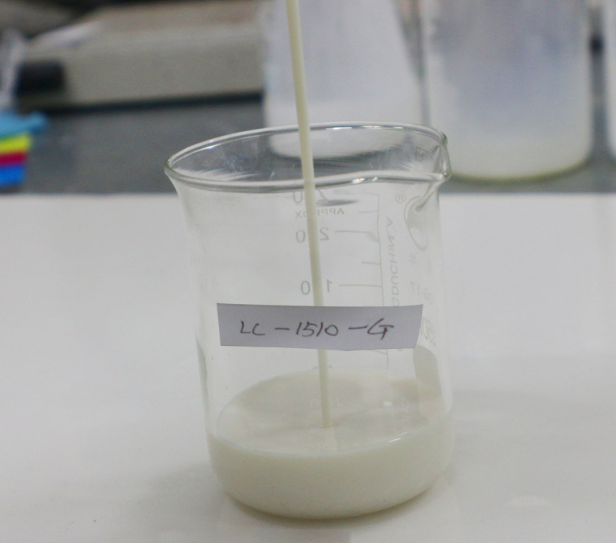

state or appearance:

-

milky white liquid

paper or paperboard surface coating inks protection water based varnish printing

water based varnish printing for paper or paperboard LC-1510-G

LC-1510-G is a modified acrylic polymer emulsion, is specially designed for paper printing glazing or coating requirements of products, through roller coating and after fully drying can improve the printing quality of the gloss, increase the printing products’ wear resistance, protect the imprinting and upgrade the additional value of printed matter. Have certain resistance to alkaline (NAOH), non-toxic, no smell, strong sense of transparency, no organic volatile emissions, without excitant odor, etc.

Product features:

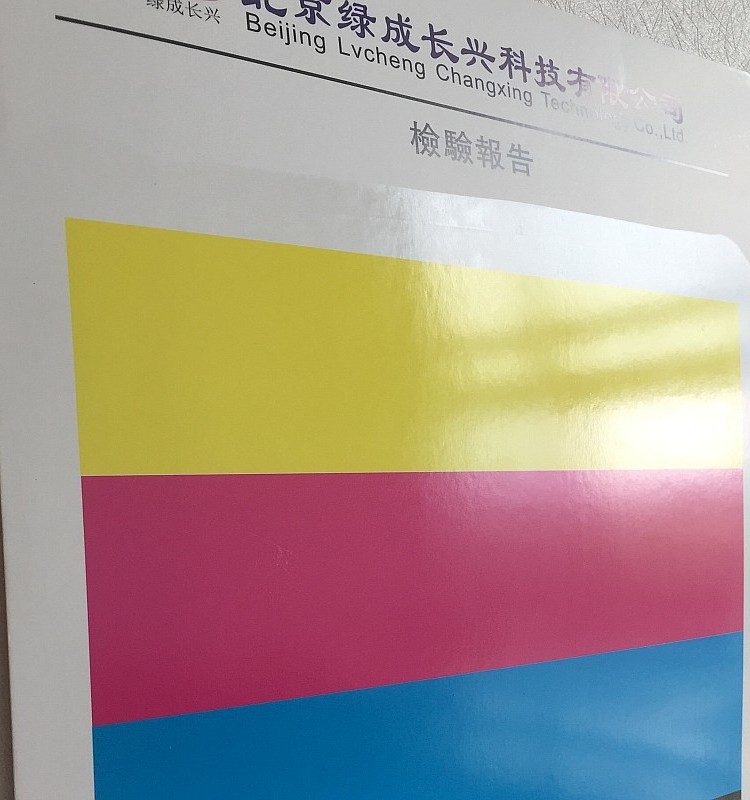

This product fit for both in-line printing machine with coating unit and off-line coating and glazing, have high wear resistance and high gloss degree, the original liquid’s rub resistance can reach at 1000 times, the gloss will be about 70°.

( Our customer test the waer resistance times )

common applied range :

Widely used for beer cartons, drinks cartons, electronic & electrical products package, color box etc., which these printed matter’s coating or varnishing need high wear resistance requirements, at the same time need high gloss.

|

General physical property ( varnish itself ) |

|

| Appearance(visual) | milk white opacity liquid |

| Solid content | 42±2%(( 150 ℃ ×30min,dry weight) |

| PH value | 7.6 ~ 8.6(PH meter) |

| Viscosity | Viscosity( T4# , 25 ℃) |

| Wearing resistance | 1000 times (4 pounds weight) |

| Gloss degree | 70 ±3 ° ( 60°angle ) |

range of application ( applied coating machine ):

1.Sheet fed offset printing, roller coating/glazing/varnishing element.(Cavity scraper or double-roller).

2.Drying method:IR or hot air.

3.In-line printing and coating.

Using/operating recommendation :

1.Dilution rate: if in-line printing and coating, use it directly; if off-line coating process, please according to the actual situation dilute reasonable with water, insure the product quality.

2.Please fully stir and test the viscosity before using.

3.Coating weight: when in-line 3~5 g/m²,when off-line 4~6 g/m², in order to insure the gloss and wear resistance property. After finishing coating, the varnish must dry well and guarantee the performance of anti-blocking.

4.Please use the printing inks which fit for varnishing or coating. When choose inks should consider the resistance against alkali, alcohol and solvents, in order to exclude and color change.

5.When using the non-absorptive base printing material or using slow-drying printing inks, suggested setting aside corresponding drying time.

6.Recommended paper-pile temperature: not exceeding 35℃.

7.Should have sufficient air flow between printed substrates, in order to insure rapid and complete drying, varnishing characters will be display fully after completel drying.

8.After finished the glazing, before the post processing, should test the printed substrates (paper-ink-varnish) whether they were complete drying and hardening. The printed substrates should be performed post processing when has a sufficiently & highly stability, thus reducing the influence of the mechanical tensile force and on the post processing.

9.If can’t use up one time after opening, please note seal preservation. Please clean the production equipment timely after using, don’t idle for a long time not to clean.

storage:

1.Keep from freezing, heating power and solar radiation.

2.Shelf time are 12 months from date of production.

3.Seal in the original container, suggested storage temperature environment is 5℃-30℃.

4.Keep from mixing with the other varnish or washing water.

5.If improper storage or the time is too long, maybe cause the viscosity raise and affect the using.

20KG/barrel,25KG/barrel,50KG/barrel,125KG/drum,1 ton/slot,also can meet special packing specification.