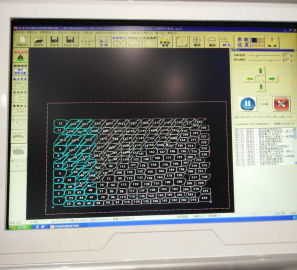

The controller system has been research and

developed by us, we own its copy right, it can accept 98% cloth CAD software and different file format PLT, DXF, CUT,TAC and so on.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YINENGTECH

-

Material Capabilities:

-

garment/cloth/textile/leather

-

Cutting thickness:

-

Max. 50m(vacuum suction)

-

Max cutting speed:

-

60m/min

-

Cutting accuracy:

-

≤±1mm

-

Cutting style:

-

Straight Knife Continuous Up-down Cutting

-

Software:

-

Automatic cutting system copyright

-

air pressure supply:

-

7 KPS

-

Motor and driver of pneumatic system:

-

SMC Japan

-

Application:

-

knitted and woven fabric, nowoven, pvc, shoes, leather, sofa

-

After Warranty Service:

-

Online support

Quick Details

-

Applicable Industries:

-

Clothing industry

-

Weight (KG):

-

4500

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

YINENGTECH

-

Material Capabilities:

-

garment/cloth/textile/leather

-

Cutting thickness:

-

Max. 50m(vacuum suction)

-

Max cutting speed:

-

60m/min

-

Cutting accuracy:

-

≤±1mm

-

Cutting style:

-

Straight Knife Continuous Up-down Cutting

-

Software:

-

Automatic cutting system copyright

-

air pressure supply:

-

7 KPS

-

Motor and driver of pneumatic system:

-

SMC Japan

-

Application:

-

knitted and woven fabric, nowoven, pvc, shoes, leather, sofa

-

After Warranty Service:

-

Online support

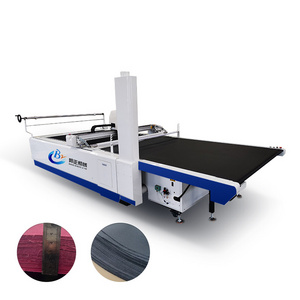

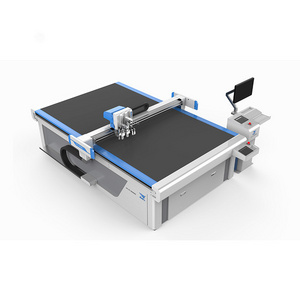

Product overview

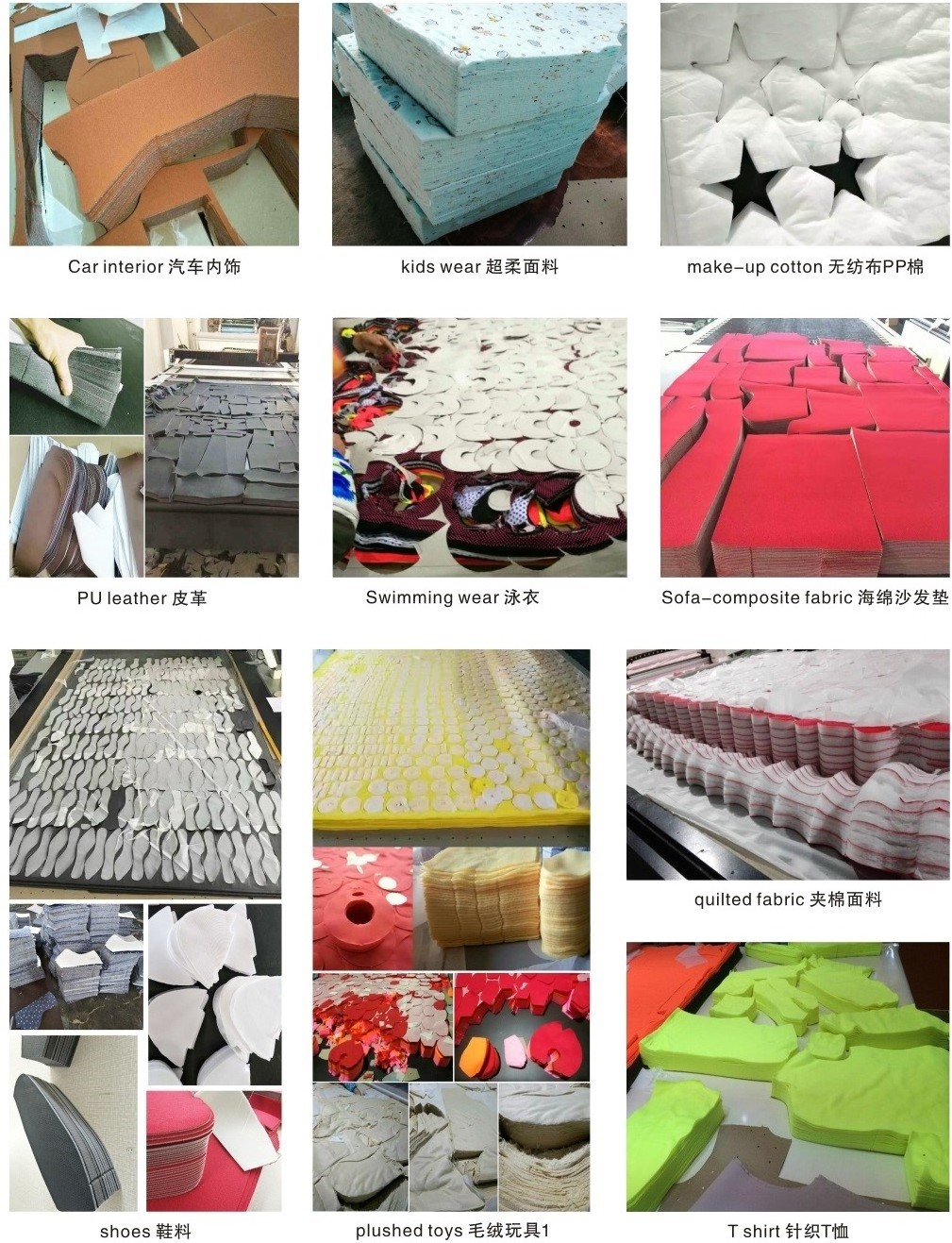

YINENG brand fabric Cutters are widely used for different markets: leisure fashion suits,children's garments,suits,knitting

casual/leisure suits, underwear ,swimsuit,corsage,seat cushion,massage chair,yacht/houseboat seat,shoes,cat,cold protective clothing,golf bag,handbag,home textiles,cow-bag,sleeping bag,tent, apparel,automotive, and furniture and soft fabric as well as other industries.

casual/leisure suits, underwear ,swimsuit,corsage,seat cushion,massage chair,yacht/houseboat seat,shoes,cat,cold protective clothing,golf bag,handbag,home textiles,cow-bag,sleeping bag,tent, apparel,automotive, and furniture and soft fabric as well as other industries.

Technical Paramenters

|

Model.NO

|

KP-X1725

|

KP-X2025

|

KP-X2325

|

KP-X1733

|

KP-X2033

|

KP-X2333

|

|||||

|

Cutting area (W*L)

|

1700x2500mm

|

2000x2500mm

|

2300x2500mm

|

1700x3300mm

|

2000x3300mm

|

2000x3300mm

|

|||||

|

Machine Dimensions (mm)

|

6000*2650*1500

|

6000*2950*1500

|

6000*3250*1500

|

7500*2650*1500

|

7500*2950*1500

|

7500*3250*1500

|

|||||

|

Weight

|

4200kgs

|

4500kgs

|

4800kgs

|

4800kgs

|

5000kgs

|

5500kgs

|

|||||

|

Max cutting thickness

|

70mm (After suction)

|

|

|

|

|

|

|||||

|

Max cutting speed

|

60m/min

|

|

|

|

|

|

|||||

|

Cutting accuracy

|

≤±1mm

|

|

|

|

|

|

|||||

|

Power

|

16-25kw

|

|

|

|

|

|

|||||

|

Cutting style

|

Straight Knife Continuous Up-down Cutting ( Vibrate alternately up and down to cut)

|

|

|

|

|

|

|||||

|

Cooling system

|

Auto air cooling system

|

|

|

|

|

|

|||||

|

Controller system

|

KP-ACS Copyright system which compatibility with any kind of cloth CAD software

|

|

|

|

|

|

|||||

|

Software

|

Multi-language ACS software, switch freely

|

|

|

|

|

|

|||||

|

sharpen way

|

double gear derogatory method

|

|

|

|

|

|

|||||

|

air pressure supply

|

0.55Mpa 160L/Min

|

|

|

|

|

|

|||||

|

Cutting materials

|

garment/cloth/textile/leather

|

|

|

|

|

|

|||||

|

Max speed of blade working

|

4000rpm/min

|

|

|

|

|

|

|||||

|

Motor & driver

|

Japan Panasonic servo motors & drivers

|

|

|

|

|

|

|||||

|

Machine power

|

AC380V/50HZ

|

|

|

|

|

|

|||||

|

Software

|

Auto cutting

|

|

|

|

|

|

|||||

Machine advantages:

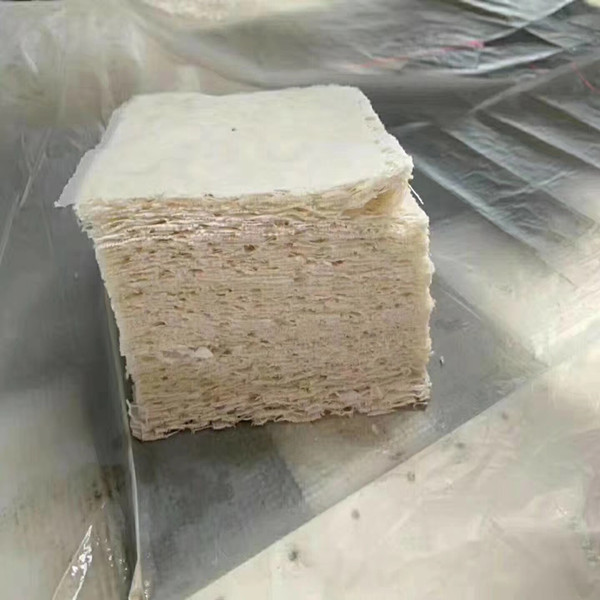

Create newest auto cutter is mainly designed for composite fabric, which adopts Euro-America design concept. Its max cutting thickness can reach 75mm after absorption and general cutting length is 2000mm.

1. Computer design , automatic typesetting, saving original materials.

2. Computer controlled and automatic cutting, save the human resource, mass production .

1. Computer design , automatic typesetting, saving original materials.

2. Computer controlled and automatic cutting, save the human resource, mass production .

3.Support many kinds of formats, direct open general dress design format, typesetting software .

4.The unique algorithm and motion control technology , realized seamless between straight line and arc.

5.High cutting accuracy, self -design of automatic sharp pen cutter, high quality of cutter makes life longer.

6.No need print out, save the typesetting, with high repeated utilization, plate-making management is convenient.

7.Easy to change the spare the spare part, and lower cost 8.Nice automation,easy to operate.

7.Easy to change the spare the spare part, and lower cost 8.Nice automation,easy to operate.

Customers cutting samples:

Products detials photos

Controller system:

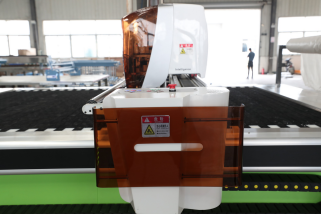

Safety system:

Safety device:Anti-collision device to prevent the machine hit someone who is standing by the machine.

XY transmission system:

The XY transmission system adopt the Germany gear and rack,the Mechanical precision error is less than 0.1mm,the gear and rack adopt the oblique gear and rack technic ,make the cutting much stable and precision,faster speed,long life,Smooth start-stop.

Machine body structures:

1.The machine body is whole body with full welding.

2.machine body is been milled by the Large five-axis milling machine with one time fine milling.

3.The machine body adopt the advance steel plate seamless connection of square box with high-speed machine bed structure.

2.machine body is been milled by the Large five-axis milling machine with one time fine milling.

3.The machine body adopt the advance steel plate seamless connection of square box with high-speed machine bed structure.

Knife sharpening system:

Adopts automatic knife sharpening technology.

Automatic senor system:

Automatic sensor system for secondary film cover: it can reduce the air leakage when

cutting.

cutting.

Exhibition

Product packaging

Buying Guide

Please contact us for more information. Your kind reply of following questions will help us to recommend the most suitable machine.

1, what material do you need to cut ?

2, What is the size and thickness of the material?

3, After processed, what will be the material used for? (application)

1, what material do you need to cut ?

2, What is the size and thickness of the material?

3, After processed, what will be the material used for? (application)

4, What cutting method is used in your factory , by machine or hand?

5, What about your current daily output , and your required daily output of the machine?

5, What about your current daily output , and your required daily output of the machine?

Hot Searches