- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

1

-

Voltage:

-

220/380v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Boshi multi lane packing machine

-

Dimension(L*W*H):

-

L1385*W918*H2005mm

-

Weight:

-

400 KG

-

Model:

-

BS-300BP

-

Film width:

-

Max.300mm

-

Film thickness:

-

0.03-0.1mm

-

Bag width:

-

20-70 mm

-

Bag length:

-

50-180 mm

-

Packing speed:

-

Each lane 20-40 bags/ min

-

Type of sealing:

-

Pillow bag ,3 /4 side seal bag,Special shaped bag

-

Packing material:

-

OPP/CPP, OPP/CE,PET/PE etc.

-

Air consumption:

-

0.8 mpa

-

Power:

-

50HZ/AC220V/380V/3.5kw

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Paper

-

Filling Material:

-

Powder, Other

-

Filling Accuracy:

-

1

-

Voltage:

-

220/380v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Boshi multi lane packing machine

-

Dimension(L*W*H):

-

L1385*W918*H2005mm

-

Weight:

-

400 KG

-

Model:

-

BS-300BP

-

Film width:

-

Max.300mm

-

Film thickness:

-

0.03-0.1mm

-

Bag width:

-

20-70 mm

-

Bag length:

-

50-180 mm

-

Packing speed:

-

Each lane 20-40 bags/ min

-

Type of sealing:

-

Pillow bag ,3 /4 side seal bag,Special shaped bag

-

Packing material:

-

OPP/CPP, OPP/CE,PET/PE etc.

-

Air consumption:

-

0.8 mpa

-

Power:

-

50HZ/AC220V/380V/3.5kw

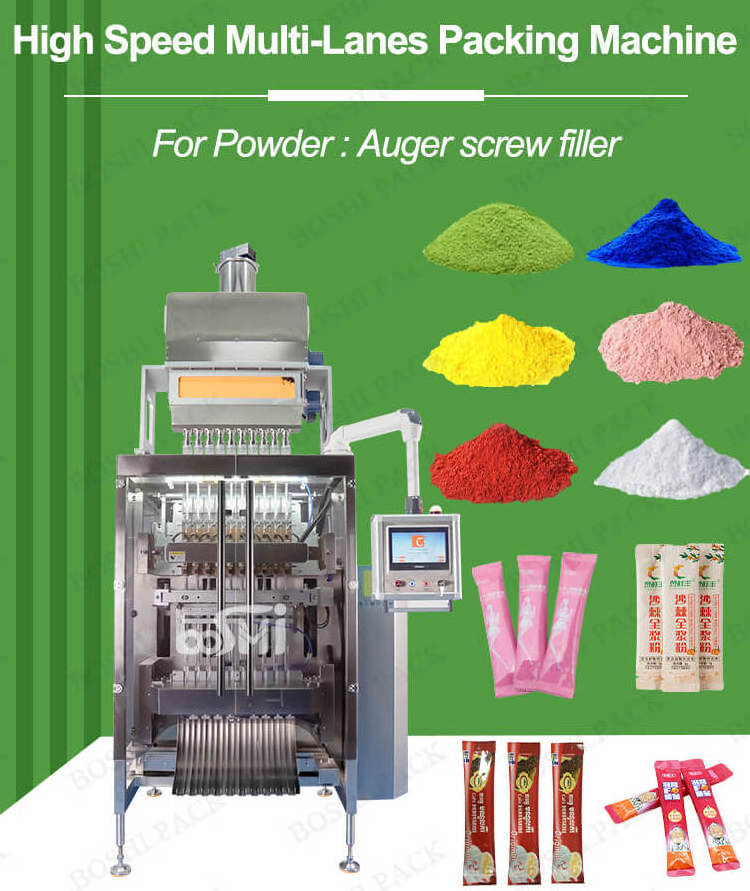

Machine Advantages :

1. PLC control with stable reliable biaxial high accuracy output and color touch screen, bag-making, measuring, filling,

printing,cutting , finished in one operation.

2. Separate circuit boxes for pneumatic control and power control. Noise is low, and the circuit is more stable.

3. Film-pulling with servo motor double belt: less pulling resistance, bag is formed in good shape with better appearance, belt is

resistant to be worn-out.

4. External film releasing mechanism: simpler and easier installation of packing film.

5. Adjustment of bag deviation just needed to be controlled by the touch screen. Operation is very simple .

6. Close down type mechanism , defending powder into inside of machine.

Bag Types

Technical Parameters

|

Model

|

BS-300BF

|

BS-600BF

|

BS-900BF

|

||

|

Number of Lanes

|

2-4 Lanes

|

3-10 Lanes

|

4-16 Lanes

|

||

|

packaging speed

|

20--40 cuts per minute/each lane

|

|

|

||

|

Bag size

|

L:50-180mm W:20-70mm

|

L::50-180mm W:20-95mm

|

Max.900mm,0.07--0.1mm

|

||

|

Film width film thickness

|

Max.300mm,0.07--0.1mm

|

Max.600mm,0.07--0.1mm

|

Max.900mm,0.07--0.1mm

|

||

|

Measurement method

|

1. Long screw; 2. Short screw; 3. Short screw + material rejection

|

30-80um

|

30-80um

|

||

|

Sealing bag type

|

Pillow bag, 3 side seal bag, 4 side seal bag, special shape bag

|

220V 50HZ,2.8KW

|

220V 50HZ,3KW

|

||

|

Incision form

|

1. Flat cutting; 2. wave cutting; 3. Rounded cutting; 4. Special-shaped cutting

|

Full servo motors

|

Full servo motors

|

||

|

Power supply

|

1N+PE/50HZ/AC220V/380V/3.5kw

|

1N+PE/50HZ/AC220V/380V/5.5kw

|

1N+PE/50HZ/AC220V/380V/7.5kw

|

||

|

Air consumption

|

0.8 MPA 0.8m3/min

|

0.8 MPA 0.8m3/min

|

0.8 MPA 0.8m3/min

|

||

|

Machine dimension

|

1385*918*2005mm

|

1685*1300*2005mm

|

1700*1600*2500mm

|

||

|

Machine weight

|

400kg

|

600kg

|

950kg

|

||

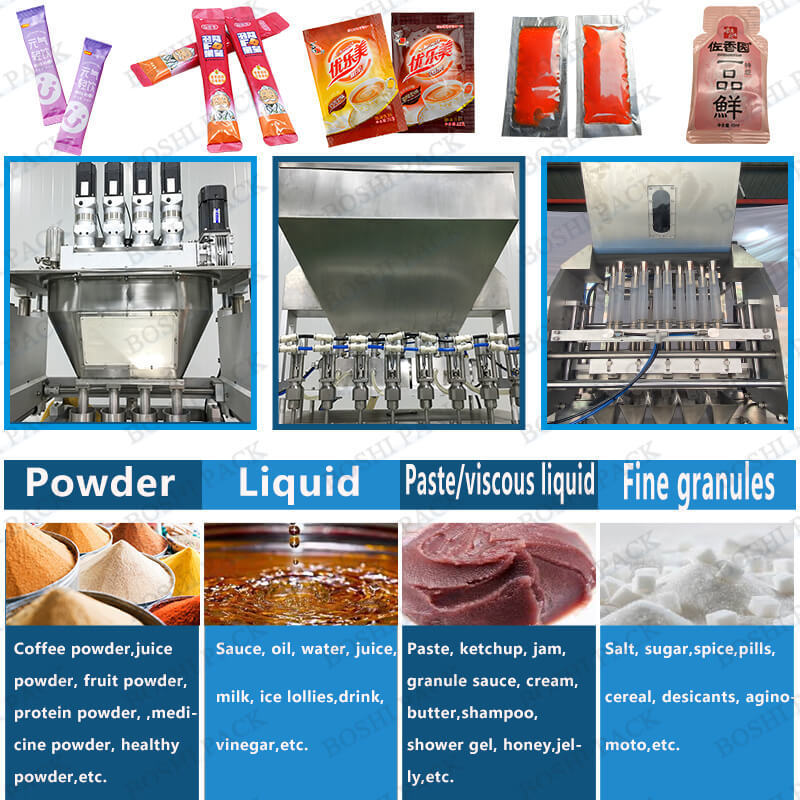

Applications

:

Suitable for filling and packing varieties of products:

This type of machine can make pillow bag and then finish the packing process. The main packager can be integrated with various filling systems, suitable for all kinds of products, such as powder, small granule, liquid, viscous liquid, paste,tablet, candy, solid, stick, large solid and irregular products

Main Features:

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

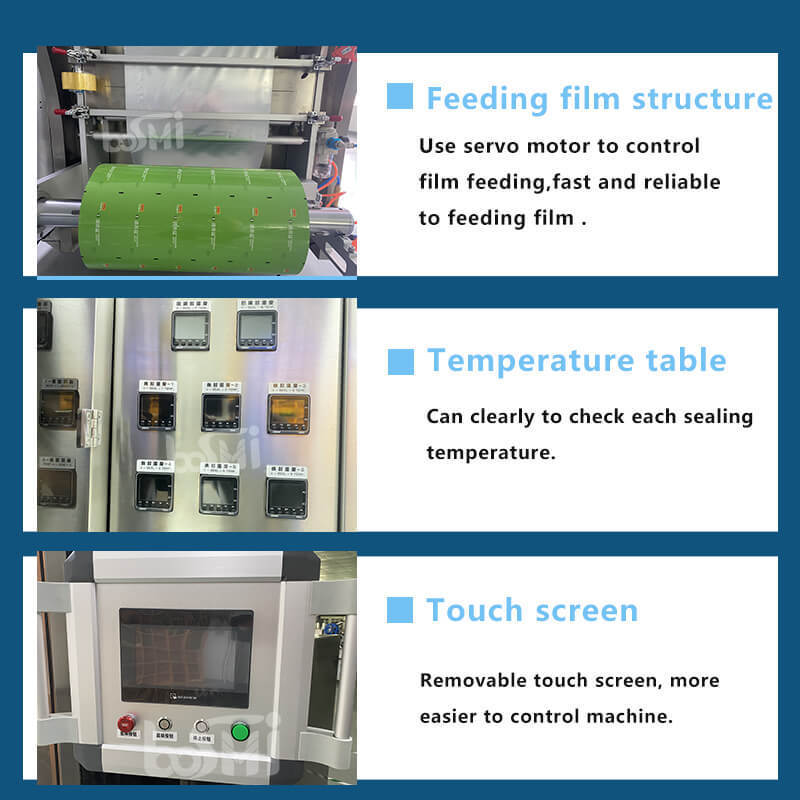

Machine Details

Forming bag structure

*We will according to your needed bag type to make different bag forming tubes.

*We will according to your needed bag type to make different bag forming tubes.

Touch screen

*Adjustment of bag deviation in the touch screen

*Adjustment of bag deviation in the touch screen

Temperature Table

*Monitor and adjust sealing temperature, also adjustable on the touch screen

*Monitor and adjust sealing temperature, also adjustable on the touch screen

Heat sealing structure

*Use stable heating sealing the bag, make bags firm and beauty.

*It suitable for many different film materials.

Feeding film structure

*Servo motor control the film feeding.The clamping film adopts the air-expansion shaft locking form, make it more convenient, fast and reliable for film replacement.

PLC & Electricity box

*Mitsubishi/ Siemens PLC control

*With stable reliable high accuracy output

*Panasonic servo motor driver pulling film

Material Hopper

* Materials will be fill in hopper

* Materials will be fill in hopper

*Hopper capacity can be customized

*With smart sensor to detected the material filling situation .

Multilane auger filler machine

* Each lane, with one set servo motor drive screw & stirring motor, stable and accurate .

* Each lane, with one set servo motor drive screw & stirring motor, stable and accurate .

End Seal Cutter Area

* Constant temperature heat sealing cutter is used to seal the front and rear ends of packaging products.

* Constant temperature heat sealing cutter is used to seal the front and rear ends of packaging products.

Packaging details:

1. Injection of powder to be packed

2. Transport plastic film

3. Print date

4. Bag making and powder filling

5.Complete packaging, cutting and conveying finished products

1. Injection of powder to be packed

2. Transport plastic film

3. Print date

4. Bag making and powder filling

5.Complete packaging, cutting and conveying finished products

CE CERTIFICATES:

About Us:

FOSHAN BOSHI PACKING MACHINERY CO., LTD.

Located in Foshan city, next to Guangzhou city, is a professional manufacturer of series

packing machine with morn than 13 years experience. Main produce packing machine as follows:

Multi-lanes packing machine

(For powder ,liquid ,granules product )

Pillow packing machine (For food, commodities, hardware , toys, soft, loose, solid products packing);

Granule packing machine (Multi-head weigher packing machine - For dry food, such as nuts, chips, candy .-For frozen food, such as dumpling, chicken leg, fish, pork. -For hardware screws. For vegetables,small fruits ,etc)

Line weigher /Volumetric cup packing machine ( For small granules like sugar, salt, rice,beans,nuts, grain )

Powder packing machine ( For coffee powder, milk powder, instant powder,flour, and etc.);

Liquid packing machine ( For sauce, jam, honey, juice, paste, jelly, oil, shampoo, and etc.);

Pillow packing machine (For food, commodities, hardware , toys, soft, loose, solid products packing);

Granule packing machine (Multi-head weigher packing machine - For dry food, such as nuts, chips, candy .-For frozen food, such as dumpling, chicken leg, fish, pork. -For hardware screws. For vegetables,small fruits ,etc)

Line weigher /Volumetric cup packing machine ( For small granules like sugar, salt, rice,beans,nuts, grain )

Powder packing machine ( For coffee powder, milk powder, instant powder,flour, and etc.);

Liquid packing machine ( For sauce, jam, honey, juice, paste, jelly, oil, shampoo, and etc.);

Extruder and packing machine

(For play dough, clay, flour dough, light dough, gel, energy bar ,etc.soft materials)

Cling film packing machine (For vegetable,fruit,meat, fish);

Shrink packing machine (For bottles, toys, books, plate, CDS, foods , commodities, and any other solid products)

Cling film packing machine (For vegetable,fruit,meat, fish);

Shrink packing machine (For bottles, toys, books, plate, CDS, foods , commodities, and any other solid products)

FAQ:

1.Why we choose you?

* Professional team 24 hours provide service for you

*13 months warranty,any main machine parts can be replacement

* Oversea service is provided

2.What is your payment term?

We support TT,Credit Card,Western Union,etc.

3.Are you manufacturer or trading company?

We are 100% real packing machine manufacturer.Any time online video will be supported.

4.You have engineer?can you design machine according my special product?

My boss is our biggest engineer with 15 years packing machine

experience.If needed,we can arrange online video with you and our engineer.That will be more efficient communication.

5.How to check your machine quality after machine finished?

Machine photos and test videos will be provided to before your balance. Also welcome you and third party to detect our machine.

6.How can I trust you will send machine to us after full payment?

We are a real factory with business license and certificate. Alibaba already let staff to inspect our factory.You pay via Alibaba trade assurance service,if we receive your payment,didn’t sent machine to you.Alibaba will off our online store and sent all your money back.

150g 300g 600g 1kg baking soda pea starch packing machine raising agent potato starch packing machine

150g 300g 600g 1kg baking soda pea starch packing machine raising agent potato starch packing machine

150g 300g 600g 1kg baking soda pea starch packing machine raising agent potato starch packing machine

150g 300g 600g 1kg baking soda pea starch packing machine raising agent potato starch packing machine

Hot Searches