- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

SMT660

-

Number of feeders:

-

64

-

Applicable Components:

-

0402, 0603, 0805, 1206, diode,triode, BGA SOT, etc

-

MAX circuit board area:

-

600*455mm

-

Tape feeder:

-

8, 12, 16, 24mm and vibration suction

-

Software:

-

English

-

Drive motor:

-

Panasonic Servo Motor

-

MIN/MAX:

-

0201/40*40mm

-

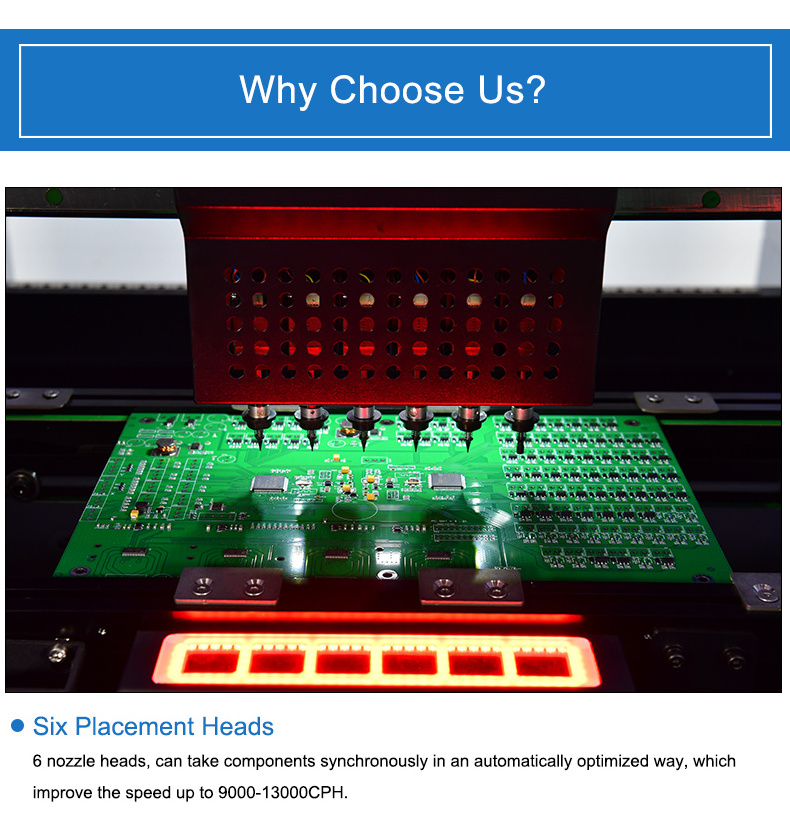

Placement Head Quantity:

-

6

-

After Warranty Service:

-

Video technical support

Quick Details

-

Weight (KG):

-

498

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YX

-

Model Number:

-

SMT660

-

Number of feeders:

-

64

-

Applicable Components:

-

0402, 0603, 0805, 1206, diode,triode, BGA SOT, etc

-

MAX circuit board area:

-

600*455mm

-

Tape feeder:

-

8, 12, 16, 24mm and vibration suction

-

Software:

-

English

-

Drive motor:

-

Panasonic Servo Motor

-

MIN/MAX:

-

0201/40*40mm

-

Placement Head Quantity:

-

6

-

After Warranty Service:

-

Video technical support

Product Description

SMT660 Intrduction

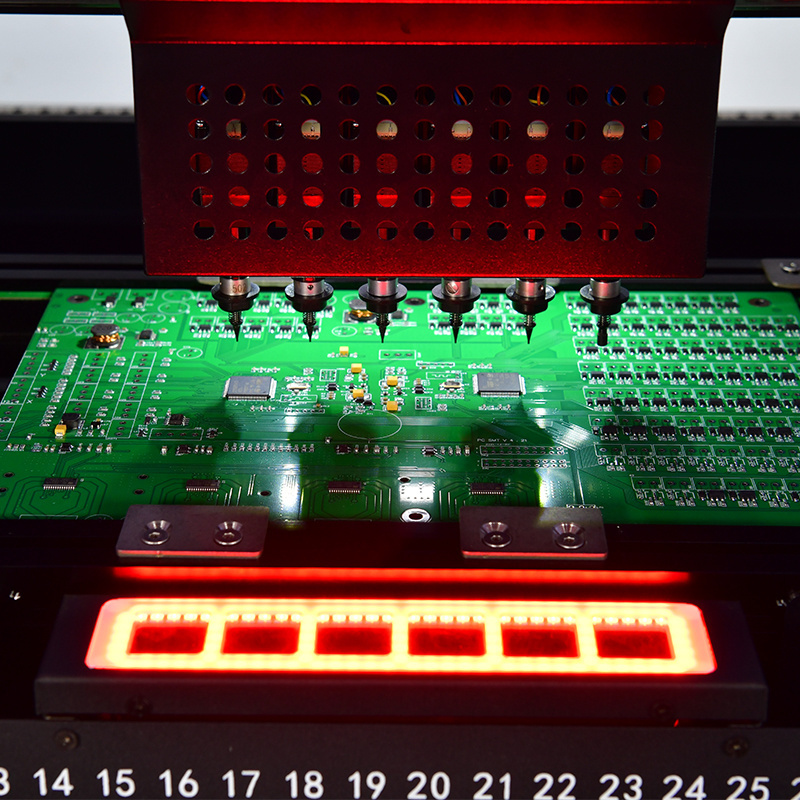

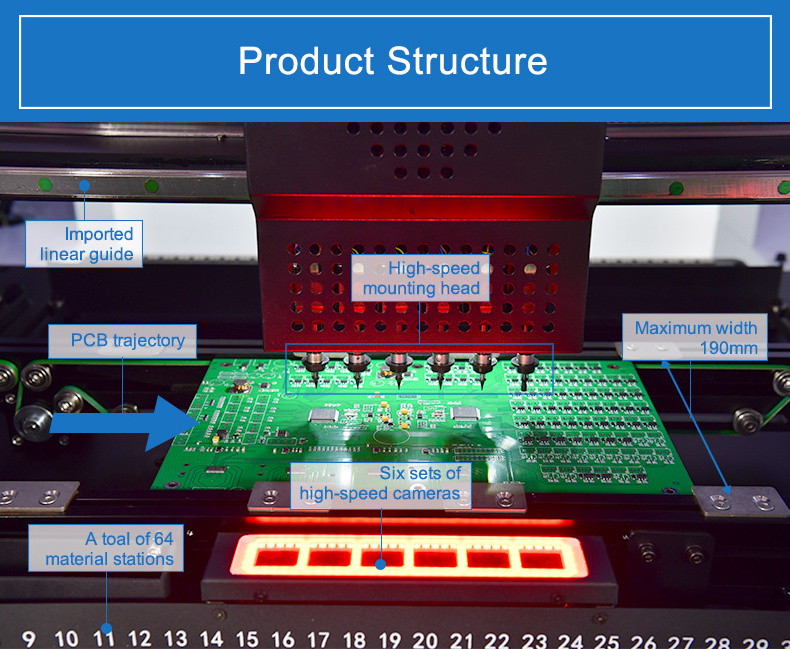

The machine SMT660 with 6 heads+8 camera+Conveyor+64 feeders+Panasonic servo motor+Straight guide rail+Screw Guide .

SMT660 Feature

1.Panasonic servo motor. 2.Straight guide rail.

3.Screw Guide.

4.6 Heads+8 cameras+64 feeders.

SMT660 Packing List

1.Pick and place machine:1 Set 2.IC fixed support:4 Set(four M5*8,four M5*16)

3.JUKI nozzle:16 Pcs(502*4,503*4,504*4,505*3,506*1)

4.Calibration suction nozzle:4 Pcs

5.Power wire:1 Pcs

6.Fixed foot:4 Pcs(Diameter 20mm)

7.The keyboard and mouse:1 Set

8.Nozzle calibration inkpad:1 Box

9.Lubricant:1 Pcs

10.Chassis key:1 Pcs

11.PC:1 Set

12.17 inch liquid crystal display:1 Set

The SMT660 software was developed by ourselves.

The software is available in English. And our software will be updated, as soon as there is an update, the salesman will send new software to your mailbox.

The SMT660 machine has one year warranty, lifetime maintenance.

We have a professional after-sales team. As long as there is a problem with the machine within one year after purchase, we will repair it for free. If there is a need to replace the accessories, we will send them to your hands for free.(Generally we use TNT/DHL. 3-5 business days to your hands)

|

Number of feeders

|

64

|

|

Number of head

|

6

|

|

Number of camera

|

8

|

|

Number of IC Tray

|

6

|

|

Average power

|

500W

|

|

Positioning precision

|

0.01mm

|

|

The buffer range of suction nozzle

|

4.5mm

|

|

Power supply

|

220V, 50/60Hz

|

|

Compressed air

|

0.5-0.6Mpa

|

|

Drive motor

|

Panasonic servo motor

|

|

Vacuum source of suction nozzle

|

high-speed on-off vacuum generator with vacuum breaker

|

|

Maximum circuit board area

|

600×455mm

|

|

Maximum travel scope in Z axis

|

20mm

|

|

Tape feeder

|

8, 12, 16, 24mm and vibration suction (mounting pipe chip)

|

|

Maximum mounting speed

|

12000 Pcs/h

|

|

Average mounting speed of actual mounting resistance

|

9600Pcs/h

|

|

XYZ drive guide rail

|

TBI high-precision reloading linear guide rail

|

|

Motion drive system

|

Panasonic high-speed DSP drive

|

|

Operating system

|

full-automatic chip mounter operating system independently

|

|

|

developed by Huawei Guochuang based on Windows

|

|

|

operating systemand it supports windows xp

|

|

|

win7 operating system

|

|

Element angle

|

0-360°, synchronous rotation during movement

|

|

X/Y operation mode

|

intelligent curve of the linear acceleration and deceleration linkage

|

|

MARK point positioning

|

full-automatic (the MARK point can be adjust at will)

|

|

Intelligent alarm

|

automatic correction, automatic filling, feeding shortage alarm

|

|

Plate entering mode

|

automatic connection from left to right in single sections,

|

|

|

automatic PCB transfer positioning. /plunger positioning,

|

|

|

manual plate feeding.

|

|

Visual display

|

17-inch industrial control display, 4:3, resolution: 1280 x1024

|

|

|

One Mark recognition camera, four quick-recognition cameras

|

|

|

and one precise-recognition camera

|

|

Adaptive mounting scope

|

Adaptive to 0201, 0402, 0603, 0805, 1206, diode, audion, SOT, QFP

|

|

|

within 40*40mm and the pin distance ≥0.3mm

|

|

|

(0.5mm center distance) and BGA

|

|

Product weight

|

500KG

|

|

Dimension

|

1450*1370*1550mm

|

Product Details

Hot Searches