- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hongya

-

Model Number:

-

glass blowing pipes

-

Size:

-

OEM, Customized

-

Thickness:

-

OEM, 0.1mm-10mm

-

Color:

-

red, opaque black, opaque white, pink,purple, green,yellow, amber,etc

-

Feature:

-

high heat resisance

-

Material:

-

Borosilicate COE3.3 Glass

-

Usage:

-

light, smoking pipe, labw

Quick Details

-

Type:

-

Tempered Glass

-

Application:

-

Lighting Glass

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hongya

-

Model Number:

-

glass blowing pipes

-

Size:

-

OEM, Customized

-

Thickness:

-

OEM, 0.1mm-10mm

-

Color:

-

red, opaque black, opaque white, pink,purple, green,yellow, amber,etc

-

Feature:

-

high heat resisance

-

Material:

-

Borosilicate COE3.3 Glass

-

Usage:

-

light, smoking pipe, labw

Product Description

Specifications

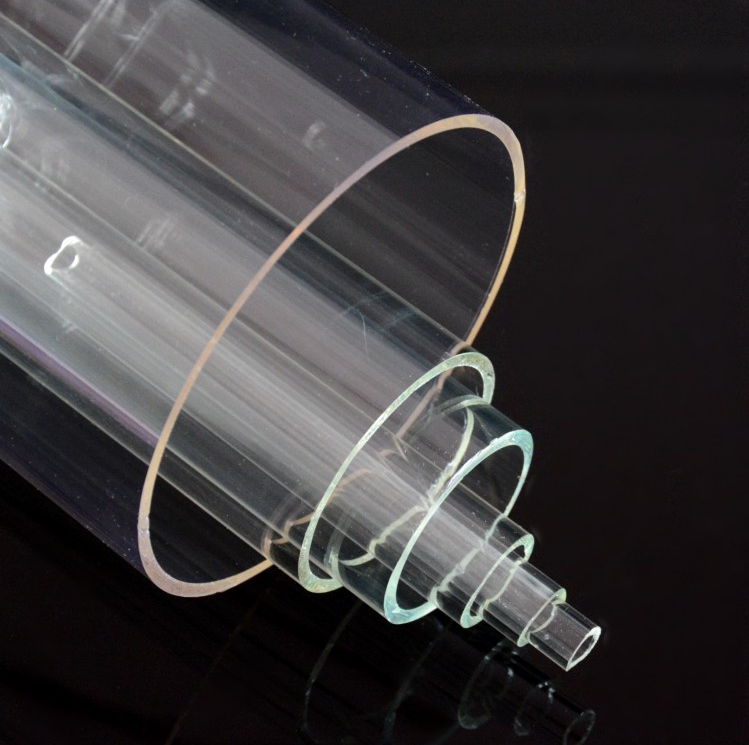

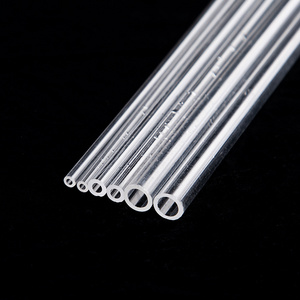

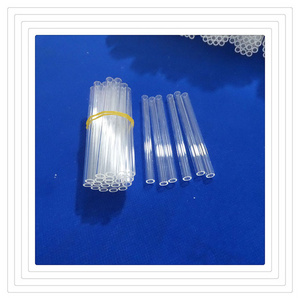

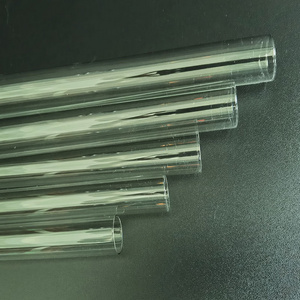

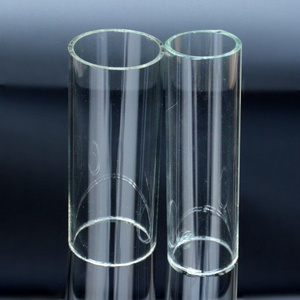

Borosilicate glass tube 3.3

Color: clear

Borosilicate COE3.3 glass tubing:

1. Diameter available: 3.5mm~300mm

2. Wall thickness: 0.8mm~12mm

3. Length: 1220mm~3000mm

4. Regular sizes: 9*2, 12*2, 25*4, 28*4, 32*3.2, 32*4, 38*4, 44*4, 51*4, 50*5.

5. The high borosilicate 3.3 glass tube is used forlab equipment, optical, medical, daily glassware, solar energy, test tube, etc.

6. We can supply special dimensions according to request.

Chemical Composition

SiO2: 81%

B2O3: 13%

Na2O+K2O: 4%

Al2O3: 2%

Borosilicate glass tube 3.3

Color: clear

Borosilicate COE3.3 glass tubing:

1. Diameter available: 3.5mm~300mm

2. Wall thickness: 0.8mm~12mm

3. Length: 1220mm~3000mm

4. Regular sizes: 9*2, 12*2, 25*4, 28*4, 32*3.2, 32*4, 38*4, 44*4, 51*4, 50*5.

5. The high borosilicate 3.3 glass tube is used forlab equipment, optical, medical, daily glassware, solar energy, test tube, etc.

6. We can supply special dimensions according to request.

Chemical Composition

SiO2: 81%

B2O3: 13%

Na2O+K2O: 4%

Al2O3: 2%

Chemical Composition

SiO2: 81%

B2O3: 13%

Na2O+K2O: 4%

Al2O3: 2%

SiO2: 81%

B2O3: 13%

Na2O+K2O: 4%

Al2O3: 2%

Specification

|

Physical Performance

|

Numerical Value

|

Unit

|

|

Coefficient of Mean Linear Thermal Expansion(ISO 7991)

|

3.3±0.1

|

10 -6 K -1

|

|

Transformation Temperature

|

525±15

|

°C

|

|

Softening Point (ISO 7884-6)

|

820±10

|

°C

|

|

Working Point (ISO 7884-2, ISO 7884-5)

|

1260±20

|

°C

|

|

Upper Cooling Temperature (ISO 7884-7)

|

560

|

°C

|

|

Lower Cooling Temperature (ISO 7884-7)

|

510

|

°C

|

|

Density at 20°C

|

2.23±0.02

|

g/cm 3

|

|

Thermal Conductivity (20°C--100°C)

|

1.2

|

w/m 2 K

|

|

Specific heat capacity at constant pressure

|

0.8× 10 3

|

J×/Kg@K

|

|

Modulus of elasticity

|

64 × 10 3

|

MPa

|

|

Tensile strength

|

35-100

|

MPa

|

|

Poisson constant

|

0.2

|

|

|

Refractive Index

|

0.92

|

|

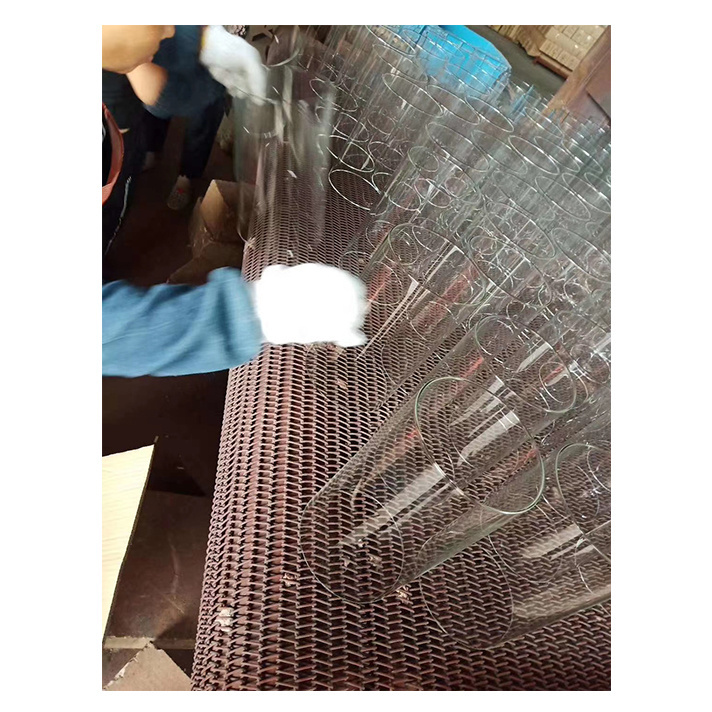

Packing & Delivery

Hot Searches