- Product Details

- {{item.text}}

Quick Details

-

Max Sewing Speed:

-

20-40

-

Max Sewing Thickness:

-

5-10

-

Voltage:

-

220V/380V

-

Weight:

-

2000

-

Name:

-

Ultrasonic embossing laminating machine for mattress

-

Brand name:

-

JYD

-

OEM ODM:

-

Support

-

Main features:

-

High Speed

-

Suitable laminating materia:

-

Non-woven/Cotton

-

Function:

-

Fabric Layers Quilting

-

Advantage:

-

Easy to operate

-

Dilvery time:

-

20 Days

-

Color:

-

Customer's Request

-

Key words:

-

ultrasonic embossing laminating machine for mattress

Quick Details

-

Core Components:

-

ultrasonic generator

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JYD

-

Max Sewing Speed:

-

20-40

-

Max Sewing Thickness:

-

5-10

-

Voltage:

-

220V/380V

-

Weight:

-

2000

-

Name:

-

Ultrasonic embossing laminating machine for mattress

-

Brand name:

-

JYD

-

OEM ODM:

-

Support

-

Main features:

-

High Speed

-

Suitable laminating materia:

-

Non-woven/Cotton

-

Function:

-

Fabric Layers Quilting

-

Advantage:

-

Easy to operate

-

Dilvery time:

-

20 Days

-

Color:

-

Customer's Request

-

Key words:

-

ultrasonic embossing laminating machine for mattress

Supply of multi-specification for making home clothing equipment ultrasonic sewing machine composite embossing machine

|

Model

numb er |

Working

frequency

(max) |

Working

power |

Voltage |

Welding

speed

(max) |

Welding

width

(Max)

|

Controlling

system |

HMI touch

display |

Machine

body

size

(L/W/H:mm) |

Working

whole

size

(L/W/H:mm) |

|

XF20-

L2000-T13 |

20KHz | 39KW |

220V

50/60Hz |

30m/min | 2000mm | PLC | 7 inch | 2900*900*2400 | 5000*900*2400 |

XF20-L2000-T13 is a special multi-layer wireless process cloth laminated ultrasonic composite equipment composed of 7-inch HMI human-computer interaction, touch control, pneumatic system and automatic frequency tracking ultrasonic system. It can be defined according to different widths and patterns of customers; Each group of ultrasonic pressure is controlled by zones and adjusted independently. The utility model has the advantages of high welding precision, cleaning of welding surface lines, strong three-dimensional sense, strong adhesion and convenient pattern replacement.

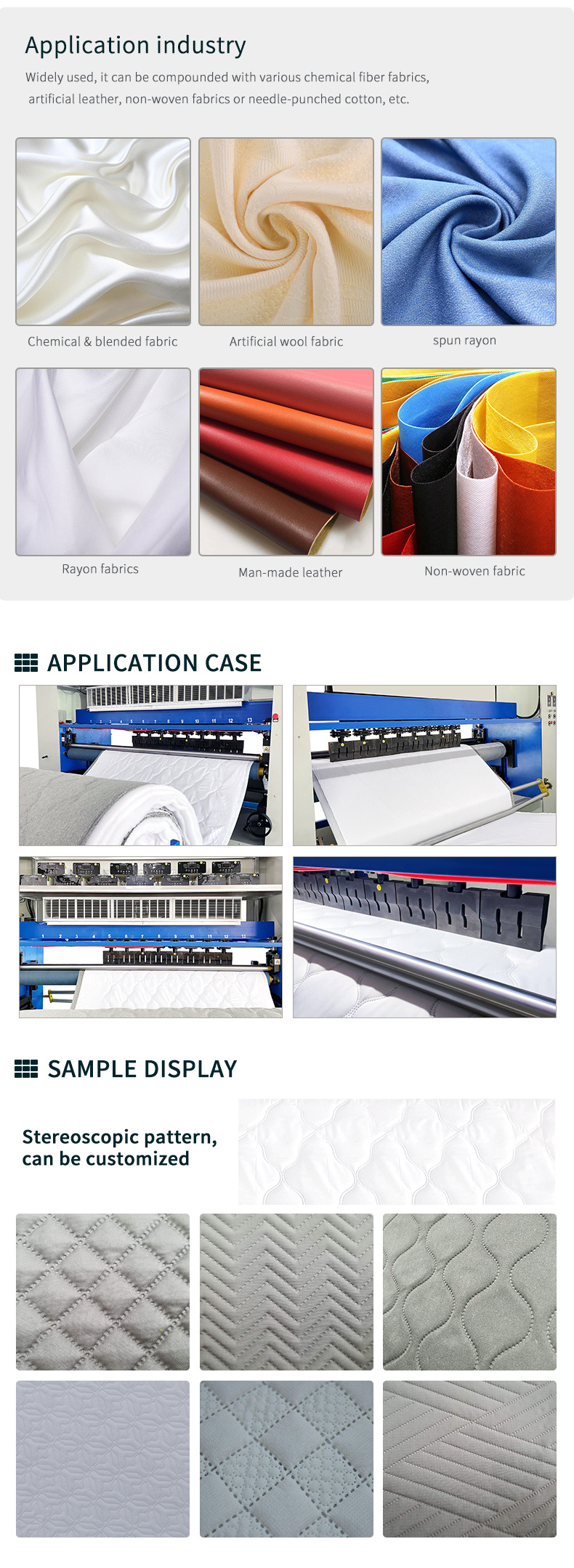

Application:

Scope of application of the machine: air conditioning quilt, wind proof quilt, air conditioning quilt, leather, needle punched cotton, car tarpaulin, car cover, chair cover, luggage, handbag, footwear, shoe materials, clothing cotton clothes, children's clothes, wind jacket;

Pillows, quilt covers, mattresses, bedspreads, cushions, pillows, table mats, tablecloths, curtains, shower curtains, cold proof gloves, baby pads, wet proof urine pads, household accessories, wardrobe, storage, tent wardrobe;

Washing machine cover, Mommy bag, milk bottle, heat preservation bucket bag, electric blanket, cosmetic bag, suit cover, under bed cabinet, sauna cover, shoe hanging bag, storage box bag, PVC pool bottom, etc.

Main Features:

7-inch HMI human-computer interaction, touch control, customizable parameters, RS485 communication function;

The ultrasonic pressure of each group is controlled by zone, adjusted independently, with high welding accuracy and convenient replacement of flower wheel;

Fully automatic control, frequency modulation and speed regulation, torque motor, constant tension, optional deviation correction function, winding neatly;

High ultrasonic welding efficiency; Abnormal monitoring functions such as ultrasonic frequency and power;

High strength flower wheel has good wear resistance and long service life;

Various flower patterns can be developed according to customer needs;

High quality pneumatic and electrical components, stable and reliable quality.