- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

11500 KG

-

Product name:

-

Rod Mill

-

Usage:

-

Grinding Ore, Rock, Artificial Sand

-

Capacity:

-

5-15tph

-

Price:

-

Competitive

-

Advantage:

-

Long Working Life

-

Power:

-

30KW

-

Feeding Size:

-

30mm

-

Discharge size:

-

0-5mm

-

Shipping Way:

-

By Sea, DHL, FedEx, UPS, TNT, EMS

-

Pay Terms:

-

TT, PayPal, Credit Card, Western Union

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

WKD

-

Dimension(L*W*H):

-

1200*2400

-

Weight:

-

11500 KG

-

Product name:

-

Rod Mill

-

Usage:

-

Grinding Ore, Rock, Artificial Sand

-

Capacity:

-

5-15tph

-

Price:

-

Competitive

-

Advantage:

-

Long Working Life

-

Power:

-

30KW

-

Feeding Size:

-

30mm

-

Discharge size:

-

0-5mm

-

Shipping Way:

-

By Sea, DHL, FedEx, UPS, TNT, EMS

-

Pay Terms:

-

TT, PayPal, Credit Card, Western Union

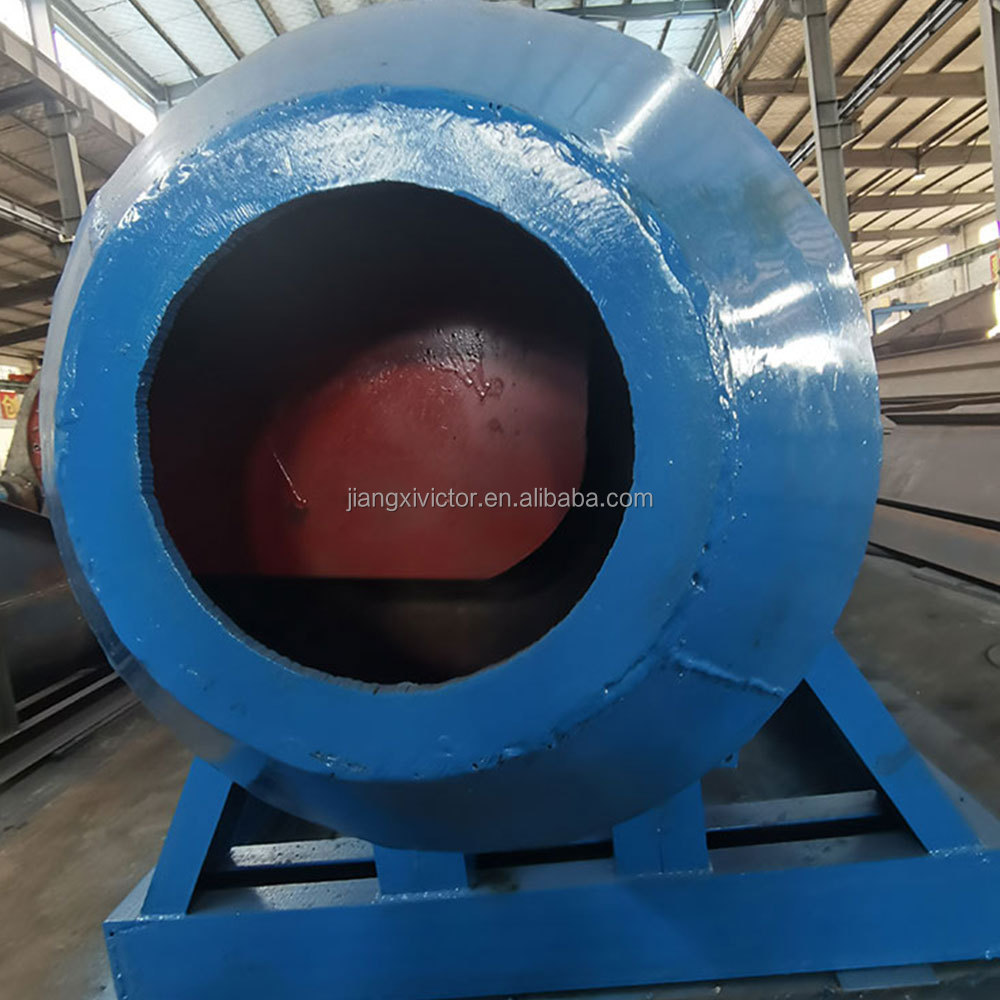

Product Overview

Centre Drive Ball Mill

Ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc. And the ball mill can grind various ores and other materials with dry type and wet type. There are two kinds of ball mill, grid type and overflow type due to different ways of discharging material.

Working Principle

This machine is a horizontal cylindrical rotating device, driven by external gears, with two compartments and a grid type ball mill.

The material enters the first chamber of the mill uniformly through the feeding device through the feeding hollow shaft screw. There is a stepped lining plate or corrugated lining plate in this chamber, which contains steel balls of different specifications. The rotation of the cylinder generates centrifugal force to bring the steel balls to a certain height before falling, causing heavy impact and grinding on the material.

After the material reaches rough grinding in the first warehouse, it enters the second warehouse through a single-layer partition plate. The warehouse is embedded with a flat lining plate and steel balls inside, which further grind the material.

The powder is discharged through the discharge grate to complete the grinding operation.

Main Features

As the selection of bearings is from the perspective of technology, the bearing capacity is much higher than the load of the mill at full load, so the service life of bearings is normally higher than the service life of the mill.

Due to the use of cylindrical roller bearings, the equipment reduces frictional resistance and static resistance torque, and the use of hydraulic couplings and gear accelerators, resulting in a 10.7% -40.5% reduction in motor power compared to conventional mills, with significant energy-saving effects.

Only energy-saving can recover the investment cost of the mill within 2-3 years.

Application

Ball mill is mainly used to grind materials in mineral, cement, refractory, chemical industry, etc. Ball mill has dry and wet ways. When wet ball mill works, certain water and other liquid will be added into materials to increase flow ability of materials, so the capacity is increased. When dry ball mill works, capacity is affected because material flow ability is reduced, so absorbing wind device is needed on the outlet of ball mill, and then negative pressure is formed in the ball mill to increase flow ability of material, so the capacity is increased etc.

PRODUCT SPECIFICATIONS

|

Model

|

The chamber speed

(r/min)

|

Ball Load (t)

|

Feed In Size (mm)

|

Feed Out Size (mm)

|

Capacity (t/h)

|

Motor Power (kw)

|

Weight (t)

|

|

900 ×1800

|

38

|

1.5

|

≤ 20

|

0.075-0.89

|

0.65-2

|

18.5

|

3.6

|

|

900 ×3000

|

38

|

2.6

|

≤ 20

|

0.075-0.89

|

1.1-3.5

|

22

|

4.6

|

|

1200 ×2400

|

35

|

3.5

|

≤ 25

|

0.075-0.6

|

1.5-4.8

|

37

|

11

|

|

1200 ×3000

|

35

|

5

|

≤ 25

|

0.075-0.4

|

1.6-5

|

45

|

13.8

|

|

1200 ×4500

|

35

|

7.5

|

≤ 25

|

0.075-0.4

|

1.6-5.8

|

55

|

14

|

|

1500 ×3000

|

27

|

8

|

≤ 25

|

0.075-0.4

|

2-5

|

75

|

15

|

|

1500 ×4500

|

27

|

12

|

≤ 25

|

0.075-0.4

|

3-6

|

95

|

18

|

|

1500 ×5700

|

27

|

15

|

≤ 25

|

0.075-0.4

|

3.5-6

|

130

|

21.7

|

|

1830 ×3000

|

24

|

12

|

≤ 25

|

0.075-0.4

|

4-10

|

185

|

28

|

|

1830 ×6400

|

24

|

23

|

≤ 25

|

0.075-0.4

|

6.5-15

|

210

|

34

|

|

1830 ×7000

|

24

|

25

|

≤ 25

|

0.075-0.4

|

7.5-17

|

245

|

36

|

|

2100 ×6500

|

21

|

31

|

≤ 25

|

0.075-0.4

|

14-26

|

355

|

52.8

|

|

2200 ×7000

|

21

|

37.6

|

≤ 25

|

0.075-0.4

|

15-28

|

400

|

56

|

|

2700 ×7000

|

18

|

61.8

|

≤ 25

|

0.075-0.4

|

18-35

|

710

|

73

|

Details Images

Let us know

1. What kind of stone you want to crushing ? the max size ?

2. what's your expect capacity ?

3. Do you have some request for final products size ?

4. We have gear drive and centre drive type for you choose.

5.We also manufacture fixed and portable gear drive type for you choose.

2. what's your expect capacity ?

3. Do you have some request for final products size ?

4. We have gear drive and centre drive type for you choose.

5.We also manufacture fixed and portable gear drive type for you choose.

SIMILAR PRODUCTS

Hot Searches