- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

China

-

Brand Name:

-

U TECH

-

Year:

-

2021

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

3.4x2.05x2.25m

-

Hollow part volume:

-

100-2000ml, 0.5 cube meter

-

Clamping Force (kN):

-

3200

-

Power (kW):

-

30KW

-

Weight (KG):

-

3000 KG

-

Product name:

-

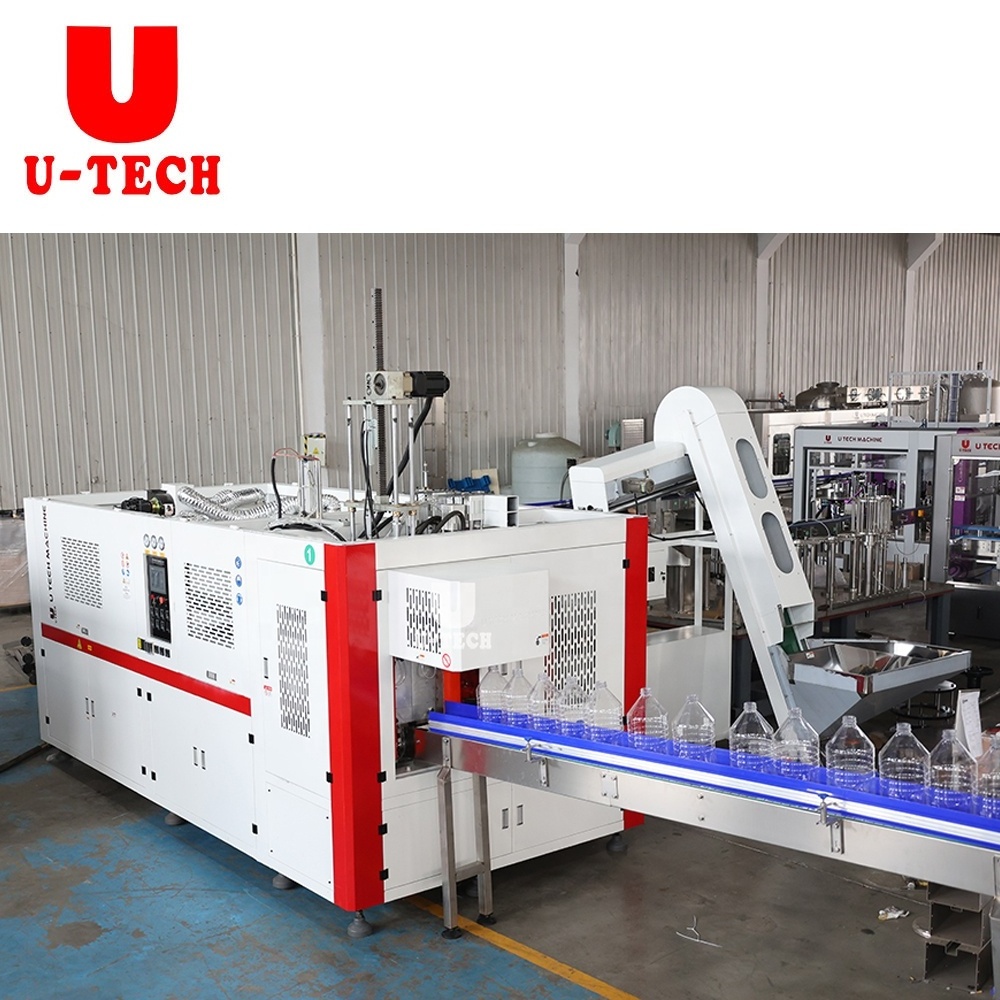

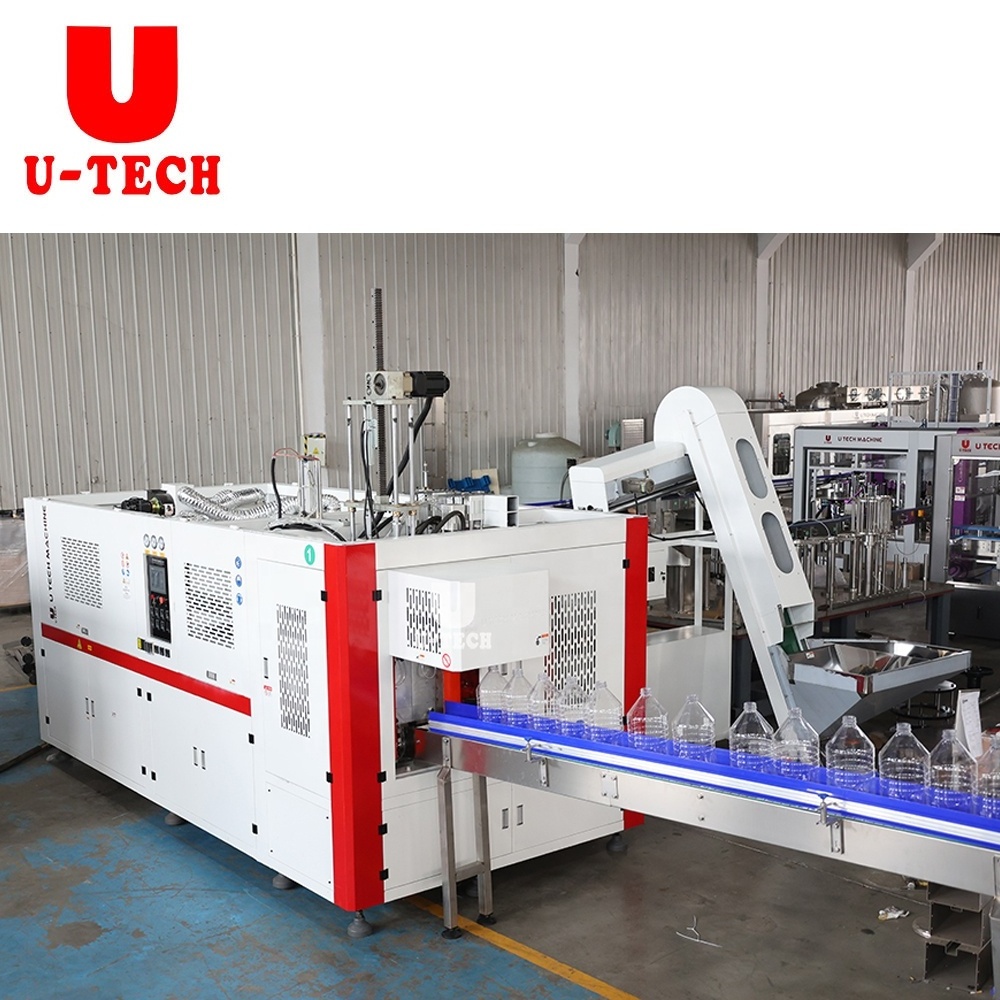

PET bottle blow blowing molding machine

-

Suitable bottle:

-

PET Bottle size 3-10L

-

Raw material:

-

PET Plastic Bottle Preform

-

Air system contains:

-

HP/LP air compressor, air tank, air dryer

-

Auxiliary machine:

-

water chiller, perform loader

-

Light tube quantity:

-

40pcs

-

Material:

-

Ss304/316 is also can be customized

-

Applicable bottle:

-

3-10L Pet Bottle

-

Main markets:

-

Global, mainly in Africa, South East Asia

Quick Details

-

Neck Diameter(mm):

-

28 mm

-

Max.Bottle Diameter(mm):

-

115 mm

-

Max.Bottle Height(mm):

-

320 mm

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

China

-

Brand Name:

-

U TECH

-

Year:

-

2021

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

3.4x2.05x2.25m

-

Hollow part volume:

-

100-2000ml, 0.5 cube meter

-

Clamping Force (kN):

-

3200

-

Power (kW):

-

30KW

-

Weight (KG):

-

3000 KG

-

Product name:

-

PET bottle blow blowing molding machine

-

Suitable bottle:

-

PET Bottle size 3-10L

-

Raw material:

-

PET Plastic Bottle Preform

-

Air system contains:

-

HP/LP air compressor, air tank, air dryer

-

Auxiliary machine:

-

water chiller, perform loader

-

Light tube quantity:

-

40pcs

-

Material:

-

Ss304/316 is also can be customized

-

Applicable bottle:

-

3-10L Pet Bottle

-

Main markets:

-

Global, mainly in Africa, South East Asia

Products Description

Machine Details

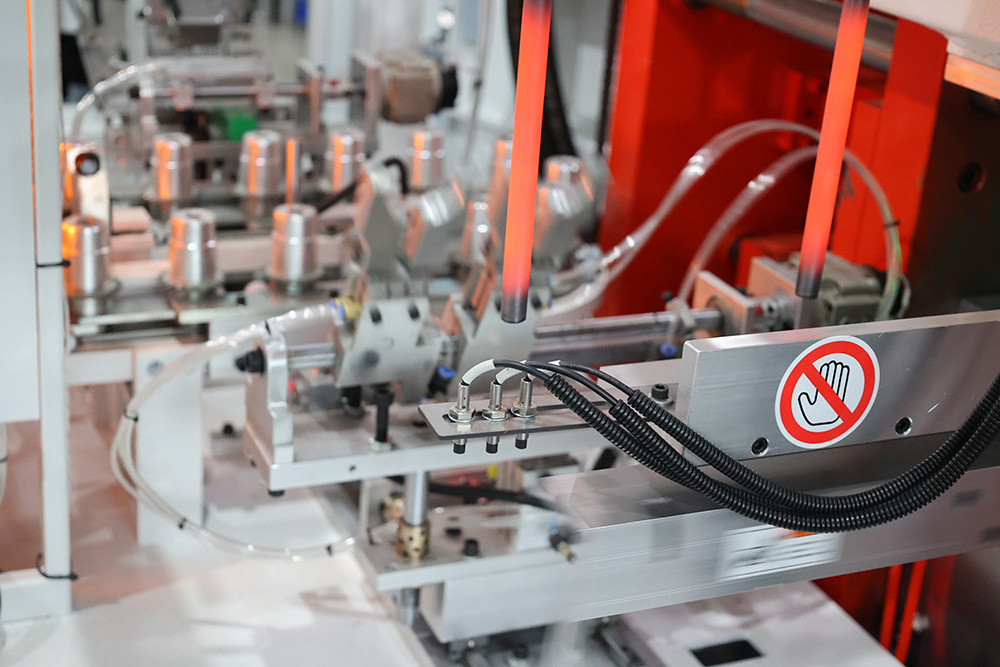

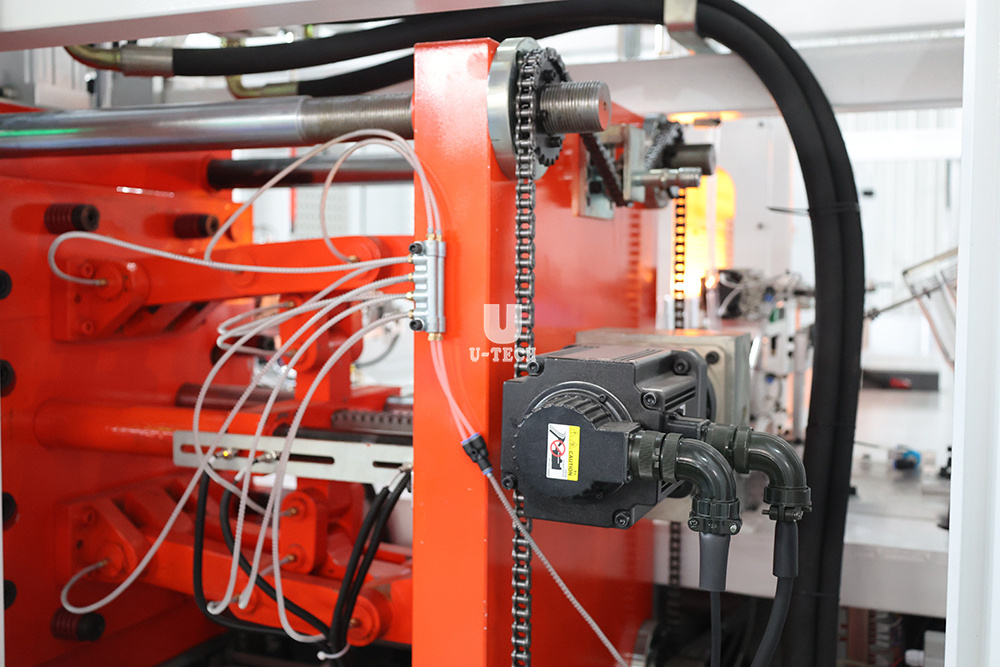

Servo System On Main Transmission.

The transmission adopts servomotor for positioning that can orientate the preform-heating base quickly, accurately and steadily when the machine starts and running.

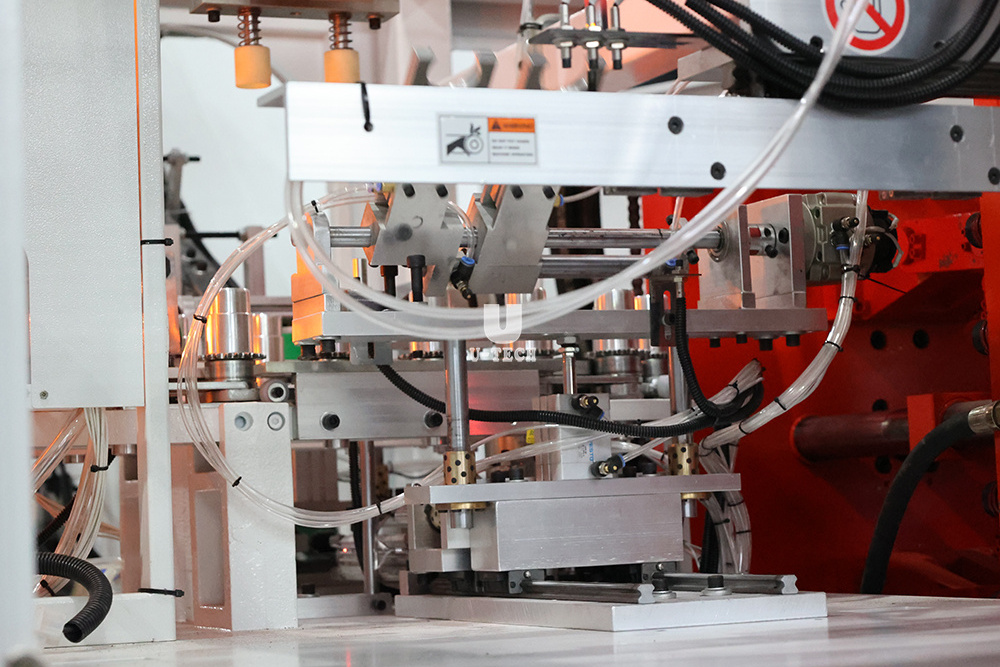

Clamping System & Stretching.

*Adopts servo motor to drive the two cranks to control the clamping system which can shorten the mold-clamping time and improve productivity, and also solve the swelling mold and big joint line problem with the effect of pressurize plate.

* Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

* Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

Working process

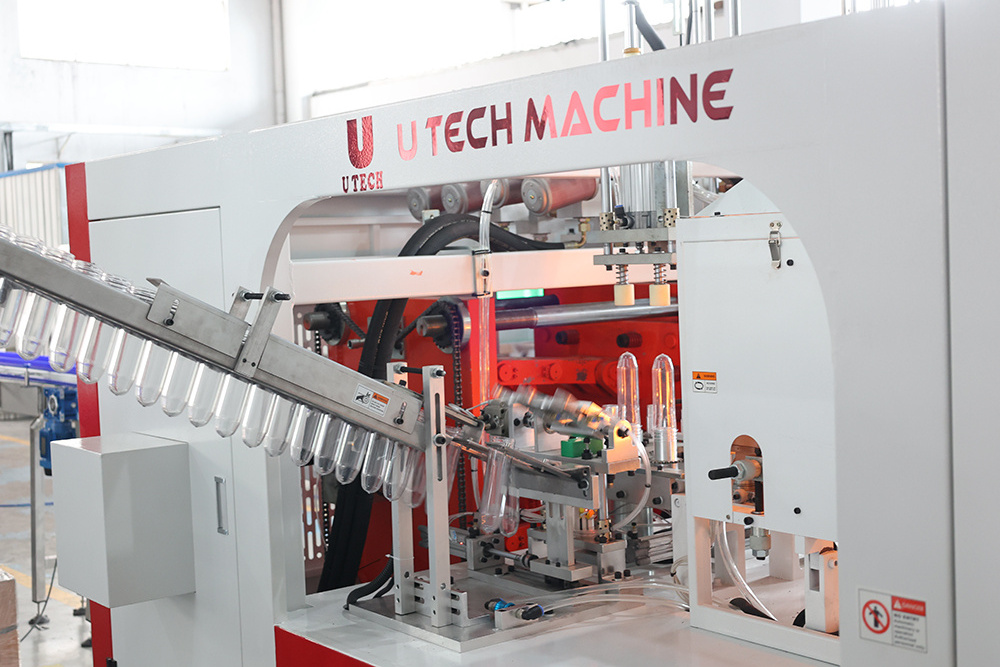

Easy To Change Bottle Shape.

*Drawer type mold structure design is easy for mold changing. Within one hour can change a mold on the condition of same bottle neck diameter.

Auto Preform Unscrambler System.

*Adopts one-way preform-feeding structure and preform-separating by servo motor structure which solve the preform block and abrasion problem.

*There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

*There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

New Heating System.

*Perfect heating system design decrease power consumption.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*Cycle air-cooling system keeps the oven temperature constantly.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*Cycle air-cooling system keeps the oven temperature constantly.

Intelligent Human-Machine Interface.

*Human-machine interface control, easy operate and monitor.

*Live production information supervise, auto record production data everyday

*Failure warning and troubleshooting.

*Live production information supervise, auto record production data everyday

*Failure warning and troubleshooting.

Product Paramenters

|

TYPE

|

ITEM

|

UNIT

|

Technical data

|

|

Container |

Product material

|

/

|

PET

|

|

|

Container volume

|

L

|

3-10L

|

|

|

Theoretic output

|

Psc/hr

|

1000

|

|

|

Preform length

|

MM

|

50-200

|

|

|

Max height of bottle

|

MM

|

320

|

|

Molding |

Preform inner diameter

|

mm

|

15-60

|

|

|

Bottle diameter

|

mm

|

35-110

|

|

|

Max mold plate dimension (L × W)

|

mm

|

380 × 460

|

|

|

Max mold thickness

|

mm

|

200

|

|

Air compressor |

High pressure compressor

|

M3/Mpa

|

1.2/30 × 3set

|

|

|

Locking force

|

KN

|

170

|

|

|

Mold opening stroke (adjustable)

|

mm

|

200

|

|

|

Low pressure compressor

|

M3/Mpa

|

2.0/10 × 1sets

|

|

|

Air dryer

|

M3/Mpa

|

2.0/30 × 1sets

|

|

Main machine electricity

|

Power

|

KW

|

30

|

|

|

Voltage / frequency

|

V/Hz

|

380/50hz

|

Application

Why Choose Us

Certifications

FAQ

Q1:Do you have any reference project?

>> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

>>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years.

Q3: Do you provide customized service?

>> A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on.

Q4:When can I get my machine after I paid?

>> A4:We will deliver the machines on time as the date we agreed both side.

Q5:How can I install my machine when it arrives?

>> A5:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

If you are interested in our machine please contact with me anytime

Hot Searches