- Product Details

- {{item.text}}

Quick Details

-

Equipment Capacity:

-

15, 15

-

Weight (KG):

-

800 KG

-

Product name:

-

Rubber Pyrolysis Oil Machine

-

Function:

-

Extract Oil

-

structural form:

-

Horizontal rotation

-

Reactor life:

-

5~8 Years

-

Cooling method:

-

Water Recycling Cooling

-

Reactor Thickness:

-

16MM/18MM

-

Work Pressure:

-

Normal Pressure

-

Power:

-

20KW

-

Feature:

-

20KW

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

shuguang

-

Marketing Type:

-

New Product 2024

-

Equipment Capacity:

-

15, 15

-

Weight (KG):

-

800 KG

-

Product name:

-

Rubber Pyrolysis Oil Machine

-

Function:

-

Extract Oil

-

structural form:

-

Horizontal rotation

-

Reactor life:

-

5~8 Years

-

Cooling method:

-

Water Recycling Cooling

-

Reactor Thickness:

-

16MM/18MM

-

Work Pressure:

-

Normal Pressure

-

Power:

-

20KW

-

Feature:

-

20KW

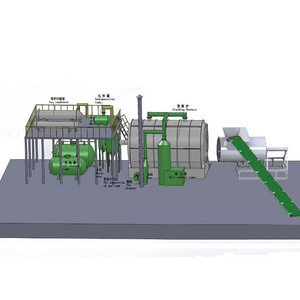

First, the raw materials are put into the reactor, and then seal the feeding in door, later start the machine and the reactor will be rotating and heated by coal, natural gas, wood or electricity. When the temperature reaches the degree of 250 to 280, we will get the crude oil, the oil steam will be continuous produced until the temperature reaches 350-460°C; oil steam will flow through oil gas separator, light component will enter the condensers and meanwhile the heavy oil will be discharged automatically into in heavy oil tank. The liquefied part will be condensed as crude oil, and the part which cannot be liquefied will be transferred by the water seal back to the burning chamber to be reused as heating material

Equipment Features:

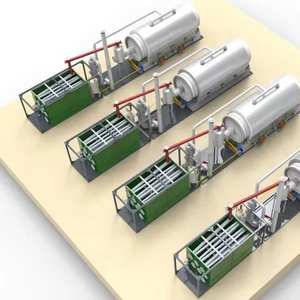

1. Equipment: Adopting one of the most advanced equipment in cracking industry with high degree of automation, high product generation rate and quality, fast production speed, strong safety performance and easy operation.

2. One-piece main furnace shell: one-piece design, good heat preservation effect, and easy to transport and install.

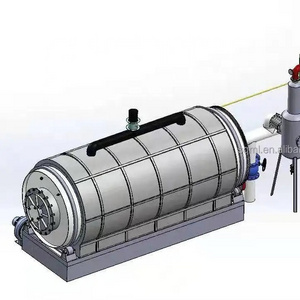

3. The two ends of the main pyrolysis furnace are increased with one-piece lathe-machined bracket, which makes the equipment run more smoothly, reduces the vibration effect at the outlet to a minimum, effectively reduces the problem of oil and gas leakage, and reduces the failure rate of sealing part.

4. Enlarged support wheel: This set of equipment adopts the latest self-adjusting drag wheel, which can effectively decompose the stress point of supporting the furnace body and make the cracking equipment run more smoothly, safely and reliably.

5. Exclusive R&D and design of main furnace anti-sticking wall device, which can effectively reduce the problem of material sticking to the wall in the production process. The device can reduce the cleaning frequency, shorten the maintenance time and cost of the equipment, increase the production time and prolong the service life of the main furnace.

6. Enhanced sealing design, effectively improve equipment safety and environmental protection.

7. Tank cooling system: one-piece box design, easy to transport and install. The cooling pipe is placed in the water and the cooling tower works together to circulate the cooling of condensable oil and gas, with good cooling effect, high oil yield, good oil quality and long service life. The elbows at both ends are easy to dismantle and easy to clean and maintain.

8. Gas recovery system: non-condensable gas can be returned to the furnace through the two-stage safety water seal to fully combust, not only to save combustion 8 burn, and to avoid causing secondary pollution.

9. Safety: fully humane design and automated explosion-proof system control, effectively reducing the incidence of flash explosions.

10.Scope of application: such as waste tyres, waste plastics, waste rubber, domestic waste, kitchen waste, waste paint residue, oil sludge sludge, oilfield waste, electroplating sludge and other organic solid waste.

Production process:

Firstly start the main pyrolysis furnace system, then the material is fed from the staging area by the winch conveyor. Start the frequency conversion quantitative feeding system, open the high-temperature gate valve, and transfer into the main pyrolysis furnace through the feeder. The sludge is heated in the pyrolysis furnace and pyrolysed to produce monomer oil and gas; the oil and gas enters the separation package through the air outlet and is separated from the residual oil here. The light oil and gas continues to rise into the condensation system, condenses into liquid and is collected into the storage tank. A small amount of combustible gas that cannot be condensed into oil enters the heavy cooler above the tank for re-cooling. The non-condensable gas enters the heating system through the buffer tank, self-controlled micro-vacuum system, exhaust gas purification tower and tempering device to burn and provide thermal energy for the device. After the material is heated and decomposed, it is completely carbonised into charcoal residue, which is transferred to the charcoal residue storage box by the airtight slag discharge machine into the winch conveying device. The high heat flue gas discharged from the pyrolysis furnace after the combustible waste gas is heated and recycled through the flue gas waste heat recovery system into the heating system for the second time.