- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Amony

-

Model Number:

-

PCD insert

-

Product name:

-

tungsten carbide pcd inserts

-

Workpiece Material:

-

Steel/Copper/Aluminum/Magnesium/Zinc/Plastic

-

Advantage:

-

High Wear Resistance

-

Certification:

-

ISO9001

-

OEM & ODM:

-

Support

-

MOQ:

-

10 pcs

-

Quality:

-

High Qulity

Quick Details

-

Usage:

-

External Turning Tool

-

Hardness:

-

Super Hard

-

Coating:

-

PCD PCBN CBN

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Amony

-

Model Number:

-

PCD insert

-

Product name:

-

tungsten carbide pcd inserts

-

Workpiece Material:

-

Steel/Copper/Aluminum/Magnesium/Zinc/Plastic

-

Advantage:

-

High Wear Resistance

-

Certification:

-

ISO9001

-

OEM & ODM:

-

Support

-

MOQ:

-

10 pcs

-

Quality:

-

High Qulity

Products Description

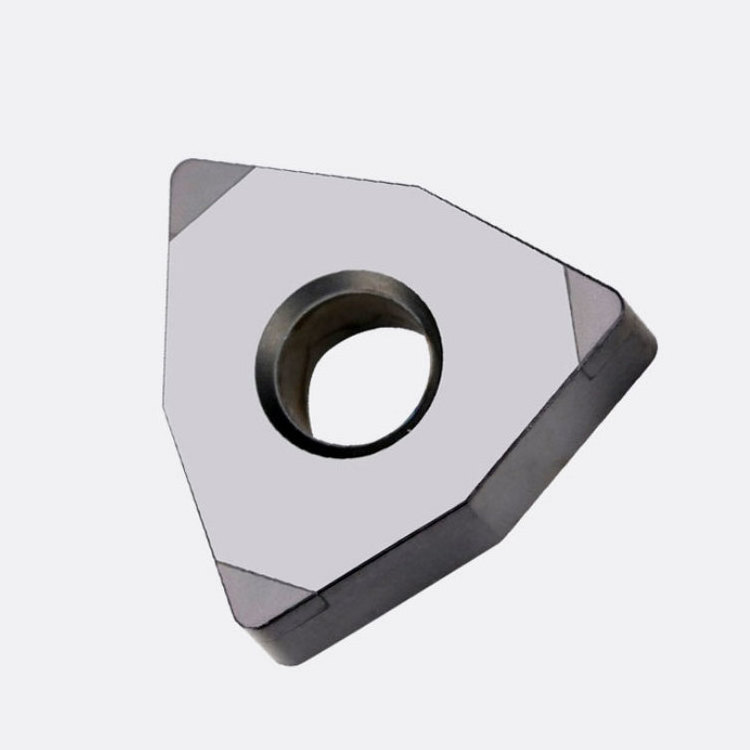

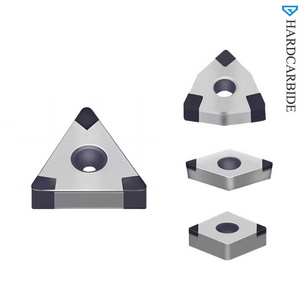

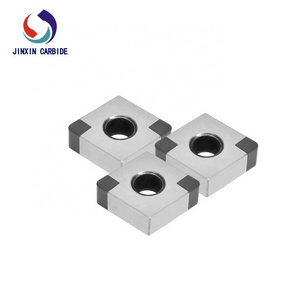

CBN INSERTS

CBN inserts, also known as Cubic Boron Nitride inserts, are cutting tools used in machining processes. These inserts are made from synthetic materials that are extremely hard and durable, making them ideal for cutting and shaping hard materials like hardened steels, cast iron, and superalloys.

CBN inserts are commonly used in industries such as automotive, aerospace, and metalworking, where precision and efficiency are crucial. These inserts are designed to fit into cutting tools, such as turning or milling tools, and they provide excellent heat resistance and wear resistance, resulting in longer tool life and improved productivity.

With their exceptional cutting performance, CBN inserts are a popular choice for achieving high-quality finishes and tight tolerances in various machining applications.

|

Product Name

|

CBN /PCD Inserts

|

110304

|

160404

|

160408

|

|||

|

Fracture toughness

|

9.0

|

|

|

|

|||

|

Hardness

|

3000~5000HV

|

|

|

|

|||

|

Heat resistance

|

1400~1500℃

|

|

|

|

|||

Details Images

HIGH WEAR RESISTANCE

CBN inserts are known for their exceptional wear resistance, making them suitable for machining hard materials such as hardened steels, cast irons, and superalloys.

Heat resistance

These inserts can withstand high temperatures generated during machining processes, ensuring long tool life and consistent performance.

EXCELLENT SURFACE FINISH

The inserts provide a smooth and precise cutting surface, delivering superior surface finish on the workpiece.

COST-EFFECTIVENESS

Despite being a premium tooling solution, CBN inserts offer long tool life, reducing tool change frequency, and overall production costs.

Hot Searches