- Product Details

- {{item.text}}

Quick Details

-

MF:

-

CMS

-

EINECS No.:

-

264.846.4

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

XINTAO

-

Model Number:

-

Carbon Molecular Sieve 260

-

Size:

-

1.1-1.3mm, 1.3-1.6mm

-

Color:

-

Black

-

Shape:

-

Pellet

-

Bulk density:

-

640-680kgs/m3

-

Crush strength:

-

100N/PCS

-

Established year:

-

2002

-

Manufacturer:

-

Yes

-

Certification:

-

ISO9001:2015

-

Keywords:

-

carbon molecular sieve 260

Quick Details

-

CAS No.:

-

744-44-0

-

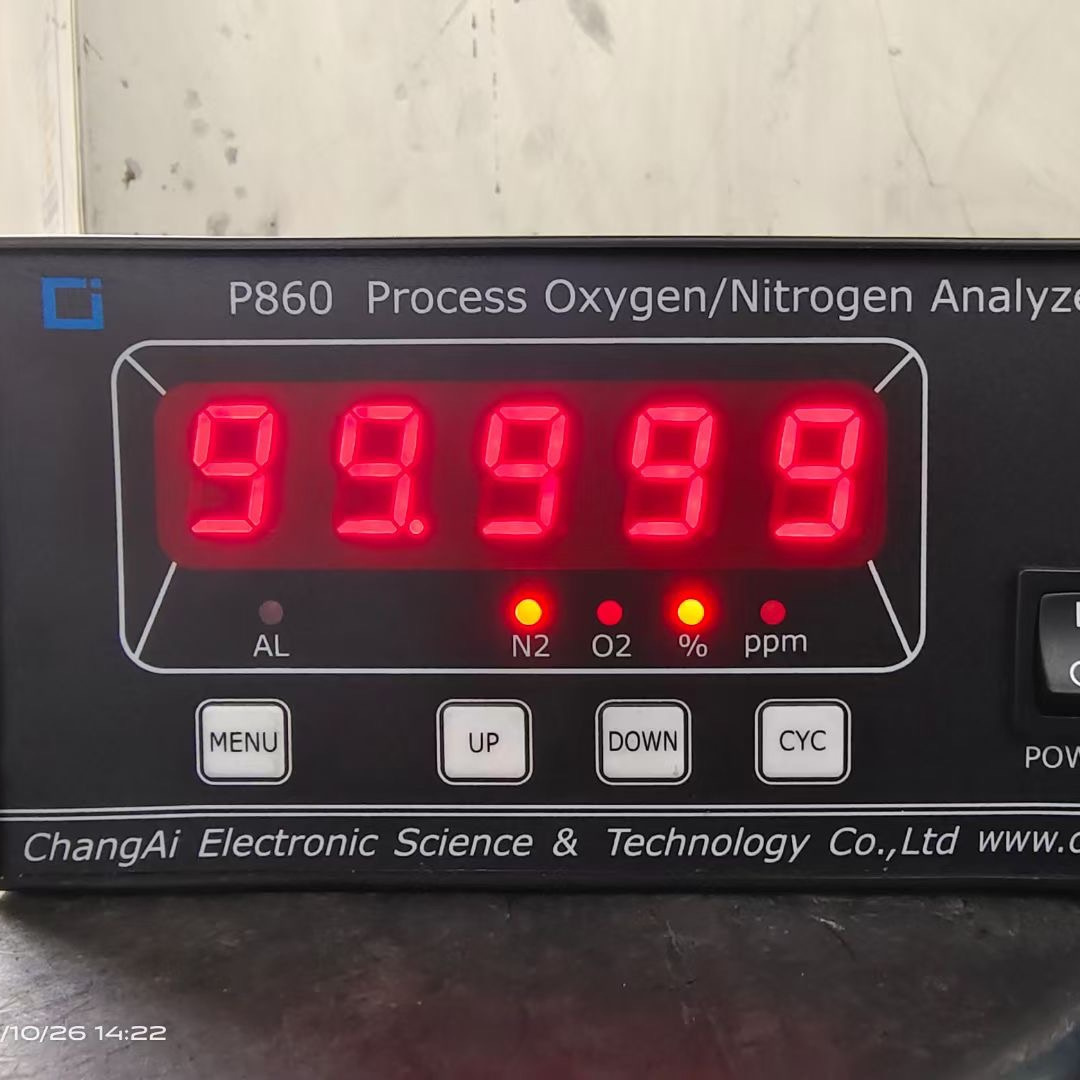

Purity:

-

99.99%

-

Other Names:

-

Molecular Sieve carbon

-

MF:

-

CMS

-

EINECS No.:

-

264.846.4

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

XINTAO

-

Model Number:

-

Carbon Molecular Sieve 260

-

Size:

-

1.1-1.3mm, 1.3-1.6mm

-

Color:

-

Black

-

Shape:

-

Pellet

-

Bulk density:

-

640-680kgs/m3

-

Crush strength:

-

100N/PCS

-

Established year:

-

2002

-

Manufacturer:

-

Yes

-

Certification:

-

ISO9001:2015

-

Keywords:

-

carbon molecular sieve 260

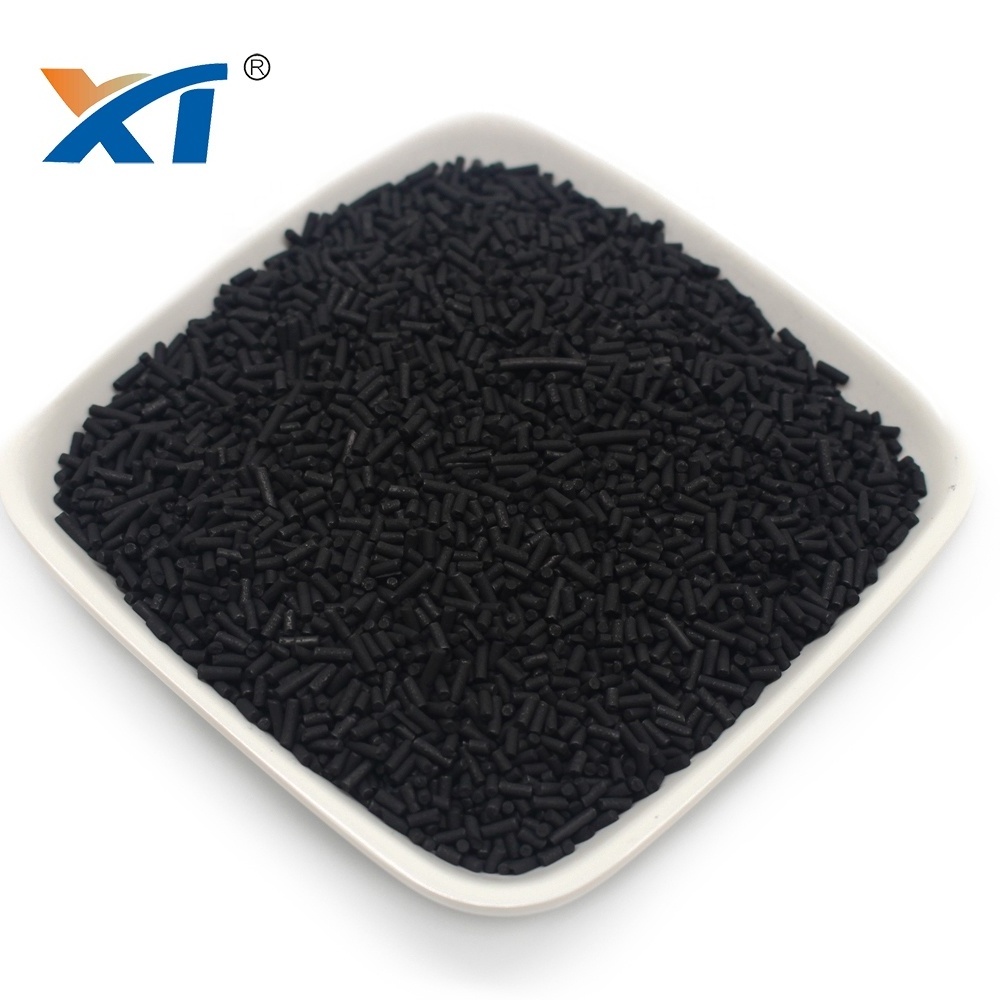

Products Description

The component of carbon molecul

a

r sieve(CMS) is carbon. CMS takes the apperance of cylindrical black soild,contain countless 4 angstrom fine pores, it can be used to seperate air into nitrogen and oxygen.

Carbon Molecular Sieve is the most important element of each and every PSA system and utilized in the production of Nitrogen. Our Carbon Molecular Sieve has capacity of high Nitrogen Yield. It can meet the requirement of almost all types of PSA nitrogen system. The Oxygen molecule will be adsorbed by the solid surface of the CMS and the enriched Nitrogen will be output from the top of the bed to the plant.

The carbon molecualr sieves is widely applied in petroleum chemical industry, the heat treatment of metal, the electronic manufacture and food preservation industries.

Product Paramenters

|

Product

|

Carbon Molecular Sieve

|

|

|

|

|||

|

Appearance

|

Black Pellet

|

|

|

|

|||

|

Diameter

|

0.95mm 1.1-1.3mm, 1.3-1.5mm, 1.5-1.8mm

|

|

|

|

|||

|

Other Names

|

molecular sieve for nitrogen generation

|

|

|

|

|||

|

Crushing Strength

|

>50 (N/PC)(The test temperature≤20℃)

|

|

|

|

|||

|

Dust Level

|

100PPM Max

|

|

|

|

|||

|

Bulk Density

|

630-680(KG/M3)

|

|

|

|

|||

|

Type

|

Adsorbent Pressure(MPa)

|

Nitrogen Purity(N2%)

|

Nitrogen Quantity(NM/h.t)

|

Nitrogen Recovery(N2/AIR %)

|

|||

|

|

|

95

|

470

|

1.7

|

|||

|

|

|

96

|

430

|

1.9

|

|||

|

|

|

97

|

390

|

2.0

|

|||

|

|

|

98

|

350

|

2.1

|

|||

|

|

|

99

|

320

|

2.2

|

|||

|

|

|

99.5

|

260

|

2.3

|

|||

|

|

|

99.9

|

175

|

3.4

|

|||

|

|

|

99.99

|

120

|

4.6

|

|||

|

|

|

99.999

|

75

|

6.5

|

|||

Product Application

PSA Nitrogen Generation Effect

The pressure swing adsorption method uses a high-efficiency and high-selectivity solid adsorbent to preferentially adsorb oxygen or nitrogen to separate nitrogen and oxygen in the air. Carbon molecular sieve adsorbents are commonly used.

The conventional carbon molecular sieve nitrogen generator is equipped with two parallel columns of carbon molecular sieve, which alternately carry out the adsorption cycle of pressurized adsorption oxygen generation and decompression desorption regeneration to realize the separation of nitrogen and oxygen. Nitrogen concentration is 95%~99%.

Xintao's carbon molecular sieve is widely used in nitrogen generator , with high hardness, less ash, uniform particles, and high cost performance. The models selected by customers are usually CMS-240, CMS-260. The nitrogen concentration is 99.5-99.99% and above, which has won a series of praises from customers.

Product Packaging

Hot Searches