- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Matech

-

Car Model:

-

Customized according to customer's requirement

-

Product name:

-

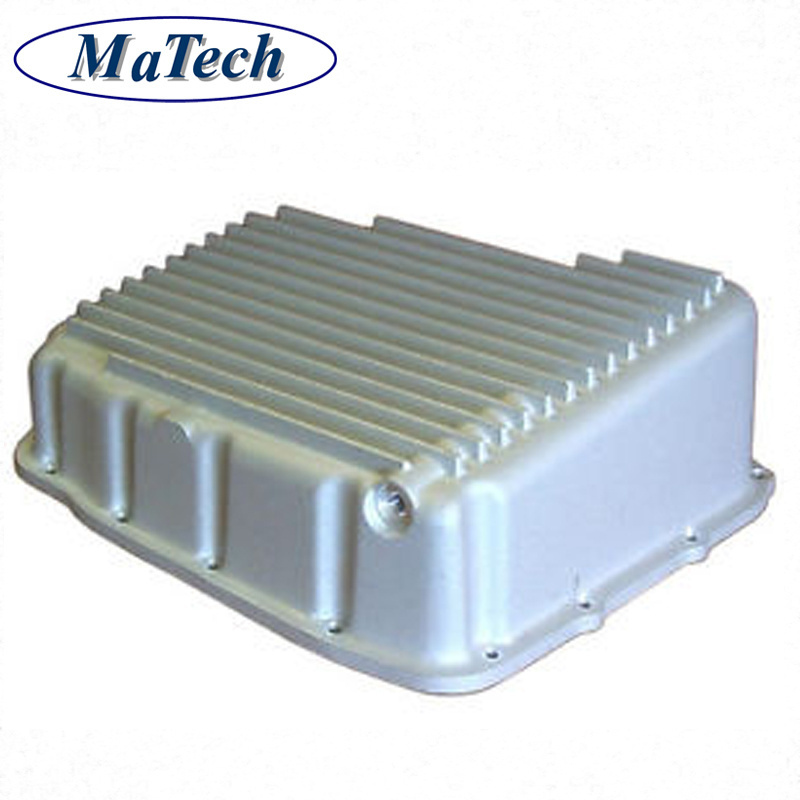

Deep Billet Aluminium Engine Oil Sump Oil Pan

-

Material:

-

aluminum ZL101,A356 or as customer's requirements

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Surface Finished:

-

Sandblasting, painting, polishing or as customer's requirements

-

Drawing Format:

-

pdf,stp,step,stl,etc

-

Certificate:

-

ISO,or as customer's needs

-

Weight:

-

0.05kg~20kg for deep oil pan

-

Package:

-

Big Plastic Bag Inside,Multilayer Wooden Box outside

-

Delivery time:

-

For sample about 45-55 days of deep oil pan

-

Services:

-

Custom metal parts based on your drawings or samples

Quick Details

-

OE NO.:

-

Customized according to customer's requirement

-

Size:

-

Customized according to customer's requirement

-

Warranty:

-

13 months

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Matech

-

Car Model:

-

Customized according to customer's requirement

-

Product name:

-

Deep Billet Aluminium Engine Oil Sump Oil Pan

-

Material:

-

aluminum ZL101,A356 or as customer's requirements

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Surface Finished:

-

Sandblasting, painting, polishing or as customer's requirements

-

Drawing Format:

-

pdf,stp,step,stl,etc

-

Certificate:

-

ISO,or as customer's needs

-

Weight:

-

0.05kg~20kg for deep oil pan

-

Package:

-

Big Plastic Bag Inside,Multilayer Wooden Box outside

-

Delivery time:

-

For sample about 45-55 days of deep oil pan

-

Services:

-

Custom metal parts based on your drawings or samples

SINCERITY QUALITY COMPETENCE ENTERPRISING

Low-pressure casting is a casting method in which liquid alloy is pressed into the mold cavity from bottom to top under pressure, and solidified under pressure to obtain castings. The principle of pressure casting is to pass dry compressed air or inert gas into a sealed crucible, with the help of the pressure acting on the molten metal surface, the molten metal flows along the riser pipe from bottom to top to fill the mold smoothly through the runner , The filling pressure is generally 20-60kPa. When the casting is completely solidified, the gas pressure on the liquid surface is released, so that the non-solidified molten metal in the riser pipe and the runner flows into the crucible by its own weight, and then the mold is opened and the casting is taken out. The production process of low pressure casting includes the following four basic procedures: 1) Metal smelting and preparation of molds or molds. 2) Preparations before pouring: including crucible sealing (fitting sealing cover), slag removal in riser pipe, measuring liquid level, sealing test, mold matching, tightening mold or mold, etc. 3) Pouring: including liquid lifting, filling, pressurization, solidification, pressure relief and cooling, etc. 4) Demoulding: including loose moulding and casting out.

Low pressure casting

can use sand, metal, graphite, etc. The filling process is different from gravity casting such as metal casting and sand casting, and it is also different from pressure casting with high pressure and high speed filling. It has the following

advantages

:

1) Filling with pure liquid metal improves the purity of castings. Since molten slag generally floats on the surface of the molten metal, low-pressure casting is filled with molten metal in the lower part of the crucible through the riser pipe, which completely avoids the possibility of molten slag entering the mold cavity.

2) The molten metal fills smoothly, reducing or avoiding the tumbling, impact, and splashing of the molten metal during filling, thereby reducing the formation of oxide slag.

3) The casting has good moldability. The molten metal is filled under pressure, which can improve the fluidity of the molten metal, which is beneficial to the formation of castings with clear contours and smooth surface, and is more beneficial for the molding of large thin-walled castings.

4) The casting crystallizes and solidifies under pressure, which can be fully fed and the casting structure is dense.

5) Improve the yield of molten metal. Under normal circumstances, there is no need for a riser, and the uncondensed metal in the riser pipe can be refluxed to the crucible for repeated use, which greatly improves the yield of molten metal. Generally up to 90%,

6) Convenient production and operation, good working conditions, high production efficiency, easy to realize mechanization and automation.

General Products Application /Service Area:

We are custom casting aluminum parts based on your drawing or sample. aluminum parts for vehicle, agriculture machine, construction machine, transportation equipment, Valve and Pump system. E.g. Engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve, valve housing ,Fitting , flange, wheel, flywheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

|

Product Name

|

Deep Billet Aluminium Engine Oil Sump Oil Pan

|

|

Main blank Process

|

Permanent Molding /Gravity Casting, Low Pressure Casting

|

|

Blanks Tolerance -Casting Tolerance

|

CT5-7 for Low Pressure Casting

|

|

Applicable Material for Aluminum casting

|

A356.0/ZL101,GAlSi7Mg (3.2371.61)/AlSi7Mg/, A-S7G, Al Si Alloy, Al Cu Alloy ZL201 Al Or according to customer requirements

|

|

Casting Blank Size /Dimensions

|

2 mm-1500mm / 0.08inch-60inch , or according to customer requirements

|

|

Applicable Machining Process

|

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc.

|

|

Machining Tolerance

|

From 0.005mm-0.01mm-0.1mm

|

|

Machined Surface Quality

|

Ra 0.8-Ra3.2 according to customer requirement

|

|

Applicable Heat Treatment

|

T5~T6

|

|

Applicable Finish Surface Treatment

|

Shot/sand blast, polishing, Primer Painting , Powder coating, ED- Coating,

Finish Painting, Anodize (White or Black Color), as customers request. |

|

Lead Time

|

About 50 days for deep oil pan

|