Usage method:

Prepare the liquid to be filled, connect the 220v power supply, adjust the filling time, the interval time and the timer, press the inching switch to test the machine, the motor works normally, press the manual key, and use the foot switch to control the operation of the filling machine. Step on it, the filling machine will work once, and press the automatic key, the filling machine will work automatically and continuously according to the set time.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

87*61*66cm

-

Weight:

-

50

-

Product name:

-

Liquid filling machine

-

Model:

-

LZ-1

-

Power:

-

200W

-

Body material:

-

Stainless steel

-

High temperature resistance:

-

170°

-

Applicability:

-

Beverages, cosmetics, perfume, edible oil, candles, etc

-

Characteristic:

-

Corrosion and high temperature resistance

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

QINBIAO

-

Production Capacity:

-

8 L/min

-

Dimension(L*W*H):

-

87*61*66cm

-

Weight:

-

50

-

Product name:

-

Liquid filling machine

-

Model:

-

LZ-1

-

Power:

-

200W

-

Body material:

-

Stainless steel

-

High temperature resistance:

-

170°

-

Applicability:

-

Beverages, cosmetics, perfume, edible oil, candles, etc

-

Characteristic:

-

Corrosion and high temperature resistance

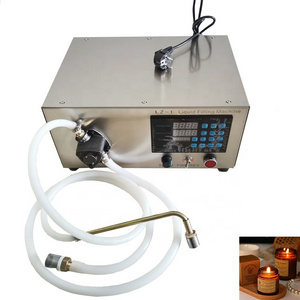

Small Stainless Steel Machine candle pot pump filler wax Melting Candle Filling Machine Wax Melter Candle Maker Machine

Factory Strength Video

:

Wax melter for candle making candle pump filling machine candle making pot wax melter

Products Description

Product Description.

This machine is a special machine for filling oil materials such as crystal candles, butter, tea wax and so on. It has a positive and reverse wax return function. It has large power and is not easy to block. Even if it is blocked, it is very convenient to clean.

This machine adopts the micro motor self-priming cycloidal pump head, and uses the microcomputer to control the working time and intermittent time of the pump. It is a device for quantitative automatic filling and automatic setting of filling time. Suitable for filling more than 5ml oily liquid, such as candle, butter, crystal candle, edible oil, salad oil, etc.

If you need to fill candles, melt the candles into liquid in the matching heating bucket, and then press our operation to

facilitate filling. The trolley can be used for mobile filling.

This machine adopts the micro motor self-priming cycloidal pump head, and uses the microcomputer to control the working time and intermittent time of the pump. It is a device for quantitative automatic filling and automatic setting of filling time. Suitable for filling more than 5ml oily liquid, such as candle, butter, crystal candle, edible oil, salad oil, etc.

If you need to fill candles, melt the candles into liquid in the matching heating bucket, and then press our operation to

facilitate filling. The trolley can be used for mobile filling.

Operating Steps:

1. Filling time adjustment

A. Press the setting key first, the time flashes, and press the increase key 0-9 to set the time required for this bit.

B. Then press the right shift button to position the finger, press the increase button to adjust the time of this bit, and repeat

the operation.

C. Press the unit key to move the decimal point back and forth to determine the time unit

D. Press the Exit key to complete the setting.

2. The intermittent time adjustment is the same as the filling time adjustment

3. Timer adjustment

A. Press the setting key, the timer flashes, press the increase key 0-9 to adjust the number of this bit, press the right shift to adjust the number of other bits, and set the required number

B. Press the mode key, when the light is on, the filling machine will stop working when the specified quantity is filled. When it is not lit, it works continuously and counts continuously.

4. Filling setting Press the filling setting button, and the filling machine starts to work. When the filling reaches the required

amount, press the filling setting button. The time displayed on the filling time is the time required for filling this amount.

1. Filling time adjustment

A. Press the setting key first, the time flashes, and press the increase key 0-9 to set the time required for this bit.

B. Then press the right shift button to position the finger, press the increase button to adjust the time of this bit, and repeat

the operation.

C. Press the unit key to move the decimal point back and forth to determine the time unit

D. Press the Exit key to complete the setting.

2. The intermittent time adjustment is the same as the filling time adjustment

3. Timer adjustment

A. Press the setting key, the timer flashes, press the increase key 0-9 to adjust the number of this bit, press the right shift to adjust the number of other bits, and set the required number

B. Press the mode key, when the light is on, the filling machine will stop working when the specified quantity is filled. When it is not lit, it works continuously and counts continuously.

4. Filling setting Press the filling setting button, and the filling machine starts to work. When the filling reaches the required

amount, press the filling setting button. The time displayed on the filling time is the time required for filling this amount.

The features of this machine are:

1. The filling time can be adjusted to 999 seconds, which is only 99 seconds for similar products.

2. The filling setting function can quickly set the time required for the filling volume

3. The controller of the filling machine is usually displayed in Chinese, and the operation is simple and clear

4. The machine adopts steel pump head, which is high temperature resistant and suitable for filling butter and candles

5. The pump head is easy to disassemble and clean, powerful and not afraid of blockage.

2. The filling setting function can quickly set the time required for the filling volume

3. The controller of the filling machine is usually displayed in Chinese, and the operation is simple and clear

4. The machine adopts steel pump head, which is high temperature resistant and suitable for filling butter and candles

5. The pump head is easy to disassemble and clean, powerful and not afraid of blockage.

|

Model

|

Power

|

Voltage

|

Weight

|

Size

|

Delay range

|

Flow rate

|

|

LZ-1

|

200w

|

220v

|

60kg

|

87cm * 61cm * 66cm

|

0.01s~999.9s

|

20 (cans/minute)

|

|

CY-1D

|

80w

|

220v

|

60kg

|

87cm * 61cm * 66cm

|

0.01s~999.9s

|

5 L/minute

|

More Products

About Us

Our Cooperative Clients

Customer Feedback

Our Certificate

Packaging And Shipping

FAQ

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches