- Product Details

- {{item.text}}

Quick Details

-

Consumption of salt:

-

3.5kg/ kg chlorine

-

energy consumption:

-

4 kwh / kg Cl2

-

NACLO Concentration:

-

0.8%

-

External size:

-

750*1500*1100mm

-

Electrolytic liquid:

-

2.5% - 3% dilute brine

-

Voltage:

-

220V/50Hz

-

Raw Materials:

-

Water, Salt, power

-

Working way:

-

24 hours Automatic

-

Thickness of electrodes:

-

2mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Geemblue

-

Chlorine Output:

-

100 g / h

-

Consumption of salt:

-

3.5kg/ kg chlorine

-

energy consumption:

-

4 kwh / kg Cl2

-

NACLO Concentration:

-

0.8%

-

External size:

-

750*1500*1100mm

-

Electrolytic liquid:

-

2.5% - 3% dilute brine

-

Voltage:

-

220V/50Hz

-

Raw Materials:

-

Water, Salt, power

-

Working way:

-

24 hours Automatic

-

Thickness of electrodes:

-

2mm

Guangzhou Geemblue Environmental Equipment Co., Ltd. is a high-tech enterprise which devoting energy into the development and application of the most advanced water treatment technology. It holds 4 patents of inventions, 15 utility model patents , Appearance patent and a total of 21 software copyrights, besides that, Geemblue is also undertaking 15 research projects of Guangzhou local Government.

The company has been focusing on serving municipal utility plants, sewage treatment plants, power plants, oil platforms, mariculture and food processing plants, etc. and providing quality water treatment equipment and water treatment solutions, so far, the company has been a business partner of many large environmental companies at home and abroad.

Geemblue has always been promoting China's best water treatment equipment and technology, to build the fame of "Made in China". Every movement of Geemblue is for better water treatment equipment and Technology, and for the growth of "Made in China"

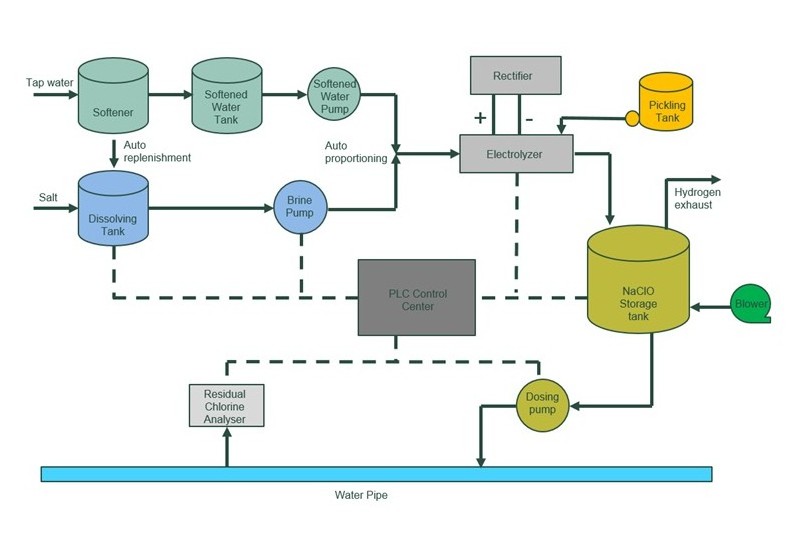

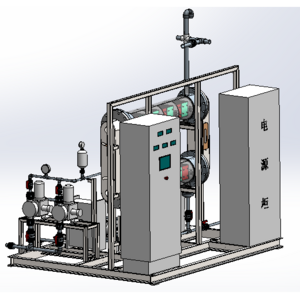

Sodium Hypochlorite Generator(Electrochlorination system)

0.8% Sodium hypochlorite generation system is producing sodium hypochlorite onsite through 3% brine electrolysis(salt and water after saturated), and the whole system is a combination of Softening unit, Filtration unit, Salt dissolving unit, Online proportioning unit, electrolytic unit, rectifier power supply, automatic control systems, storage and dosing unit, etc.

Sodium Hypochlorite is widely used in many water industries. The most applied in drinking water disinfection, on site generation of Sodium hypochlorite is more safely than feeding chlorine gas. Transporting Chlorine gas tank is risky to leakage and lead to explosion.

Product Parameters

Process:

1). Salt will be dissolved in the tank and become saturated brine (25%);

2). Diluted into 3% after filtered ( If use sea water as raw material, it will be treated before electrolysis);

3). Electrolysis in the host machine;

4). The final product- Sodium hypochlorite liquid (5000-7000ppm) in the storage tank;

5). The sodium hypochlorite solution will be injected into the pipe by metering pump;

6). Residual chlorine detective will monitoring the residual chlorine and return feedback to PLC center;

7). PLC center will adjust the speed of dosing pump acc

ording to the preset standard.

Generation principle:

The sodium chloride contained in seawater or brine flow between sets of electrodes (anodes and cathodes) in an electrolyzer.

The chemical reactions which take place in the electrolyzer between chlorine and Sodium hydroxide produced by electrolysis.

In the electrolyzer the sodium chloride is completely dissociated into the ions Na+ and Cl-, causes the following electrochemical and chemical reactions:

Electrode reaction:

at the anode: 2Cl- - 2e → Cl2;

at the cathode: 2H+ + 2e → H2;

Solution reaction:

2NaOH + Cl2 → NaCl + NaClO + H2O

Overall reaction as follow:

NaCl + H2O + DC →NaClO + H2↑

Main Features

1) The only raw material: salt or sea water which is safety and convenient for transportation and storage, without any volatility and toxicity.

2) Bipolar electrode connection mode, reduced the heat yield, as well greatly reduced the production of sodium hypochlorite salt consumption and power consumption

3) Salt consumption< 3.5kg / kg Cl2 (National standard 4.5); power consumption < 4kw /kg Cl2 (National standard 4.5)

4) Siemens PLC and touch screen, full automatic control

5) Cathode life >20 years; Machine life >15 years

Compared with traditional disinfection methods

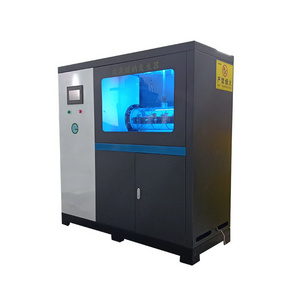

Machine Parts

Marine-grade high-frequency voltage constant current supply , power conversion efficiency >92%,low heat, stable

Machine Parts

Full transparent design of electrolytic cell, easy to observe the brine electrolysis and scale of electrode, for better pickling and protection. The electrolytic cell also equipped with liquid level detection and temperature protection, over current and voltage protection. It will be alarmed and stopped running when any fault of the system.

Pre-Sales Service

* Technical suggestion.

* Proposal solution for your need.

* Compectitive price.

* Factory visiting.

After-Sales Service

* Training how to install and operate the machine.

* Engineers available to service training overseas.

* Trouble shooting support.

* 1 year guarantee for whole system.

Q:Are you a factory or trading company?

A:Factory.

Q:What should I provide before quote?

A:Please supply water sources, water quality, flow rate and application (contact us for more details).

Q:How to pay?

A:TT,Western Union and MoneyGram paypal, etc. 30% deposit before producing, 70% balance before loading by TT.

Q:What is the delivery time?

A:It depends on order quantities. Generally speaking, the delivery time will be within 35 days after payment.

Q:How do you pack the products?

A:Wooden package usually.

Q:How to install after the equipments arriving destination?

A:We will provide detailed technical information to you. If it is necessary, we will send technicians to help you.

91.8% Response Rate

91.8% Response Rate

91.8% Response Rate