Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V, 220/380/400 can be accepted

-

Dimension(L*W*H):

-

N/A

-

Weight:

-

2850

-

Product Name:

-

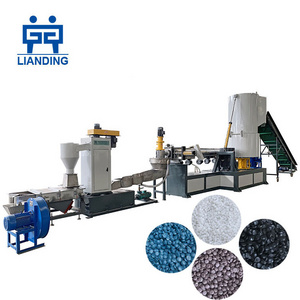

KEDA brand plastic pallets making machine

-

Material Processed:

-

PE Film PP Woven Bags

-

Screw material:

-

40 Cr

-

Barrel material:

-

45#steel

-

Function:

-

pellet,granuling

-

Screw design:

-

single screw

-

Stage:

-

double stage

-

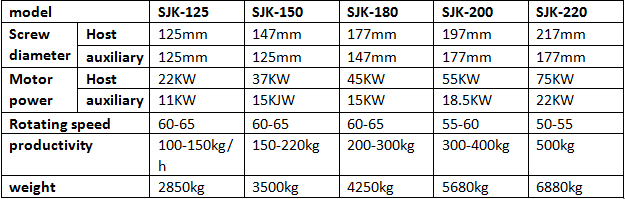

Capacity:

-

100-500kg/h

-

Power:

-

22-75KW

Quick Details

-

Output (kg/h):

-

300 - 400 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

keda

-

Voltage:

-

220V/380V, 220/380/400 can be accepted

-

Dimension(L*W*H):

-

N/A

-

Weight:

-

2850

-

Product Name:

-

KEDA brand plastic pallets making machine

-

Material Processed:

-

PE Film PP Woven Bags

-

Screw material:

-

40 Cr

-

Barrel material:

-

45#steel

-

Function:

-

pellet,granuling

-

Screw design:

-

single screw

-

Stage:

-

double stage

-

Capacity:

-

100-500kg/h

-

Power:

-

22-75KW

Product Description

|

KEDA brand Plastic Recycled Granule Machine/waste plastic extruder

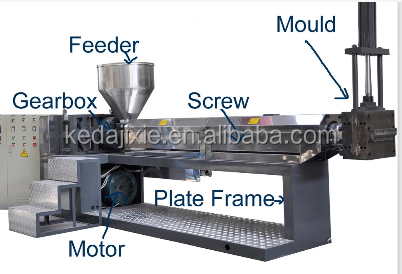

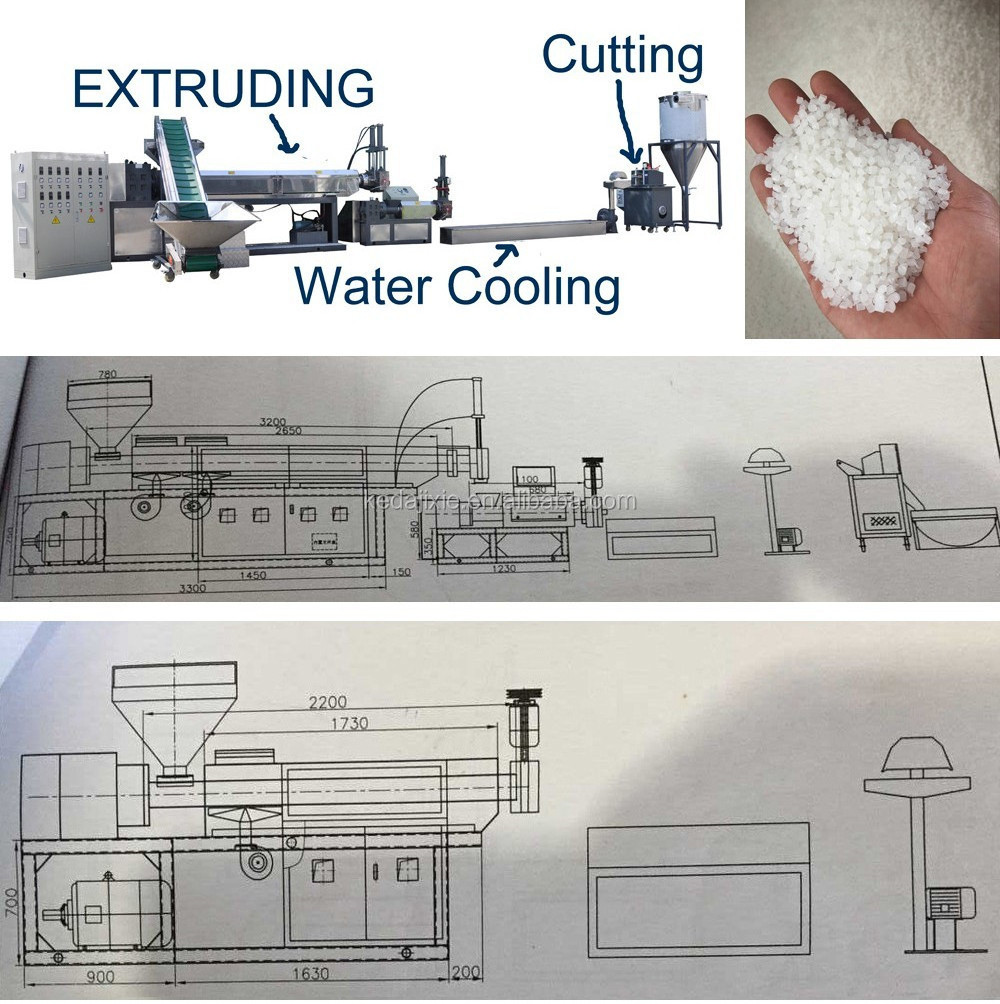

1. The process is as follows: election materials - broken cleaning - automatic feeding - Automatic temperature control heating -melting - mixing - exhaust extrusion - drawing - cooling - automatic cutting. 2. Equipment selection of well-known reducer, to achieve no noise, low failure. 3. Screw and barrel with high-quality carbon steel and alloy steel quenching (optional nickel-based alloy spraying process), so that life expectancy more than five times. 4. The equipment to reduce maintenance rates, to achieve continuous production 24 hours , 5. After the improvement of the feeding port design, it can be put the moisture material with water. |

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

Detailed Images

Our Company

Certifications

Our Service

Packing & Delivery

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hot Searches