- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2400x300x3mm

-

Weight:

-

500 KG

-

Marketing Type:

-

New Product

-

Color:

-

Customers' Requirements

-

Certification:

-

ISO CE

-

Application:

-

separate all kind of material

-

Capacity:

-

3-8ton/h

-

Size:

-

Customized Size

-

Advantage:

-

High Separation Efficiency

-

Quality:

-

High Reputation

-

Price:

-

Negotiable

-

Name:

-

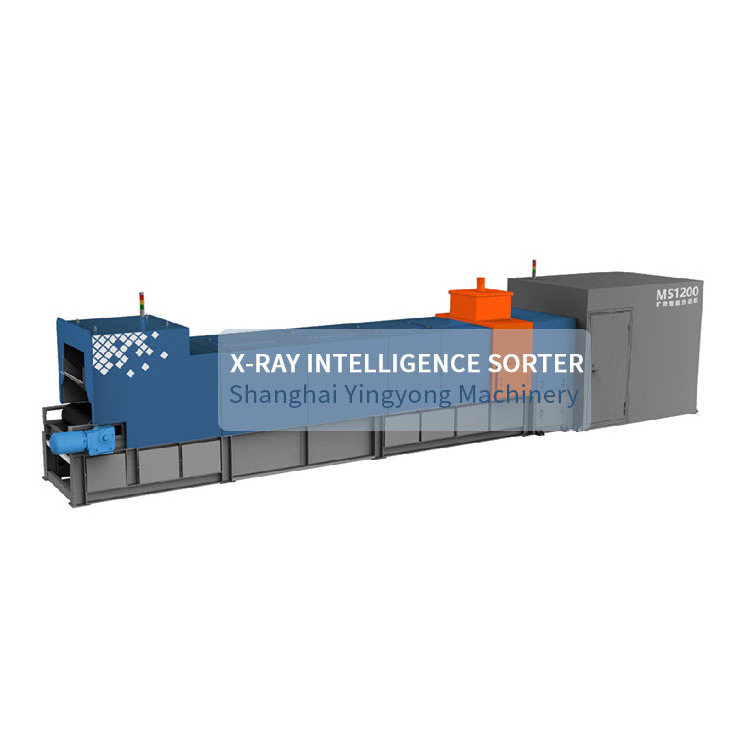

X-ray separator

-

Product name:

-

Coal gangue sorter

Quick Details

-

Production Capacity:

-

According to specifications

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

yingyong

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2400x300x3mm

-

Weight:

-

500 KG

-

Marketing Type:

-

New Product

-

Color:

-

Customers' Requirements

-

Certification:

-

ISO CE

-

Application:

-

separate all kind of material

-

Capacity:

-

3-8ton/h

-

Size:

-

Customized Size

-

Advantage:

-

High Separation Efficiency

-

Quality:

-

High Reputation

-

Price:

-

Negotiable

-

Name:

-

X-ray separator

-

Product name:

-

Coal gangue sorter

Product Description

Mineral intelligent sorting system

The intelligent ore sorting system is a fully automatic equipment that utilizes machine vision, deep learning, automation control, mechatronics integration, high-performance computing, and big data technologies. It simulates human visual perception and brain function by different spectral imaging to distinguish the surface corrosion color, texture, fluorescence, energy spectrum, X-ray transmittance, and other features of the ore. It can rapidly and accurately perform qualitative and quantitative analysis of the ore and effectively select the desired ore.

Green Environmental Protection.

No water needed, no medium required, no coal slurry produced, no toxic and harmful substances used, and no toxic and harmful gases generated.

High sorting accuracy

With the help of high-precision detectors, multi-technology fusion, AI algorithms, and high-precision control systems, precise spraying can be achieved.

Low energy consumption

By adopting centroid air-blowing technology, the loss of high-pressure gas is greatly reduced.

High intelligence

The system runs fully automatically, with remote data transmission and remote fault diagnosis, achieving unmanned operation.

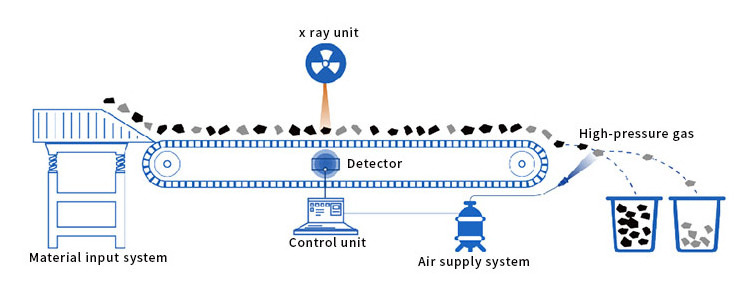

Work Principle

1.The lump coal or ore block is uniformly spread through the feeding/belt device, and transferred by the conveyor belt to the position of the X-ray recognition system.

2.The X-ray recognition system utilizes XRT (X-ray transmission imaging) technology to automatically collect X-ray images of clean coal and gangue, or high/low grade mineral blocks and identify them.

3.The system integrates high-speed computing units and an array of high-pressure gas jet devices to automatically sort mineral blocks based on the image recognition results.

4.Adopting AI (Artificial Intelligence) algorithm, the system utilizes machine learning to continuously improve the recognition accuracy.

Application

Non-ferrous metal ores:antimony, gold, copper, lead, zinc, tungsten, molybdenum, tin, nickel, vanadium, titanium, etc.

Ferrous metal ores: wolfram, iron, manganese, chromium, etc.

Precious metals: gold, silver, etc.

Fluorescent ore: scheelite, fluorite, calcite, Malayite, Zircon, lepidolite, dolomite, stratocite, icelandite, opal, massive fluorite, diamond, etc.

Others: Special energy uranium ores, rare earth ores, non-metallic ores, and other rare metals.

Product Display

MIS-K Series Coal Gangue Intelligent Separator

1. MS-K series coal gangue intelligent separator is a fully automatic intelligent mineral sorting equipment independently developed and manufactured by Tsinghua Tongfang Co., Ltd. for the coal series and kaolin sorting industry.

2. The equipment mainly uses XRT technology and integrates machine vision technology to automatically identify coal gangue within a certain particle size range, distinguishing kaolin and waste stones, and using an array of high-pressure air jets for individual sorting, thus achieving the purpose of intelligent sorting.

3. The equipment has the characteristics of high sorting accuracy, large processing capacity, environmental protection, safety and stability, etc. It can effectively replace the existing manual sorting method and improve the comprehensive utilization rate of coal gangue resources.

2. The equipment mainly uses XRT technology and integrates machine vision technology to automatically identify coal gangue within a certain particle size range, distinguishing kaolin and waste stones, and using an array of high-pressure air jets for individual sorting, thus achieving the purpose of intelligent sorting.

3. The equipment has the characteristics of high sorting accuracy, large processing capacity, environmental protection, safety and stability, etc. It can effectively replace the existing manual sorting method and improve the comprehensive utilization rate of coal gangue resources.

|

Product Model

|

MS1200K

|

MS2000K

|

|

|

Applicable particle size (mm)

|

300-50

|

|

|

|

Capacity (t/h)

|

100

|

200

|

|

|

Equipment size (m)

|

12.3 (length) x2.8 (width) x2.9 (height)

|

12.5 (length) x3.6 (width) x3 (height)

|

|

|

Machine power (kW)

|

40

|

65

|

|

|

Equipment voltage and frequency

|

AC380V/660V/1140V,50Hz

|

|

|

|

Air supply pressure (MPa)

|

0.55-0.8

|

|

|

|

Ambient temperature (°C)

|

-15-+40

|

|

|

|

Staff Member

Annual absorbed dose (mSv/year) |

≤1

|

|

|

|

Boundary dose rate (uSv/h)

|

≤1, @10cm on the surface of the equipment shell

|

|

|

MS-C Series Lump Coal Intelligent Separator

1. The MS-C series lump coal intelligent sorting machine is a fully automatic intelligent mineral sorting equipment independently developed and manufactured by Tsinghua Tongfang Co., Ltd. to meet the demands of the coal industry.

2. The equipment adopts XRT technology to automatically identify lump coal within a certain particle size range, distinguishing between clean coal and coal gangue, and using an array of high-pressure air jets for individual sorting, thereby achieving the goal of intelligent dry sorting. It also distinguishes kaolin and waste stones, and uses an array of high-pressure air jets for individual sorting, thereby achieving the goal of intelligent sorting.

3. The equipment features high sorting accuracy, large processing capacity, green and environmentally friendly operation, safety and stability. It can effectively replace existing manual coal selection methods such as manual sorting, jigging, and heavy-medium separation, and reduce the operating costs of coal preparation plants.

2. The equipment adopts XRT technology to automatically identify lump coal within a certain particle size range, distinguishing between clean coal and coal gangue, and using an array of high-pressure air jets for individual sorting, thereby achieving the goal of intelligent dry sorting. It also distinguishes kaolin and waste stones, and uses an array of high-pressure air jets for individual sorting, thereby achieving the goal of intelligent sorting.

3. The equipment features high sorting accuracy, large processing capacity, green and environmentally friendly operation, safety and stability. It can effectively replace existing manual coal selection methods such as manual sorting, jigging, and heavy-medium separation, and reduce the operating costs of coal preparation plants.

|

Product Model

|

MS1200K

|

MS2000K

|

|

|

Applicable particle size (mm)

|

300-50

|

|

|

|

Capacity (t/h)

|

100

|

200

|

|

|

Equipment size (m)

|

12.3 (length) x2.8 (width) x2.9 (height)

|

12.5 (length) x3.6 (width) x3 (height)

|

|

|

Machine power (kW)

|

40

|

65

|

|

|

Equipment voltage and frequency

|

AC380V/660V/1140V,50Hz

|

|

|

|

Air supply pressure (MPa)

|

0.55-0.8

|

|

|

|

Staff Member

Annual absorbed dose (mSv/year) |

≤1

|

|

|

|

Boundary dose rate (uSv/h)

|

≤1, @10cm on the surface of the equipment shell

|

|

|

MS-NF Series Metal/Industrial Mineral Intelligent Separator

1. The MS-NF series intelligent sorting machine for metal and industrial minerals is a fully automatic intelligent mineral sorting equipment independently developed and manufactured by Tsinghua Tongfang Co., Ltd.

2. The equipment mainly uses XRT technology and can integrate machine vision technology to automatically identify metals and industrial minerals within a certain particle size range. It utilizes an array of high-pressure air jet devices for individual sorting, thus achieving the goal of intelligent dry sorting.

3. The equipment can serve the purpose of discarding waste in advance, improving the grade of selection, etc., and bringing economic value to mineral processing enterprises.

4. Applicable mineral types: lead-zinc ore, tin ore, tungsten ore, ore, copper ore, platinum ore, phosphate rock, etc.

3. The equipment can serve the purpose of discarding waste in advance, improving the grade of selection, etc., and bringing economic value to mineral processing enterprises.

4. Applicable mineral types: lead-zinc ore, tin ore, tungsten ore, ore, copper ore, platinum ore, phosphate rock, etc.

|

Product Model

|

MS1200K

|

MS2000K

|

|

|

Applicable particle size (mm)

|

300-50

|

|

|

|

Capacity (t/h)

|

100

|

200

|

|

|

Equipment size (m)

|

12.3 (length) x2.8 (width) x2.9 (height)

|

12.5 (length) x3.6 (width) x3 (height)

|

|

|

Machine power (kW)

|

40

|

65

|

|

|

Equipment voltage and frequency

|

AC380V/660V/1140V,50Hz

|

|

|

|

Air supply pressure (MPa)

|

0.55-0.8

|

|

|

|

Ambient temperature (°C)

|

-15-+40

|

|

|

|

Staff Member

Annual absorbed dose (mSv/year) |

≤1

|

|

|

|

Boundary dose rate (uSv/h)

|

≤1, @10cm on the surface of the equipment shell

|

|

|

Successful Cases

Scrap aluminum sorting case site in Jiangxi

Particle size range: 30-200mm ; Processing capacity: 150t/h ;

Gangue in coal: <3% ; Gangue with coal: <3% ; Economic benefits: 12 million yuan/year

Gangue in coal: <3% ; Gangue with coal: <3% ; Economic benefits: 12 million yuan/year

The Coal-Series Kaolin Sorting Project in Shanxi Province.

Particle size range: 50-200mm

Processing capacity: 100t/h

Kaolin content: 30%

Accuracy: >95%

Processing capacity: 100t/h

Kaolin content: 30%

Accuracy: >95%

Coal Sorting Project in Inner Mongolia

Particle size range: 30-150mm

Processing capacity: 120t/h

Gangue in coal: <3%

Gangue with coal: <3%

Economic benefits: 10 million yuan/year

Processing capacity: 120t/h

Gangue in coal: <3%

Gangue with coal: <3%

Economic benefits: 10 million yuan/year

Certifications

focuses on applications of machine vision technology to improve and provide innovation in ore sorting. Awarded the title of the Seed Unicorn Enterprise from Jiangxi province in 2018 and the World's Advanced Ore Sorting Enterprise from the Chinese Nonferrous Metal Association.

Our Business

We has promoted progressions in utilizing intelligent machines in China's mining industry: increasing efficiency, helping customers cut costs, and making the ore sorting process more environmentally friendly.

As of today

, HPY Sorting has sold more than 300 machines, making it the market leader in China with a 73% domestic market share.

Products are self-developed, protected by patent law, invention patents, utility model patents, software copyrights. HPY Sorting has over 100 types of patents.

FAQ

1) Q: Which type should I use for my recycling plant?

A: In order to recommend the most suitable model, please let us know the material situation , including the composition ,size,handling capacity and expected separation result .

2) Q: How to make the payment?

A: We accept the payment by T/T or Western Union or Cash, L/C. For T/T, the customer can choose 100% in advance or 30% in advance, and pay the 70% balance before shipment.

3) Installation

A:Installation manual and a guide video will be provided. What's more, We can also send engineers to your site for instructing installation, debugging machine and training workers once you required.

4) Warranty

A:During the one year guarantee period, we change those damaged original components and parts free.

5) Technical Guidance all life

A:Just call us if any problem you encountered when the whole line in operation, our technician will give you a solution within 24 hours.

Hot Searches