- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Park

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yinrong

-

Model Number:

-

YR-SZG-01

-

Type:

-

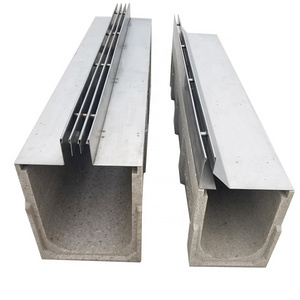

Drainage ditch

-

Product name:

-

Resin drainage ditch

-

Keywords:

-

U-shaped drainage ditch

-

Material:

-

Resin

-

Logo:

-

Customized Logo Acceptable (Extra Charges)

-

Size:

-

Customized Size

-

Color:

-

silvery/as your request

-

Shape:

-

Customized

-

Service:

-

Video Guidance

-

MOQ:

-

1

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

3D model design, Others

-

Application:

-

Park

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yinrong

-

Model Number:

-

YR-SZG-01

-

Type:

-

Drainage ditch

-

Product name:

-

Resin drainage ditch

-

Keywords:

-

U-shaped drainage ditch

-

Material:

-

Resin

-

Logo:

-

Customized Logo Acceptable (Extra Charges)

-

Size:

-

Customized Size

-

Color:

-

silvery/as your request

-

Shape:

-

Customized

-

Service:

-

Video Guidance

-

MOQ:

-

1

Products Description

Features:

1. Fast installation, which helps shorten the construction period

2. Smooth U-shaped inner wall prevents garbage accumulation and smooth drainage

3. The construction ditching depth is shallow, the slope finding is simple, easy to construct, and the installation and

construction speed is fast

4. Strong carrying capacity, in line with EN1433 standard

5. It has the characteristics of high-quality anti-aging, anti-freezing, anti-corrosion and environmental stability, zero

penetration, etc.

1. Fast installation, which helps shorten the construction period

2. Smooth U-shaped inner wall prevents garbage accumulation and smooth drainage

3. The construction ditching depth is shallow, the slope finding is simple, easy to construct, and the installation and

construction speed is fast

4. Strong carrying capacity, in line with EN1433 standard

5. It has the characteristics of high-quality anti-aging, anti-freezing, anti-corrosion and environmental stability, zero

penetration, etc.

Product Paramenters

|

Model

|

Total Wide

|

Total Height

|

Total Length

|

Internal Width

|

Internal Height

|

Trench Cover Width

|

|

U100-150-1000

|

140

|

150

|

1000

|

100

|

118

|

115

|

|

U100-200-1000

|

140

|

200

|

1000

|

100

|

168

|

115

|

|

U150-200-1000

|

190

|

200

|

1000

|

150

|

168

|

170

|

|

U150-250-1000

|

190

|

250

|

1000

|

150

|

218

|

170

|

|

U150-300-1000

|

190

|

300

|

1000

|

150

|

168

|

170

|

|

U200-200-1000

|

240

|

200

|

1000

|

200

|

168

|

220

|

|

U200-250-1000

|

240

|

250

|

1000

|

200

|

218

|

220

|

|

U200-300-1000

|

240

|

300

|

1000

|

200

|

268

|

220

|

|

U250-300-1000

|

290

|

300

|

1000

|

250

|

267

|

270

|

|

U300-300-1000

|

340

|

300

|

1000

|

300

|

250

|

320

|

|

U300-350-1000

|

340

|

350

|

1000

|

300

|

300

|

320

|

|

U300-400-1000

|

340

|

400

|

1000

|

300

|

350

|

320

|

|

U400-400-1000

|

460

|

400

|

1000

|

400

|

342

|

441

|

|

U400-500-1000

|

460

|

500

|

1000

|

400

|

442

|

441

|

A U-shaped resin drainage ditch refers to a channel or trench constructed in a U-shape and made from resin-based materials. This type of drainage ditch is commonly used to manage the flow of water, directing it away from specific areas to prevent flooding and water damage. The use of resin-based materials provides advantages such as corrosion resistance, durability, and potentially lower weight compared to traditional materials like concrete or metal.

Details Images

Daily maintenance:

It is recommended to check the usage of the drainage system regularly, at least once a year.

Check content:

1. Check the fixing condition between the drainage ditch cover and the tank. If the screws fixing the cover are loose, use

special tools to tighten.

2. Clean the collection well, clean the dirt blue, and clean the entrance of the municipal drainage system;

3. Clean the drainage ditch. Remove the cover plate and clean up the debris in the trench;

4. Clean the sediment in the drainage ditch;

5. Repair the damaged part of the drainage ditch body;

6. Use special sealant to repair the joints of the drainage ditch body;

7. Restore all parts and fasten them with screws.

It is recommended to check the usage of the drainage system regularly, at least once a year.

Check content:

1. Check the fixing condition between the drainage ditch cover and the tank. If the screws fixing the cover are loose, use

special tools to tighten.

2. Clean the collection well, clean the dirt blue, and clean the entrance of the municipal drainage system;

3. Clean the drainage ditch. Remove the cover plate and clean up the debris in the trench;

4. Clean the sediment in the drainage ditch;

5. Repair the damaged part of the drainage ditch body;

6. Use special sealant to repair the joints of the drainage ditch body;

7. Restore all parts and fasten them with screws.

Features of resin drainage ditch:

Compressive and bending strength

Resin three-dimensional network molecular structure, and filler reaction can attack strong bonding ability, so it has a high compressive strength and bending strength, the compressive strength of special planning can be as high as 2500kg/cm2

Resistance to acid and alkali

Polyester resin concrete corrosion resistance is strong, on the biological sulfuric acid corrosion and acid soil resistance ability is particularly good.

Corrosion resistant

No pores, no water absorption, all corrosion, damage are blocked outside, can prevent biological growth on its surface, damage; Let no pests have a chance to live. A short time of high concentration of chemical corrosion, because of the high amount of aggregate filling, and no capillary phenomenon, damage will only occur on the surface, will not deepen the internal concrete, damage the structural strength.

Environmental stability

The stability of polyester resin concrete after cement is higher than that of thermoplastic resin.Glassy stability. High strength, environment stability is good, in the domestic classification of green environmental protection materials; In the European Union, it is allowed to recover the rolled gravel to be used again, and even directly as a roadbed material, without the problem of environmental pollution.

Good cold

Weather resistance, even in the harsh environment still will not have the phenomenon of brittle crack or damage.Because of the stability of the molecular structure, with anti-ultraviolet ability, unlike the general engineering plastics because of the ultraviolet formation of material aging, brittle crack phenomenon.Freeze-thaw resistance, not afraid of cold damage, can be safely used in mountain snow areas.

Life is long

Under the correct standard requirements and equipment, there is no restriction on the planning of the service life, related to cement concrete, plastic and other materials, the service life is high, the annual amortized cost is relatively low, so the economic benefit of resin concrete material is far higher than that of other materials.

l

Light weight, accurate scale

High strength/component ratio.For products with the same standard strength, the thickness of the material can be reduced, and the weight of the products can be greatly reduced, making the products lightweight. And reduce transportation, hoisting, excavation and other costs. The plasticity is strong, can produce various accurate shape according to various standard scale.

Easy to process, equipment and stick

It has been proved by the test that after the bending test is broken, the bonding will not crack at the original cracking place. Good for connection, and then improve the overall water tightness.It has the benefits of simple construction and convenient equipment, and it helps to control the construction period.Processing is simple, can be drilled, cut, and other processing.

Smooth surface, free from maintenance

Smooth and fine surface, roughness coefficient n=0.010, good hydraulic characteristics, not easy to accumulate sediment, can reduce The Times of maintenance.Not punctual to high-pressure water scour, on the removal of sediment deposition is more simple, unlike cement concrete, there is a risk of damage, save maintenance costs.

Freezing-thawing resisting

The replacement of the frozen dredge understand the function of the reduced cement, and the impact on the resin concrete is very small, because the resin concrete internal no suction water hole structure, 1600 times of freeze-thaw test did not attack the quality of the function of the change.

Small drainage ditch, also need scientific and technological innovation, advance the quality of products, the resin concrete drainage ditch continued to promote the use of. Now resin concrete drainage ditch can be used in a variety of places, parks, squares, railway stations and so on. As a very important equipment in commercial places, drainage ditch should be required to do the most safe insurance guarantee in planning and construction.

Application

Hot Searches