- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OEM

-

Model Number:

-

E015

-

Type:

-

Custom action figure

-

Size:

-

7 inch

-

Weight:

-

100g

-

Color:

-

Multi color Figure

-

Function:

-

Movable arms &Legs

-

logo:

-

Custom logo printed

-

Usage:

-

Gift ,Decoration ,Collection

-

Process:

-

Injection craft action figure & Painting

-

Feature:

-

Good painting&Eco-friendly material

-

Design:

-

3D Action Figure

Quick Details

-

Style:

-

Cartoon Toy, Military Toy, MODEL TOY

-

Material:

-

PVC

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

E015

-

Type:

-

Custom action figure

-

Size:

-

7 inch

-

Weight:

-

100g

-

Color:

-

Multi color Figure

-

Function:

-

Movable arms &Legs

-

logo:

-

Custom logo printed

-

Usage:

-

Gift ,Decoration ,Collection

-

Process:

-

Injection craft action figure & Painting

-

Feature:

-

Good painting&Eco-friendly material

-

Design:

-

3D Action Figure

Product Description

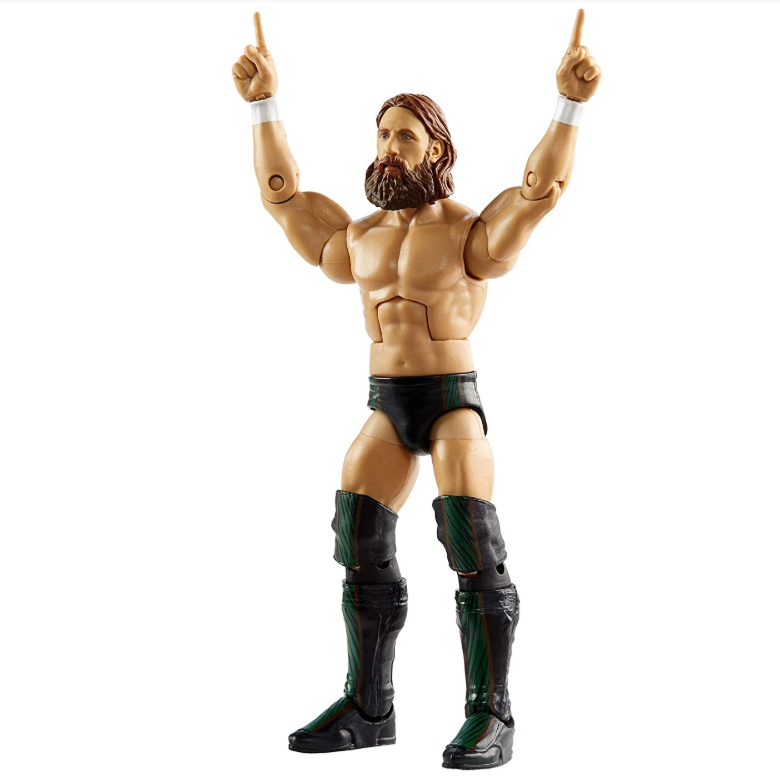

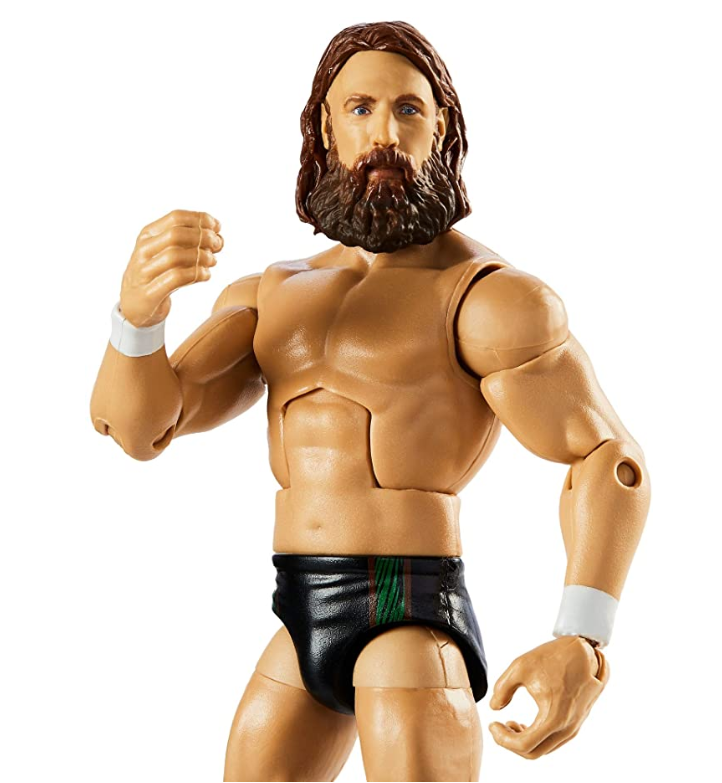

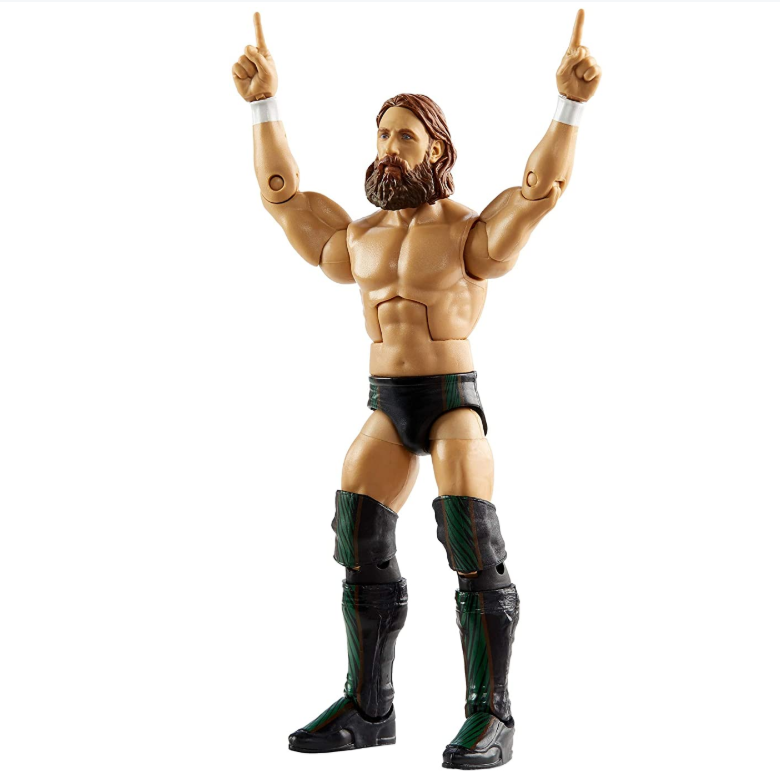

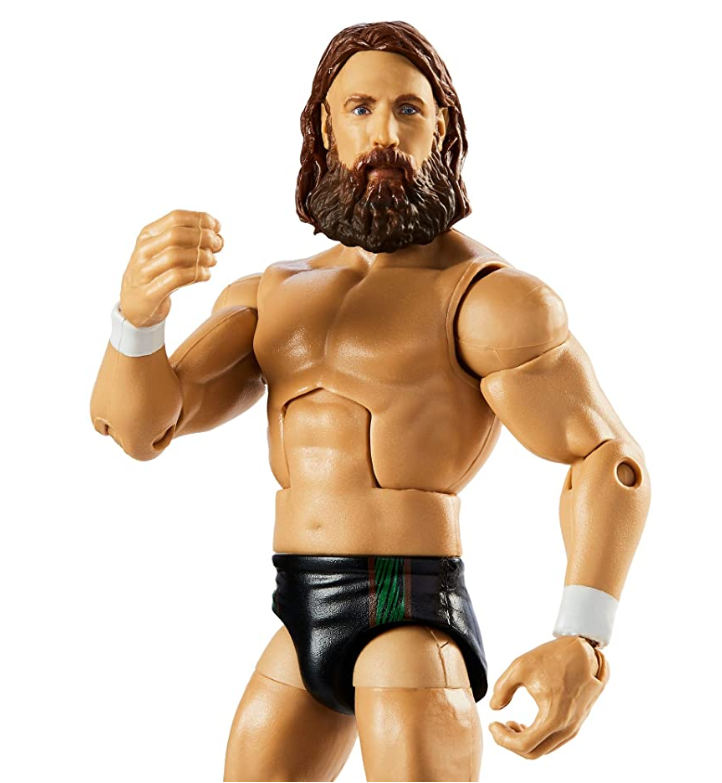

| Production Name | OEM factory make your own design articulated custom action figure |

| Size | 7 inch |

| Painting | Durable painting Figures |

| Material | Eco-Friendly PVC ( Meet Eu Standard ) |

| Sample time | 7-10 days |

| Tooling time | 25-30 days |

| Mass production time | 25-30 days ( depands on the quantity ) |

| Package | Customized toys package |

| Carton size | 45*45*35CM |

| Sample | Free similar vinyl sample can be sent if needed |

Related Products

Toys Production Flow

1.

Clients provide concept art or 3D file and inform special features and action figure toys functions

2.

The

prototype figure is created either by hand or digital by using the concept art and will shows the 3D model of figures from multiple views and angles for approval

3.

Making physical sample and hand painting of the action figure

4.

Part casting from the ready approved prototype , by the way, this is the last opportunity to make any changes to the shape of the toys figure .

5.

The steel tools are created by using

t

he various parts of prototype

6.

Testing toys by using the steel tooling , the first figure toy sample from the

mould

is unpainted sample to double check engineering and function of the final figure toy

7.

Mass production of the toy figures will be produced by using plastic material like Vinyl , PVC , ABS, PS , PP

etc

depended on toy design & function

8.

Make the paints according to painted prototype that serves as a paint guide , will work with a variety of oil and model paints with different application methods included washes, air brush , hand brush, Pad printing , All the colors can be matches PMS Color for the action figures

9.

All painted parts are assembled into complete figures, maybe adding plastic rivets or metal screw and in some cases , gluing and sonic welding parts together if needed .

10.

The newly finished figures & accessories are placed neatly into their customized packages and packed into cartons

Hot Searches