- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

JIA

-

Brand Name:

-

Leader

-

Dimension(L*W*H):

-

Custom Size

-

Weight:

-

0.35 KG

-

Working Temperature Range:

-

5 - 900 ℃

-

Heating medium:

-

Air/Water/Oil

-

Sheath material:

-

SUS304/316L/310S/Incoloy 800/Titanium

-

Insulation material:

-

High purity MGO powder(99.9%)

-

Lead connection method:

-

Internal / External

-

Product type:

-

High power density /Medium power density/Low power density availabe

-

Voltages available:

-

12V~410V

-

Wattage:

-

Customized

-

Certification:

-

CE, RoHS, ISO9001,ATEX

-

Application:

-

Molds/Pellet stoves/Barbecue Grills/Sealing equipments, etc.

Quick Details

-

Type:

-

Cartridge Heater

-

Power Source:

-

Electric

-

Voltage:

-

12v-415v

-

Place of Origin:

-

JIA

-

Brand Name:

-

Leader

-

Dimension(L*W*H):

-

Custom Size

-

Weight:

-

0.35 KG

-

Working Temperature Range:

-

5 - 900 ℃

-

Heating medium:

-

Air/Water/Oil

-

Sheath material:

-

SUS304/316L/310S/Incoloy 800/Titanium

-

Insulation material:

-

High purity MGO powder(99.9%)

-

Lead connection method:

-

Internal / External

-

Product type:

-

High power density /Medium power density/Low power density availabe

-

Voltages available:

-

12V~410V

-

Wattage:

-

Customized

-

Certification:

-

CE, RoHS, ISO9001,ATEX

-

Application:

-

Molds/Pellet stoves/Barbecue Grills/Sealing equipments, etc.

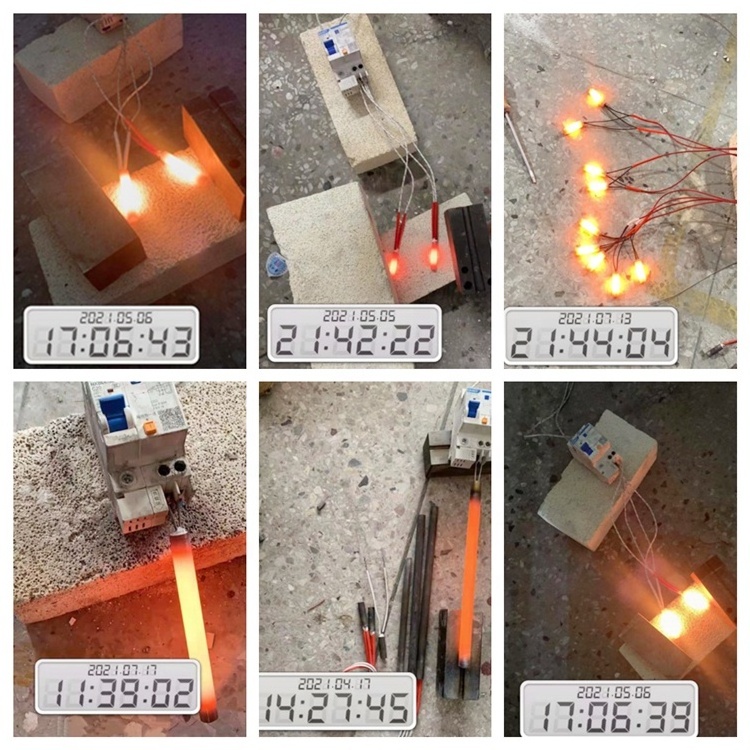

Product Description

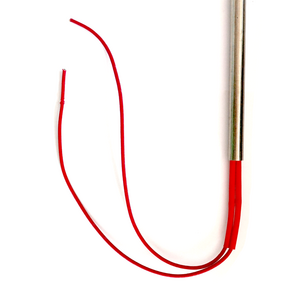

◆ Electric heater cartridge is a piece of equipment, made of MgO powder or MgO tube, ceramic cap, resistance wire(NiCr2080),High temperature leads, seamless stainless steel sheath(304,321,316,800,840)

◆ Usually in tube form,that is used in heating applications by way of insertion into metal blocks via a series of drilled holes.

◆ Cartridge heaters are manufactured in two basic forms - High powerdensity and Low and medium power density.

◆ High power density (heating surface power 10~25w/cm²), are widely used to heat Plastic injection moulds, Moulds, Platens and so on

◆ Low and medium power density (heating surface power5~11w/cm²), are more suitable for packing machinery, heat sealing, labelling machines and hot stamping applications.

◆ The high-quality stainless steel sheath provides long-lasting protection, even in the harshest industrial environments. Its max power density can reach up to 40w/cm², and its maximum operating temperature can over 800℃

◆ Usually in tube form,that is used in heating applications by way of insertion into metal blocks via a series of drilled holes.

◆ Cartridge heaters are manufactured in two basic forms - High powerdensity and Low and medium power density.

◆ High power density (heating surface power 10~25w/cm²), are widely used to heat Plastic injection moulds, Moulds, Platens and so on

◆ Low and medium power density (heating surface power5~11w/cm²), are more suitable for packing machinery, heat sealing, labelling machines and hot stamping applications.

◆ The high-quality stainless steel sheath provides long-lasting protection, even in the harshest industrial environments. Its max power density can reach up to 40w/cm², and its maximum operating temperature can over 800℃

Application

◆ Mold heating ◆ 3D Printer

◆ Hot melt heating ◆ Die casting molds

◆ Hot press rollers ◆ Extruder production line

◆ Semiconductor Industry ◆ Pharmaceutical machinery

◆ Textile industry-thermal cutting

◆ Packaging and sealing machinery

◆ Rubber molding equipment ◆ 3D Thermal bending

machinery

.......

Product Paramenters

|

Resistance wire

|

Cr20Ni80

|

|

Sheath Material

|

SS304/ 316L/ AISI321/ 310S/ Incoloy800/ Titanium Optional

|

|

Voltages available

|

12V/24V/36V/110V/220V/240V/380V/480V Available

|

|

Wattage Tolerance

|

±3%

|

|

Resistance tolerance

|

±3%

|

|

Length tolerance

|

± 2% or 3.2mm (1/8”)

|

|

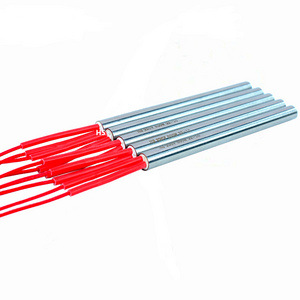

Diameter

|

From 2.0mm to 30mm

|

|

Diameter tolerance

|

+0.05mm -0.1mm (+.002" -.004")

|

|

Max operating temp

|

870ºC(1600F)

|

|

Standard Cold Zone

|

5-10mm

|

|

Thermocouple Location

|

Disc End, Sheath, Center of Heater

|

|

Thermocouple

|

Type J / K; PT 100 Available

|

Details Images

Ordering Guidance:

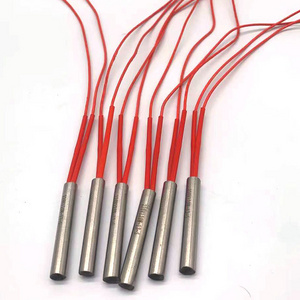

A. Tube diameter

B. Overall sheath length of Cartridge Heaters.

C. Lead length(Default 500mm).

E. Voltage requirement.

F. Wattage requirement.

G. Any other requirements (e.g.):

- Shape of Cartridge Heater and Thread size and diameter.

- Sheath material- Normal made of SS304.

- Lead material - Normal in silicone fiberglass lead.

- Sleeve material - Normal in fiberglass sleeving.

- lead connection method- Internal or External.

- Heating temperature and medium requirement.

Here 5 Different Cartridge Heater Structures Available

1. Cartridge Heater With Built-in Thermocouple

The thermocouple ("J" or "K" type) can be built into the end or middle of the cartridge heater, and it can be grounded or ungrounded. It is used to detect the temperature in the heating tube. It is very good by connecting with the controller. The temperature control effect.

2. Soaking Type Cartridge Heater

For the heating wire of the soaking type cartridge heater, the winding density at both ends is different from the middle. The higher winding density at both ends generates more heat than the middle, but the heat dissipation at both ends is faster than the middle, thus balancing Then, a heating section with uniform temperature is obtained.

3. Multi-heating Zone

Cartridge Heater

Heating wires with different winding densities are distributed in each area of the same heating tube, so that a heating tube can have multiple heating sections with different temperatures.

4. Designated Heating Zone Type Cartridge Heater

For some special scenes, there may be some areas and requirements that do not generate heat in the heating tube. This kind of scenario application can be realized by customizing the non-heating section

5. Auto-Power Adjustment Cartridge Heater

2 groups of independently controlled cartridge heaters or common electrode type multiple groups of controlled cartridge heaters. The heating system of the metal platform can use this type of heating tube in large quantities, and the corresponding heating section can be individually controlled according to the temperature of the heating plate to ensure the temperature uniformity of the heating platform.

Electric Cartridge Heater Customization Options

Honleader provide customization cartridge heater services to meet different applications.

Options including below details:

1. Built-in thermocouple - J or K type thermocouple sensor

2. Voltage (phase ) & power & watt density

3. Non-heating part length

4. Tube diameter & length

5. Sheath material

6. Lead/ lead protection

7. Seal material

8. Installation - flange/ locating ring/ screw

9. Finned

10. Inner structure - e.g. custom distributed wattage

Recommend Products

Hot Searches