- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1380*1200*2000mm

-

Weight:

-

2000 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

Customized, 200KW

-

Product name:

-

Tomato concentrate production line

-

Evaporation type:

-

forced circulation evaporator

-

Material:

-

SUS304

-

Automation:

-

Automatic control

-

Final product:

-

Jam

-

Color:

-

Silver

-

Package:

-

Wooden Case

-

Heating source:

-

Electricity

-

Temperature Range:

-

18-80

Quick Details

-

Machinery Capacity:

-

50 pieces

-

Brand Name:

-

BEYOND

-

Year:

-

2022

-

Dimension(L*W*H):

-

1380*1200*2000mm

-

Weight:

-

2000 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

Customized, 200KW

-

Product name:

-

Tomato concentrate production line

-

Evaporation type:

-

forced circulation evaporator

-

Material:

-

SUS304

-

Automation:

-

Automatic control

-

Final product:

-

Jam

-

Color:

-

Silver

-

Package:

-

Wooden Case

-

Heating source:

-

Electricity

-

Temperature Range:

-

18-80

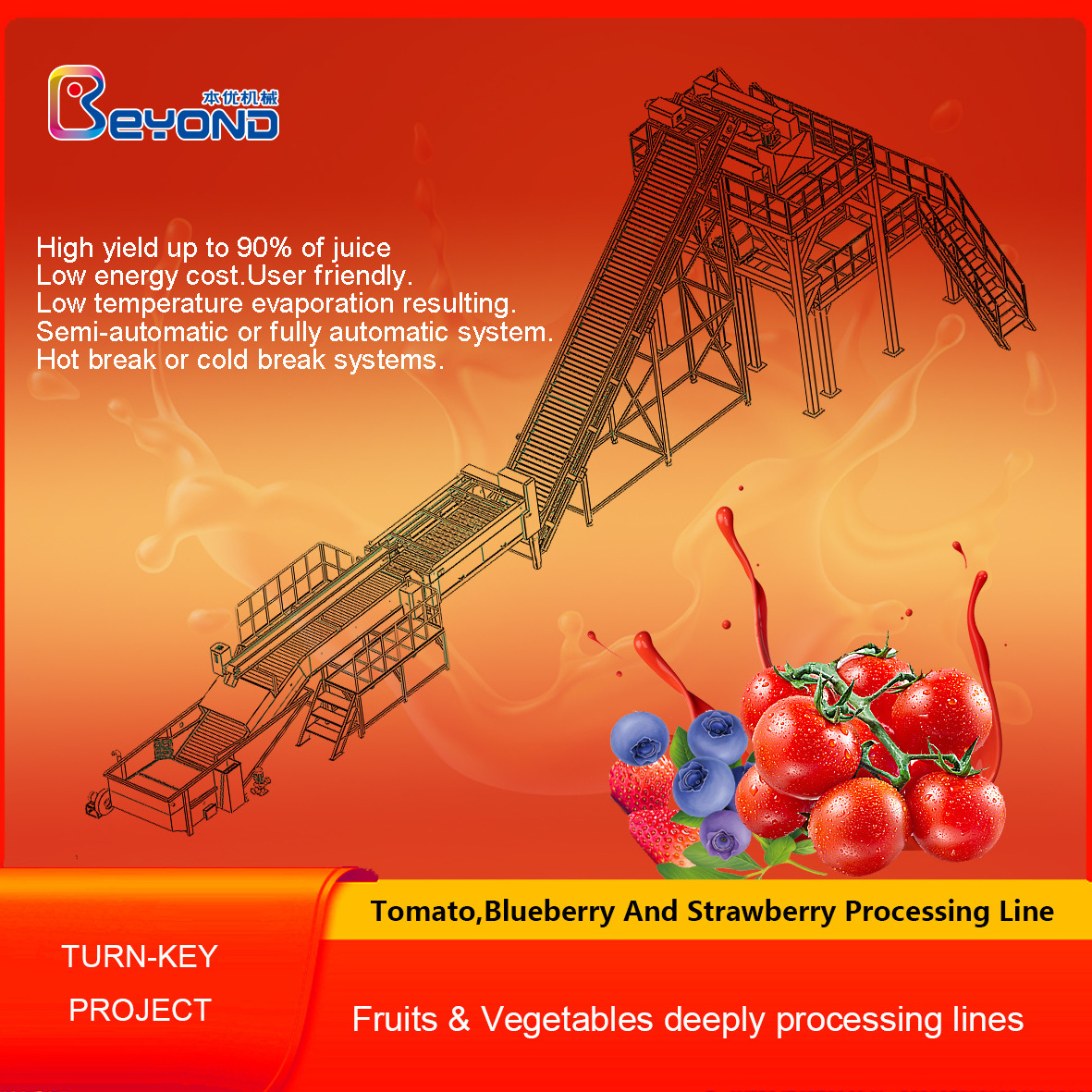

Fruit juicer production line processing machine full automatic tomato concentrate production line

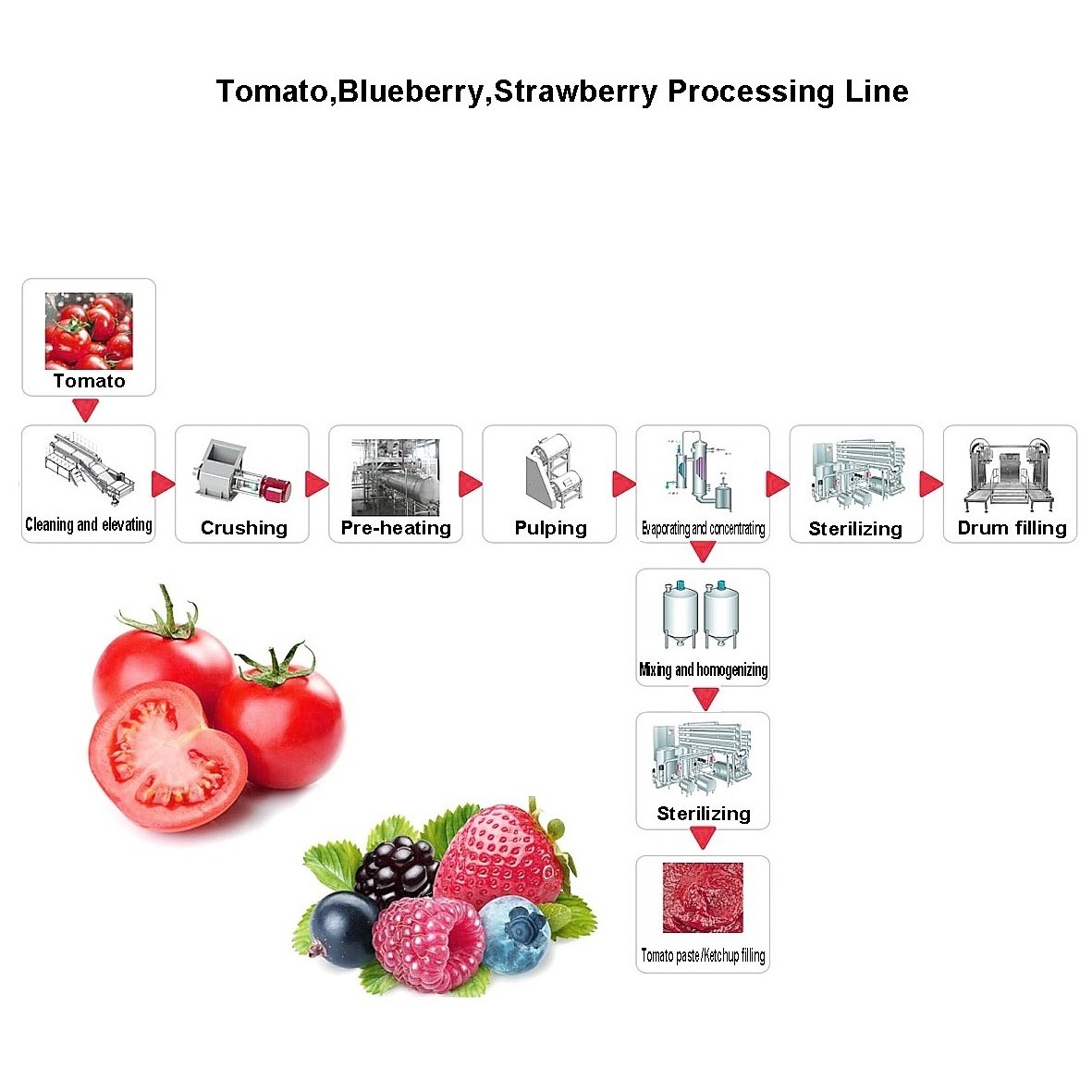

Shanghai beyond offers complete set of tomato ketchup production machinery on turnkey basis to produce the following end products from tomatoes.

- Tomato Puree from tomato processing line

- Tomato Paste from tomato paste production line

- Tomato Ketchup/Sauces from tomato ketchup puree plant

- Tomato Juices from tomato juice processing plant

Packing lines can be offered depending upon the requirement like Product in glass bottles, Cans, Drums, etc. Manufacturing process involves most modern technology of vacuum evaporation using forced circulation evaporators/scrapped surface evaporators. Evaporation plants are versatile in nature and can concentrate other juices also.

SALIENT FEATURES:

- High yield up to 90% of juice

- Low energy cost.

- Low temperature evaporation resulting improved quality of products.

- User friendly.

- Semi-automatic as well as fully automatic system available.

- Both hot break and cold break systems available.

|

Raw material

|

Fresh tomato(about 4.5brix)

|

|

End product

|

Tomato paste (28~30brix)

|

|

Processing capacity

|

6 tons per hour based on fresh tomato

|

|

Daily Output

|

17~20 tons per day(24hours)

|

|

Packaging

|

Aspect drum(5~220L)

|

|

Total power

|

220KW

|

|

Steam Consumption

|

3.5-4.2 t/h

|

|

Water Consumption

|

15-20 t/h

|

|

Cooling circulating

water consumption |

180-250 t/h( inlet temperature: 32℃;outlet temperature:38℃) |

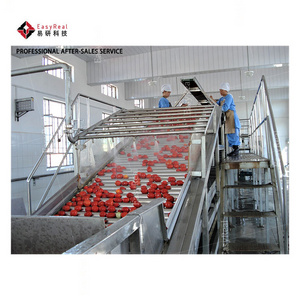

Project Photos Show:

Filling and sealing of tomato juice

The containers used for tomato juice are metal cans,glass bottles or PET bottles.The pre-sterilized tomato juice is filled into a clean container.In order to prevent oxidation,it is necessary to quickly cool the sterilized tomato juice to 85-89℃ and fill it into the container immediately.To prevent oxidation of the product,this filling method is called hot filling.It should be sealed immediately after filling.

Secondary pasteurization and packing of the tomato juice

After the filling is completed,for the sake of safety,the tomato juice needs to be sterilized twice,and the filled container is transported to the pasteurization tunnel or retort for secondary sterilization.The sterilization process is 90-95℃ for 15-20min.Then use cooling water to quickly cool the temperature of tomato juice to below 35℃ for subsequent packaging.

We offer turnkey projects for tomato processing plants,include process concentrated tomato paste,tomato puree,tomato sauce,ketcup,tomato powder and other tomato products.

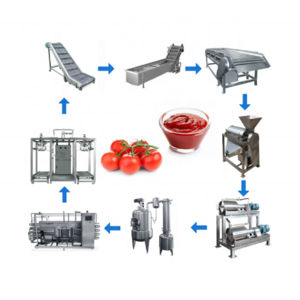

Workflow diagram