- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

STR

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

10700x930x1290mm

-

Weight (KG):

-

254

-

Power (kW):

-

1

-

Product name:

-

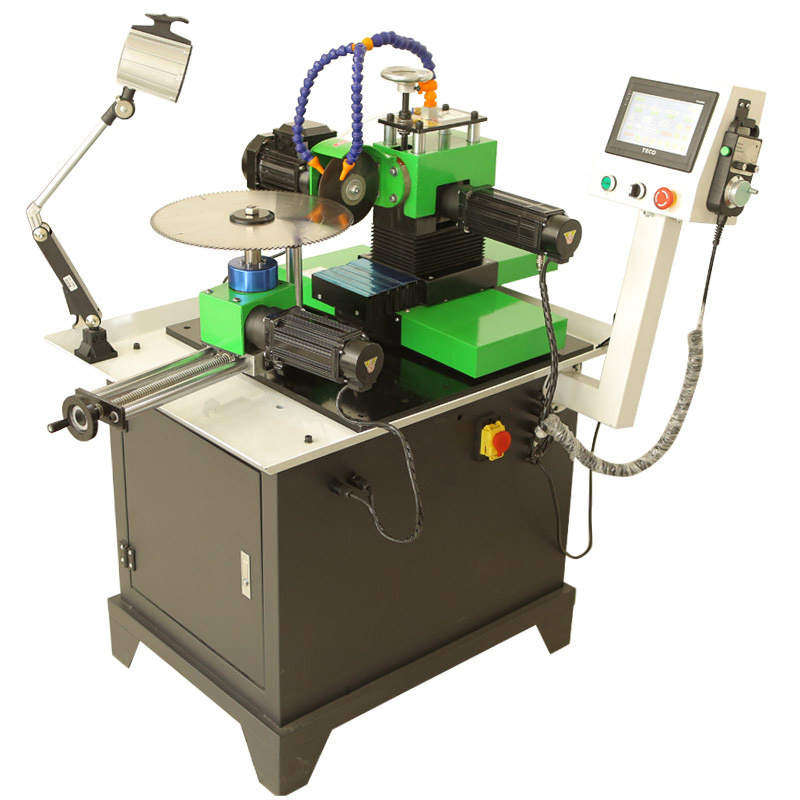

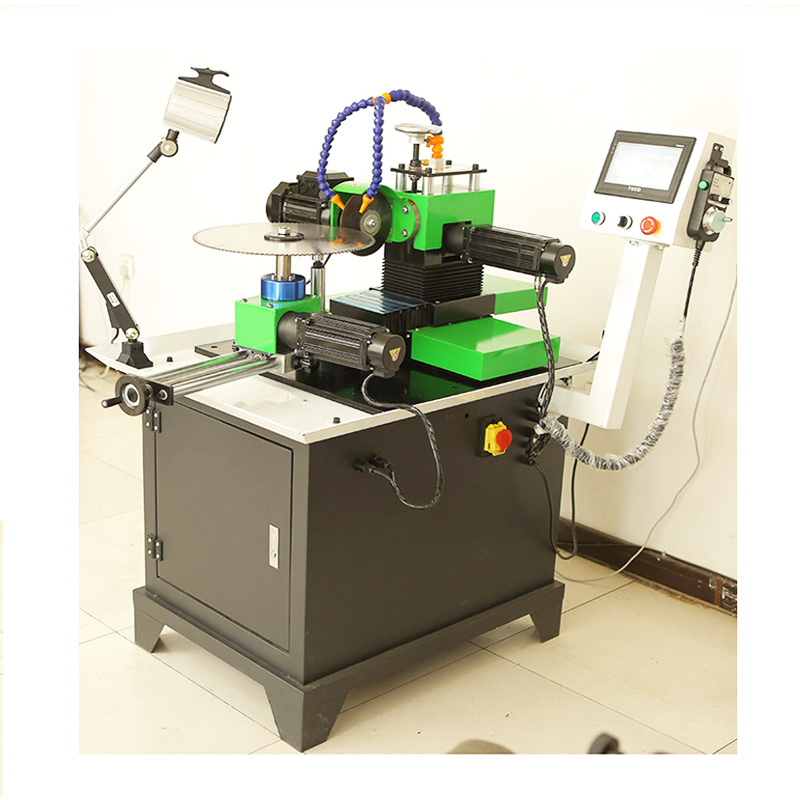

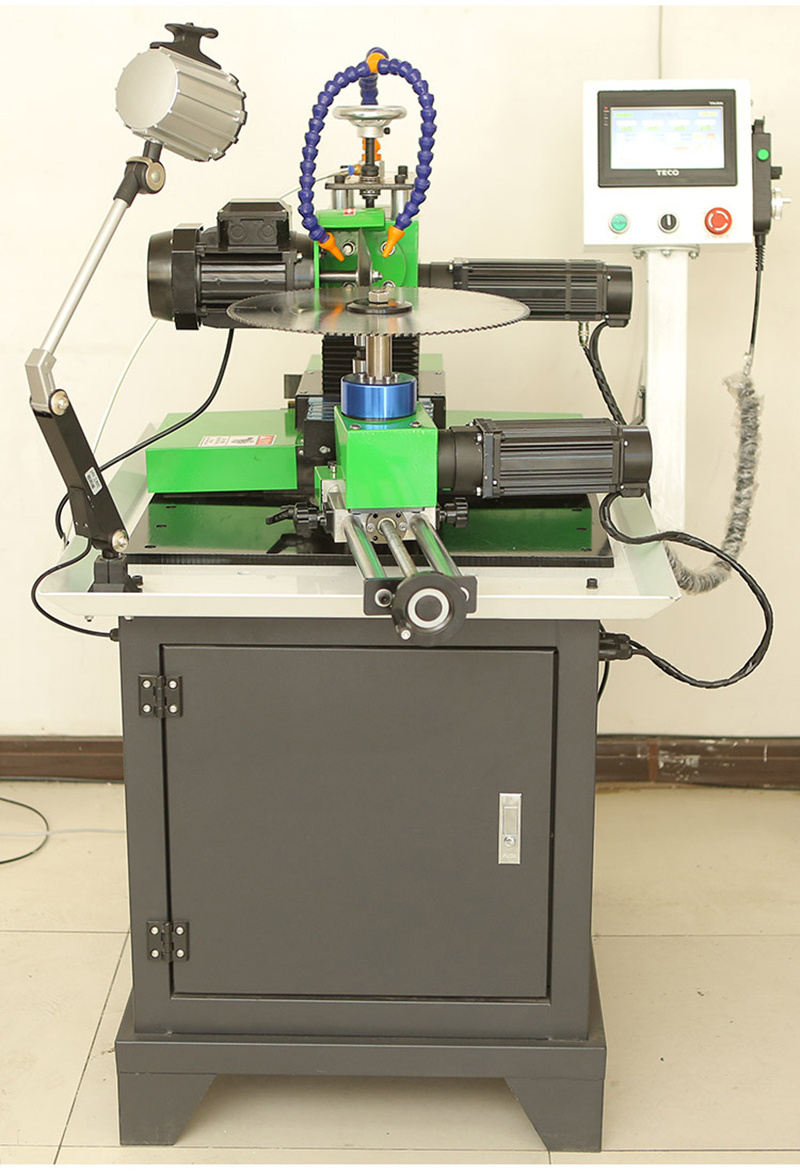

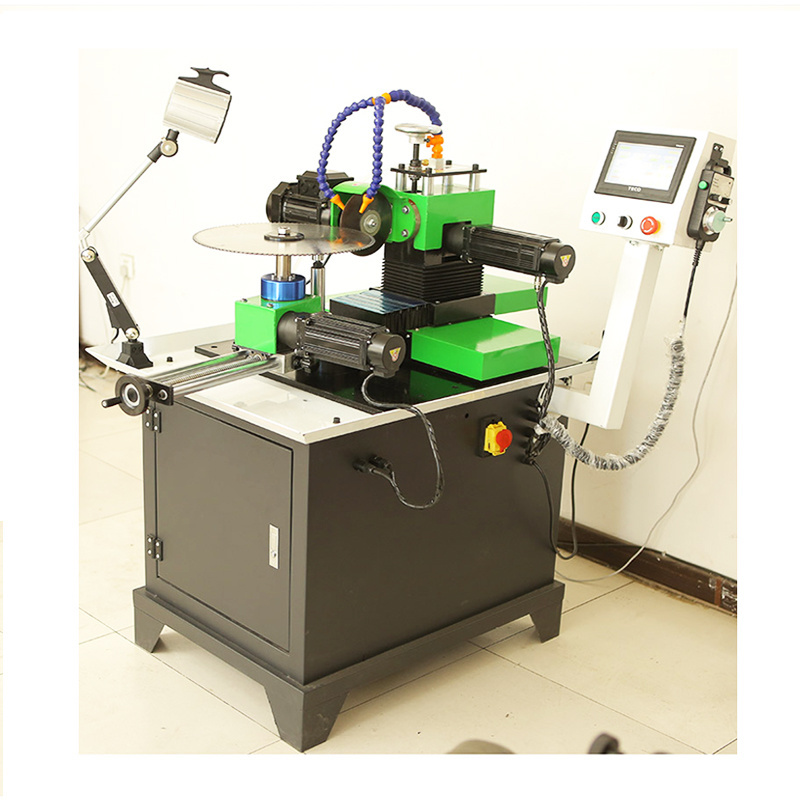

saw blade sharpening machine

-

Application:

-

Grinding/Sharpening Sawtooth

-

Machine Type:

-

Automatic Surface Grinder Machine

-

Material:

-

Cast Steel

-

Grinding Dimension:

-

100-800mm

-

Alloy Grinding Wheel Size:

-

150x32x10mm

-

Grinding Wheel Speed:

-

2850r/min

-

Maximum grinding length:

-

45mm

Quick Details

-

Wheel Size(mm):

-

150x32x10mm

-

Year:

-

2021

-

Place of Origin:

-

China

-

Brand Name:

-

STR

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

10700x930x1290mm

-

Weight (KG):

-

254

-

Power (kW):

-

1

-

Product name:

-

saw blade sharpening machine

-

Application:

-

Grinding/Sharpening Sawtooth

-

Machine Type:

-

Automatic Surface Grinder Machine

-

Material:

-

Cast Steel

-

Grinding Dimension:

-

100-800mm

-

Alloy Grinding Wheel Size:

-

150x32x10mm

-

Grinding Wheel Speed:

-

2850r/min

-

Maximum grinding length:

-

45mm

Recommend Products

Product Description

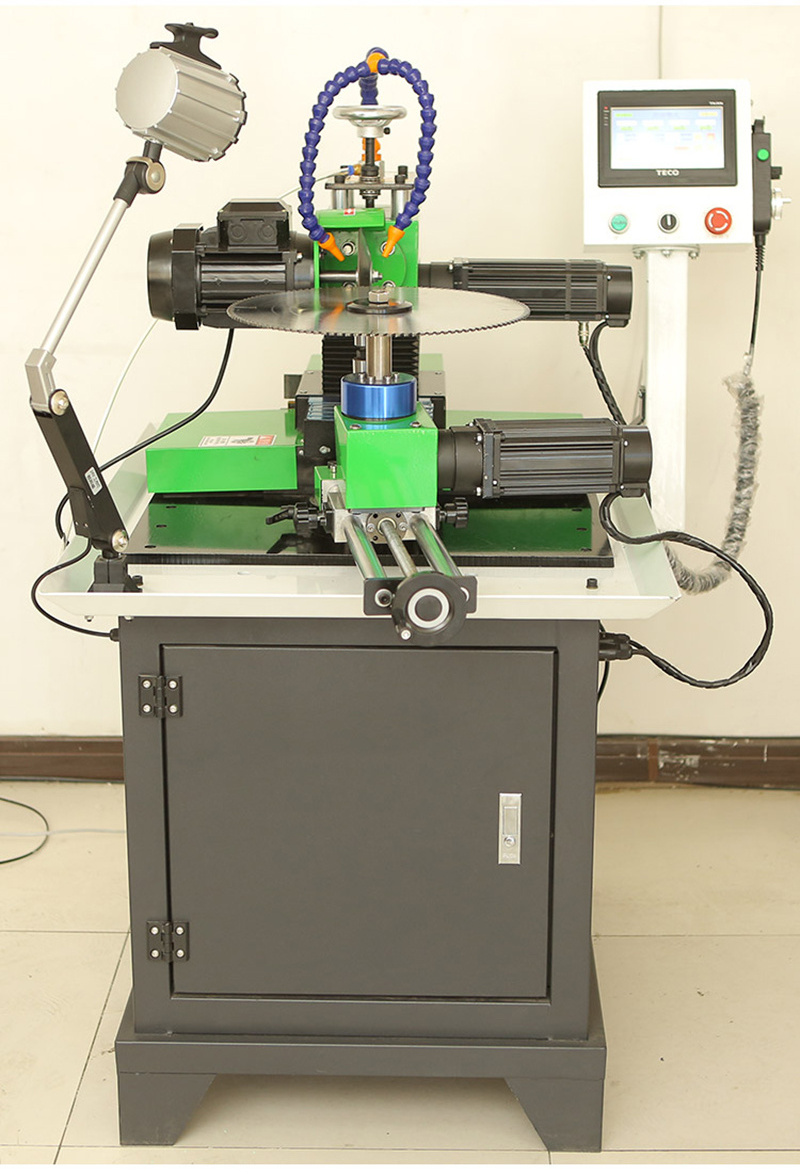

Title: Woodworking saw blade grinder: key equipment to improve wood processing efficiency

In the woodworking industry, saw blades are essential tools. However, over time, saw blades gradually wear out, resulting in a decrease in cutting efficiency and quality. In order to solve this problem, woodworking saw blade grinding machines came into being. This is a piece of equipment specifically designed to repair and re-sharpen saw blades, significantly improving the efficiency and quality of wood processing.

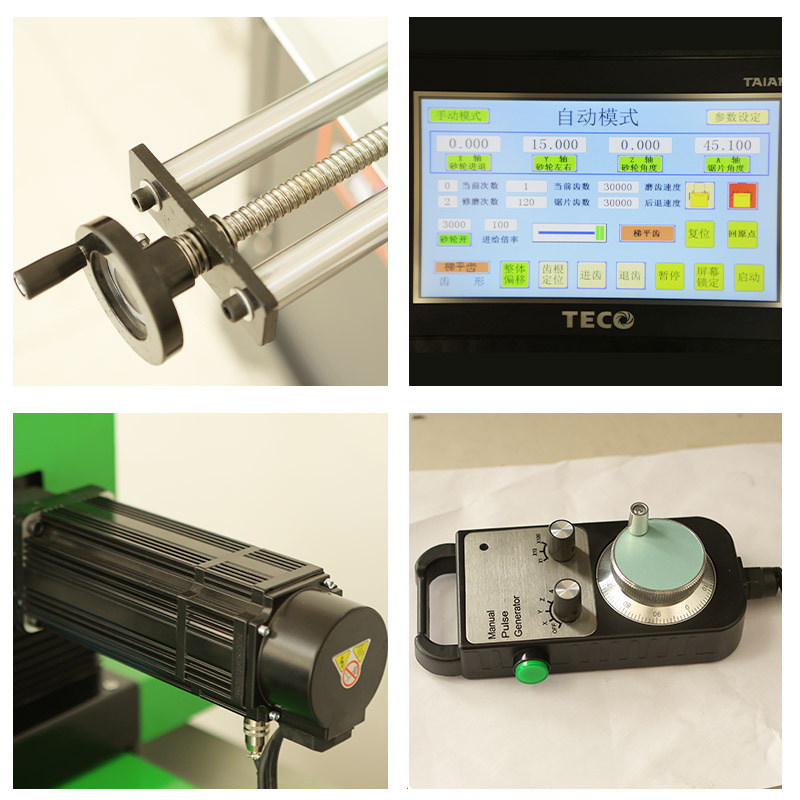

1. Working principle of woodworking saw blade grinding machine

The working principle of a woodworking saw blade grinder is relatively simple. It uses a high-speed rotating grinding wheel to grind the saw blade to remove the worn parts of the saw teeth and re-form a sharp cutting edge. During this process, the gear grinding machine automatically adjusts the feed speed and angle of the grinding wheel according to preset parameters to ensure grinding quality and consistency.

2. Advantages of woodworking saw blade grinding machine

1. Increase the service life of the saw blade: Regular grinding of the teeth can extend the service life of the saw blade, reduce the frequency of saw blade replacement, and reduce production costs.

2. Improve cutting efficiency: The ground saw blade has a sharper cutting edge, which can cut wood faster and improve production efficiency.

3. Improve wood quality: The ground saw blade can more accurately control the cutting depth and width of wood, reduce wood waste, and improve the processing quality of wood.

4. Easy to operate: Woodworking saw blade grinding machines usually have a user-friendly interface, the operation is simple and easy to understand, and no professional skills are required.

3. Application scenarios of woodworking saw blade grinding machine

Woodworking saw blade grinding machines are widely used in various areas of the wood processing industry, including:

1. Furniture manufacturing: The furniture production process requires a large amount of wood cutting and processing. Using a gear grinder can increase the life of the saw blade and cutting efficiency, and improve the quality of furniture production.

2. Wood floor production: The wood floor production process requires fine cutting and processing of wood. Using a gear grinder can improve the life of the saw blade and cutting accuracy, and ensure the quality of the wood floor.

3. Architectural decoration: The architectural decoration industry requires a large amount of wood cutting and processing. Using a gear grinder can improve the life of the saw blade and cutting efficiency, and improve the construction progress of the decoration project.

4. Conclusion

In short, woodworking saw blade grinding machine is an indispensable piece of equipment in the wood processing industry. It can significantly improve the service life and cutting efficiency of the saw blade, improve the processing quality of wood, and reduce production costs. For anyone involved in the woodworking industry, having a good woodworking saw blade grinder is very important.

Specification

|

Model

|

4Z-80 CNC saw baldes grinding machine

|

|

Grinding saw size

|

100-800mm

|

|

Feeding teeth distance

|

5-45mm

|

|

Feeding teeth speed

|

0-100 teeth/min

|

|

grinding wheels speed

|

2850r/min

|

|

Grinding wheels size

|

150x32x10mm

|

|

Grinding wheels motor

|

1000W

|

|

Z axis motor

|

1000W

|

|

X axis motor

|

100W

|

|

Y axis motor

|

100W

|

|

A axis motor

|

1000W

|

|

Weight

|

254kgs

|

|

size

|

107x93x129cm

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

1.What is your MOQ?

Our MOQ is usually only SET.

2.What is your delievery time?

The time of delievery is around 10-45days.

3.What is the shipping port?

We ship the goods via Xiamen or Shanghai port.

4.What is your payment terms?

We accept 50% T/T in advance,50% in the period of shipment or 100% L/C.

5.How should I contact you?

You can contact us with Trade Manager or send us an email by click Contact Supplier bottom.

6.What is the location of your company?

Our company is located in the Xiamen Fujian Province,China.

If you would like to have a visit, you are much welcome.

7.How about the samples?

We could send you the samples ,most samples are free to send to most places in China.If sent to other countries,transport fee

shoule be paid by you.

Our MOQ is usually only SET.

2.What is your delievery time?

The time of delievery is around 10-45days.

3.What is the shipping port?

We ship the goods via Xiamen or Shanghai port.

4.What is your payment terms?

We accept 50% T/T in advance,50% in the period of shipment or 100% L/C.

5.How should I contact you?

You can contact us with Trade Manager or send us an email by click Contact Supplier bottom.

6.What is the location of your company?

Our company is located in the Xiamen Fujian Province,China.

If you would like to have a visit, you are much welcome.

7.How about the samples?

We could send you the samples ,most samples are free to send to most places in China.If sent to other countries,transport fee

shoule be paid by you.

Hot Searches