- Product Details

- {{item.text}}

Quick Details

-

Heating Power (kW):

-

100 kW

-

Production Speed(times/h):

-

1200

-

Power Supply:

-

3 phase 380V 50Hz or others

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HAIYUAN

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

25x6x3m

-

Weight (T):

-

18 T

-

Name:

-

POLYSTYRENE STYROFOAM WHITE FOOD CONTAINER DISH TRAY MAKING MACHINE

-

forming machine eficiency:

-

3-4 s/Die

-

sheet thickness:

-

0.8--5mm

-

Raw material:

-

GPPS Hips Polystyrene Talc Powder

-

Usage:

-

to make sheet and food container / food box / absorbent tray

-

forming machine:

-

fully automatic vacuum forming machine with robot arms

-

Ellie's whats:

-

008613780912769

-

the complete line include three machine:

-

sheet extruder+forming machine +recycling machine

-

Keyword:

-

PS FOAM BOX PLATE MACHINE

Quick Details

-

Max.Forming Height(mm):

-

100 mm

-

Forming Width (mm):

-

1100 mm

-

Forming Length (mm):

-

1400 mm

-

Heating Power (kW):

-

100 kW

-

Production Speed(times/h):

-

1200

-

Power Supply:

-

3 phase 380V 50Hz or others

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HAIYUAN

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

25x6x3m

-

Weight (T):

-

18 T

-

Name:

-

POLYSTYRENE STYROFOAM WHITE FOOD CONTAINER DISH TRAY MAKING MACHINE

-

forming machine eficiency:

-

3-4 s/Die

-

sheet thickness:

-

0.8--5mm

-

Raw material:

-

GPPS Hips Polystyrene Talc Powder

-

Usage:

-

to make sheet and food container / food box / absorbent tray

-

forming machine:

-

fully automatic vacuum forming machine with robot arms

-

Ellie's whats:

-

008613780912769

-

the complete line include three machine:

-

sheet extruder+forming machine +recycling machine

-

Keyword:

-

PS FOAM BOX PLATE MACHINE

Products Description

PS FOAM BOX PLATE MACHINE / AUTOMATIC POLYSTYRENE STYROFOAM WHITE DISPOSABLE FOOD CONTAINER DISH TRAY MAKING MACHINE

If you ask for ROI and factory set-up design CAD drawing , please send hi to Ellie's WhatsApp 008613780912769

If you ask for ROI and factory set-up design CAD drawing , please send hi to Ellie's WhatsApp 008613780912769

The whole complete production line includes :

* PS foam sheet extrusion machine + * vacuum forming machine + * recycling machine

1.

PS Foam Sheet Extrusion Line :

PS foam sheet machine adopts Gentian type double-stage series high foam technology.

The raw material is general polystyrene granule. In the extruding process, vesicant is injected at high pressure. After extruding, foaming cooling, shaping and hauling off, it is winding to finished ps foam sheet rolls .After vacuum forming system, the finished PS foaming sheet can be made into variety of packaging vessels such as fast food box,

aquatic plate,

supermarket tray,

cake tray

,KT board, instant noodle bowl,

foam tray etc. It is widely used in the packing of food,

fruit advertising ,industrial products and so on.

This equipment adopts high speed non-stop hydraulic filter changer and PLC controller.

|

1. PS foam sheet extrusion machine parameter

|

kg/h

|

HY-75/90

|

HY-105/120

|

HY-110/130

|

HY-135/150

|

||||

|

capacity

|

kg/h

|

80-100

|

200-240

|

230-260

|

280-360

|

||||

|

sheet thickness

|

mm

|

1-4

|

1-4

|

1.5-5

|

2-5

|

||||

|

sheet width

|

mm

|

640-1080

|

|

800-1080

|

900-1080

|

||||

|

foaming rate

|

/

|

10-22

|

|

|

|

||||

|

cooling method

|

water & wind cooling

|

|

|

|

|

||||

|

butane gas pressure

|

Mpa

|

0.9-1.2

|

|

|

|

||||

|

installation power

|

KW

|

160

|

200

|

260

|

320

|

||||

|

installation dimension

|

m

|

24x6x3

|

30x6x3

|

32x6x3

|

35x8x3

|

||||

|

power supply

|

3 phase 380V 50Hz / 220V 60Hz / can be customized

|

|

|

|

|

||||

PS fast food box vacuum forming machine is an all-powerful thermal forming machine with integration of vacuum forming Press forming and synthetical forming.

It can be used for processing many kinds of plastic sheet.

The machine adopts digital system,

fully automatic PLC mechanical and electronic integration control,

touch screen to control the working programme .It is easy to operate and of high efficiency.

It features reliable stability,

large forming area,

fast speed ,highly automation and economic on manpower.

|

2. vacuum forming machine parameter

|

|

HY-1100x1100

|

HY-1100x1250

|

HY-1100x1400

|

|||

|

forming area

|

mm

|

1100x1100

|

1100x1250

|

1100x1400

|

|||

|

cutting off height

|

mm

|

160

|

160

|

160

|

|||

|

production effiency

|

seconds/die

|

3-4

|

|

|

|||

|

installation dimension

|

m

|

19x6x3

|

21x6x3

|

24x6x3

|

|||

|

installation power

|

KW

|

150

|

160

|

180

|

|||

|

power supply

|

3 phase 380V 50Hz / 220V 60Hz / can be customized

|

|

|

|

|||

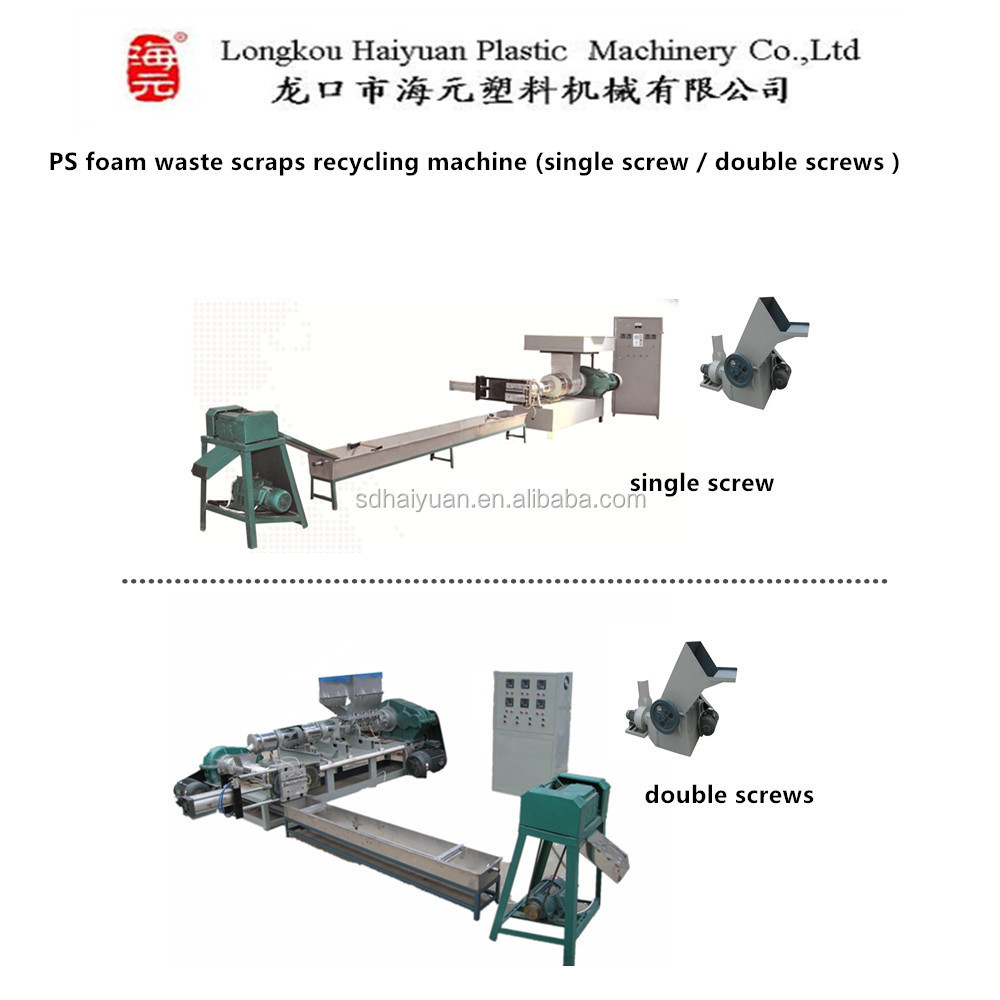

This machine is mainly used to recycle the high foam polystyrene and high foam polyethylene products.

It is the ideal equipment to recycle the waste materials.

This equipment features compact structure and easy operation.

The high foam plastic can be directly used to make granulation without comminuting.

At present ,it is the ideal energy-saving equipment.

|

3. Recycling machine parameter

|

model HY-125

|

|

|

||

|

screw diameter

|

125mm

|

|

|

||

|

installation power

|

30KW

|

|

|

||

|

installation dimension

|

8x3x2m

|

|

|

||

|

weight

|

1.5Ton

|

|

|

||

|

power supply

|

3 phase 380V 50Hz / 220V 60Hz /

can be customized

|

|

|

||

# New Arrivals #

PS foam absorbent tray making machine

this machine can produce normal PS foam disposable food box / plate / bowl / dish / egg tray / wine tray / false ceiling tiles / food container ; also can produce PS foam absorbent meat tray , the absorbent tray with holes can absorb fresh meat or chicken blood very fast .

Certifications

Finished Products

PS foam disposable food container making machine

polystyrene foam take away food box plate machine

PS foam fast food box production machine

polystyrene PS foam egg tray machine

PS foam bowl machine

PS foam absorbent tray production line

PS foam food plate bowl dish tray box container production machine

PS foam false ceiling tiles making machine

PS foam water suction tray machine

PS foam sheet extrusion machine

PS foam scraps recycling machine

PS foam sheet laminating / printing machine

Our Service

Other PS Machine

contact Ellie

Hot Searches