- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

customizable

-

Place of Origin:

-

Gansu, China

-

Brand Name:

-

SUPERALLOY

-

Model Number:

-

C17200

-

Application:

-

connectors, switches, and relays.

-

Width:

-

customizable

-

Grade:

-

Beryllium copper series alloy

-

Product name:

-

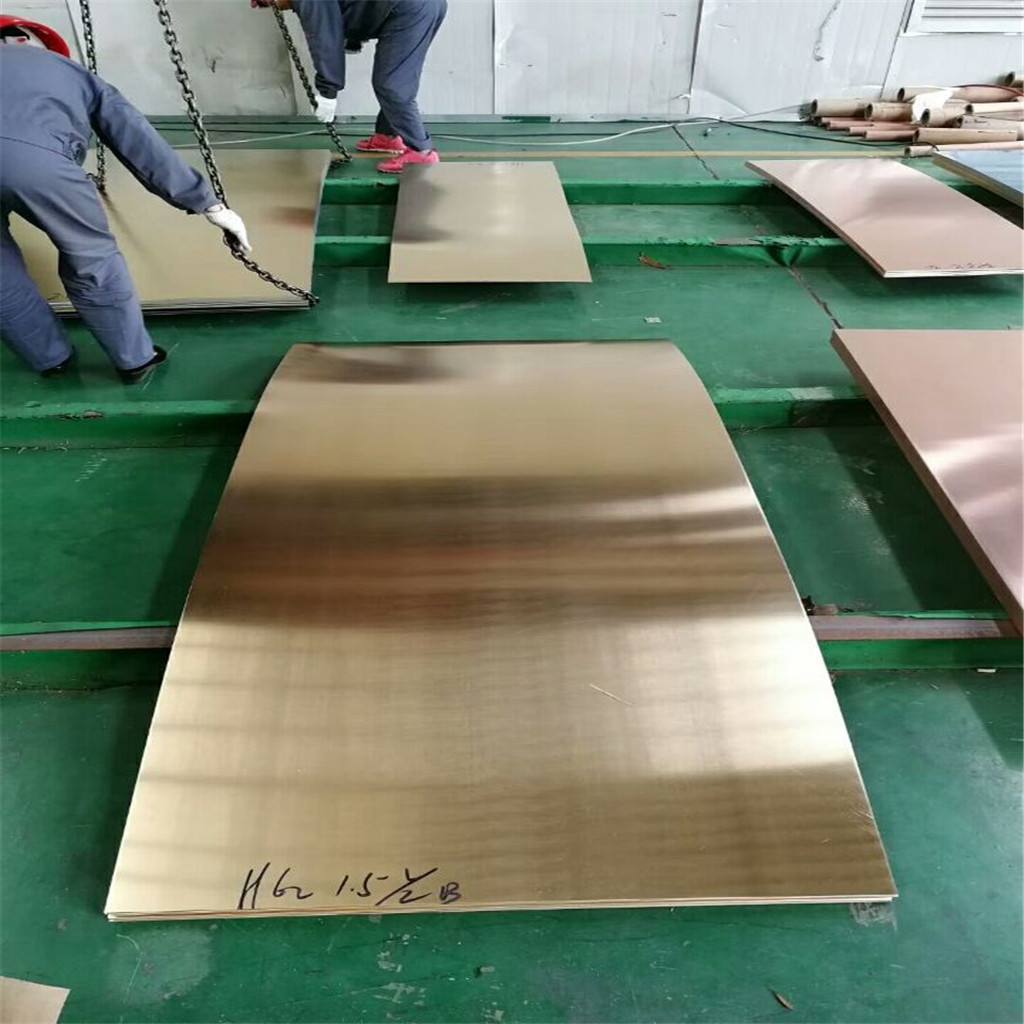

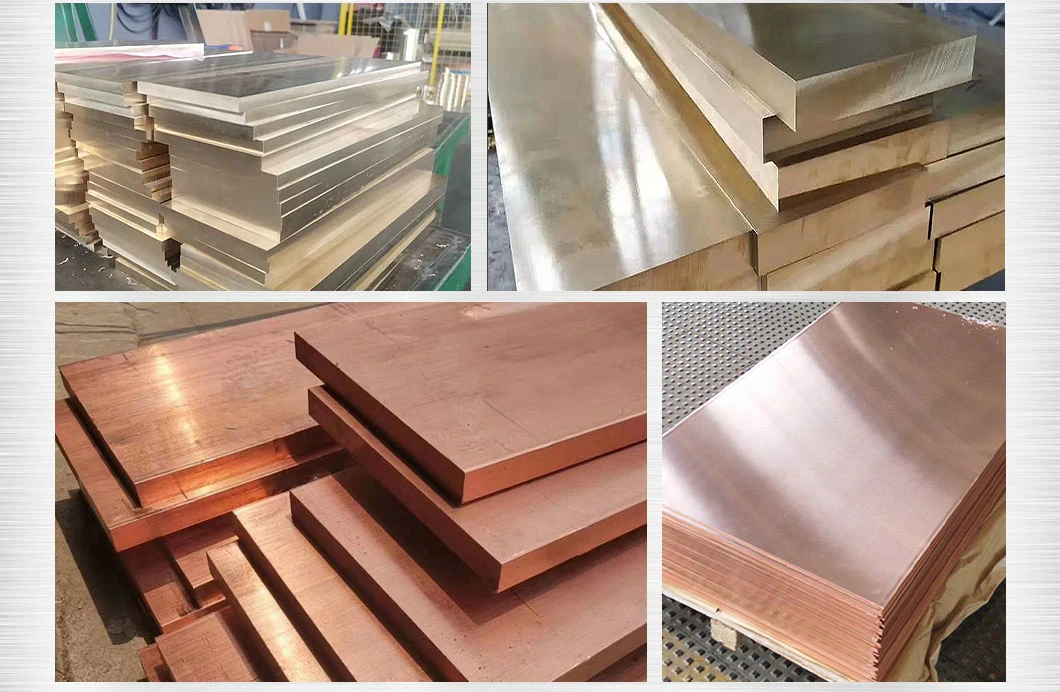

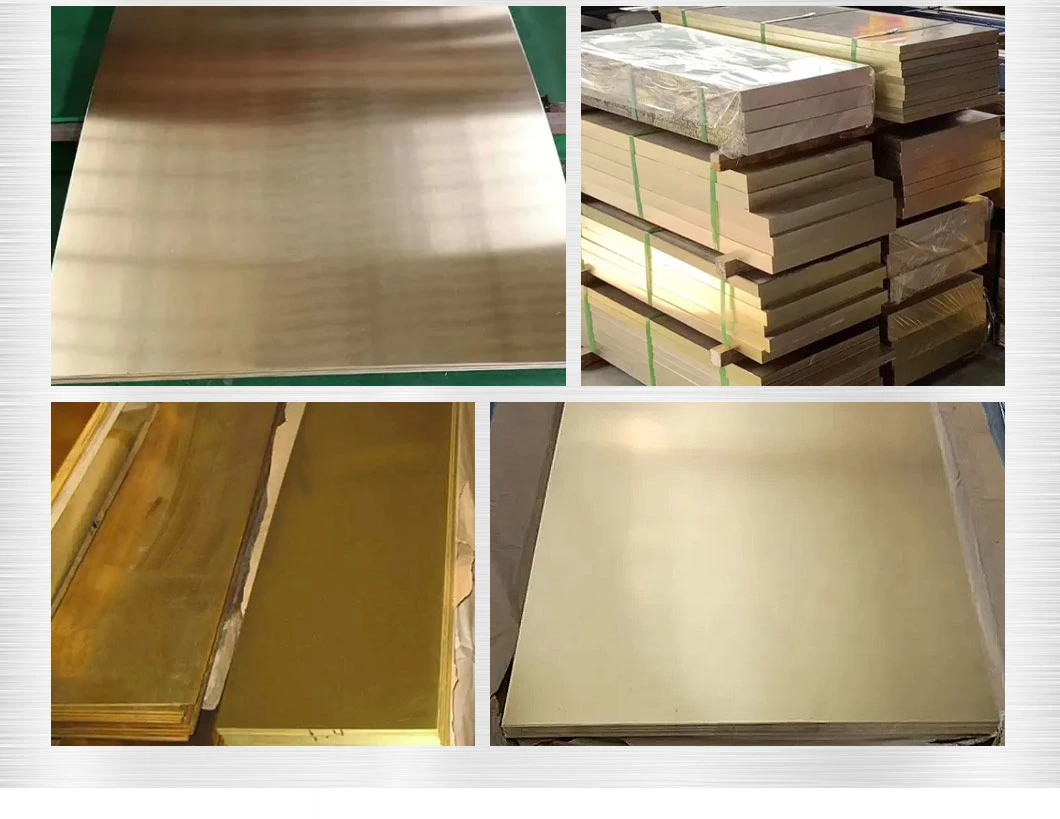

Beryllium copper alloy Plate

-

Material:

-

High Purity 99% Copper

-

Keyword:

-

C17200 Copper Plate/ Copper Sheet

-

Standard:

-

JIS ASTM DIN EN ISO

-

Surface:

-

Brush

-

Length:

-

Customer's Demands

-

Package:

-

Standard Seaworthy Package

-

PRICE TERM:

-

CIF CFR FOB Ex-Work

-

Certification:

-

ISO9001:2015

-

Feature:

-

High Tensile Strength

Quick Details

-

Cu (Min):

-

99.5%

-

Alloy Or Not:

-

Is Alloy

-

Ultimate Strength (≥ MPa):

-

1035

-

Elongation (≥ %):

-

customizable

-

Place of Origin:

-

Gansu, China

-

Brand Name:

-

SUPERALLOY

-

Model Number:

-

C17200

-

Application:

-

connectors, switches, and relays.

-

Width:

-

customizable

-

Grade:

-

Beryllium copper series alloy

-

Product name:

-

Beryllium copper alloy Plate

-

Material:

-

High Purity 99% Copper

-

Keyword:

-

C17200 Copper Plate/ Copper Sheet

-

Standard:

-

JIS ASTM DIN EN ISO

-

Surface:

-

Brush

-

Length:

-

Customer's Demands

-

Package:

-

Standard Seaworthy Package

-

PRICE TERM:

-

CIF CFR FOB Ex-Work

-

Certification:

-

ISO9001:2015

-

Feature:

-

High Tensile Strength

Beryllium copper series alloy

Beryllium copper series alloys are made by adding trace elements such as beryllium, cobalt, and nickel to copper, which can greatly improve the overall performance of the material, It is the "king of elasticity" in copper alloys, and a copper alloy that combines strength, conductivity,

processability, fatigue resistance, heat resistance, and corrosion resistance. It is widely used in electronic components such as connectors, switches, and relays. Beryllium copper produced by National Industry contains various alloys and specifications, and can provide strip, plate, bar, wire, and mold materials.

processability, fatigue resistance, heat resistance, and corrosion resistance. It is widely used in electronic components such as connectors, switches, and relays. Beryllium copper produced by National Industry contains various alloys and specifications, and can provide strip, plate, bar, wire, and mold materials.

|

Chemical composition (wt%)

|

C17200

|

Chemical composition (wt%)

|

C17500

|

Physical property

|

|

C17200

|

C17500

|

|

|

Cu

|

/

|

Cu

|

/

|

Conductivity

|

%IACS(20℃)

|

22-28

|

≥75

|

|

|

Be

|

1.8-2.0

|

Be

|

0.4-0.7

|

Tensile strength

|

Mpa

|

1105

|

≥680

|

|

|

Ni

|

/

|

Si

|

0.2

|

Yield strength

|

(0.2%)Mpa

|

1035

|

≥550

|

|

|

Co

|

|

Fe

|

0.1

|

Specific heat

|

J/(kg·K)(20°℃)

|

419

|

420

|

|

|

Ni+Co

|

≥0.20

|

Al

|

0.2

|

Melting temperature

|

℃

|

870

|

1070

|

|

|

Ni+Co+Fe

|

≤0.6

|

Sn

|

/

|

Thermal conductivity

|

W/(m·K)(20℃)

|

90-120

|

180-220

|

|

|

Cu+Be+Ni+Co+Fe

|

≥99.5

|

Co

|

2.4-2.7

|

Modulus of elasticity

|

K*Kg/mm²

|

13.4

|

14.1

|

|

|

Si+Fe+Al+Pb

|

|

The sum of the elements listed in Cu+

|

99.5

|

Thermal expansion coefficient

|

a/K(20-300°℃)

|

17.0×10-6

|

18×10-6

|

|

Ultra High Strength Titanium Bronze - C19900

The C19900 series alloy adds titanium and other trace elements such as iron, lanthanum, and yttrium to copper to enhance its performance. Compared with ordinary precipitation hardened copper alloys, it enhances the strength and hardness of the material, improves the formability of the product, and has high strength, high hardness, high elongation, excellent formability, and good stress relaxation at high

temperatures. Widely used in electronic equipment, domestic military products, and also for some mold materials

temperatures. Widely used in electronic equipment, domestic military products, and also for some mold materials

|

Element

|

Chemical composition(wt%)

|

|

|

|

|

||||

|

|

Ti

|

Fe

|

Y

|

La

|

Cu+Ti+Fe+Y+La

|

||||

|

Content

|

2.9-3.4

|

0.17-0.23

|

0-0.06

|

0-0.06

|

≥99.5

|

||||

|

Conductivity (20 ℃)

|

Specific resistance (20 ℃)

|

Thermal conductivity

|

Thermal expansion coefficient

|

Young's modulus

|

|

Density

|

|

|

|

|

|

|

LD GPa

|

TD GPa

|

|

|

|

10-14%

IACS |

132-172

n2.m |

66.8

W/mk |

18.0A10-6/K

(20-200°℃) |

125

|

135

|

8.70

g/cm3 |

|

|

|

|

|

|

|

|

|

|

Hot Searches