- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3600*1850*2600 mm

-

Weight:

-

4500 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Coal Washing Plant Tantalum Niobium Jig Concentrator

-

Capacity:

-

10-15 t/h

-

Feeding size:

-

30 mm

-

Water feeding:

-

1-3 m3/t

-

Color:

-

Customized Painted

-

Engine:

-

Motor or Diesel Engine

-

Material:

-

Carbon Steel

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Feature:

-

Simple Operation

-

Keywords:

-

Jigging machine

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

China

-

Brand Name:

-

Yuxiang

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3600*1850*2600 mm

-

Weight:

-

4500 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Coal Washing Plant Tantalum Niobium Jig Concentrator

-

Capacity:

-

10-15 t/h

-

Feeding size:

-

30 mm

-

Water feeding:

-

1-3 m3/t

-

Color:

-

Customized Painted

-

Engine:

-

Motor or Diesel Engine

-

Material:

-

Carbon Steel

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Feature:

-

Simple Operation

-

Keywords:

-

Jigging machine

Mining Gravity Jig Separating/Separator Machine Equipment Coal Washing Plant Tantalum Niobium Jig Concentrator

Product Description

Jigging machine is

one of the relative new methods for gravity concentration. It

is screen fixed type machine that realizes the separation of light and heavy mineral by the different sedimentation speed in vertical alternating water flow, it mainly used to handle placer gold,tungsten, tin, hematite and beach placer and other minerals

due to its high processing capacity, large range of separation size and simplicity of operation and maintenance.

.

1. Big capacity, less land occupation, wide recover range on size

2. High concentrating ratio and high recovery

2. High concentrating ratio and high recovery

3.

The pulsation curve is saw-tooth wave shape facilitate heavy mineral to settling

4.T

he equipment has high stability, simple operation and convenient maintenance.

5.

Achieve a good result in processing such as placer gold, tungsten, tin, hematite, manganese, barite, and gemstone etc.

6.

the stroke and stroke of each trough can be adjusted independently, and the selected

Specification

|

Model

|

Feeding Size(mm)

|

Water Added(m³/t)

|

Capacity(t/h)

|

Power(kw)

|

|

JT0.57-1

|

<6

|

1-2

|

1-3

|

1.5

|

|

JT1-1

|

<10

|

2-3

|

2-4

|

2.2

|

|

JT2-2

|

<10

|

2-4

|

4-8

|

3

|

|

JT3-1

|

<10

|

3-6

|

6-10

|

5.5

|

|

JT4-2

|

<25

|

4-8

|

10-15

|

7.5

|

|

JT4-2A

|

<25

|

4-8

|

10-15

|

4x2

|

|

JT5-2

|

<10

|

3-6

|

12-20

|

7.5

|

Application

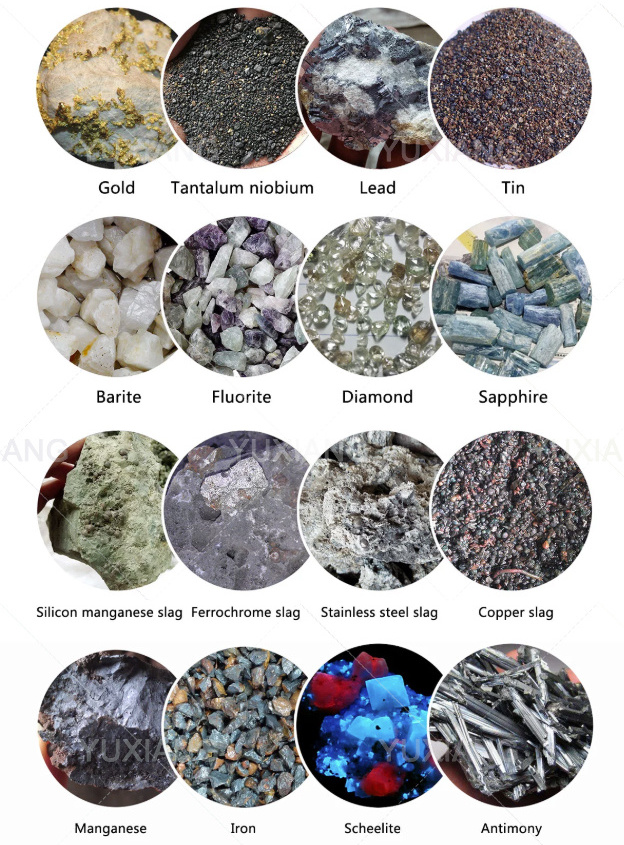

It is widely used to separator tungsten, tin, gold, red iron, brown iron, manganese, titanium, antimony, lead, tantalum, niobium and other minerals.

Product Structure

Working Principle

The jigging machine is stratified according to the jig bed theory. The jig pulsation curve is zigzag shape, so that the rising water flow is faster than the falling water flow. The rising time is short and the failing time is long. Strength the looseness of the bed, and make the heavy ore particles in the mineral setting fully. Water and raw ore will be fed from one end of the jigger screen, the ore granules will move in the vertical alternative water-flows. Layers will be formed because of density difference of materials. The minerals with small density will be in the up layer and will flow together with the up pulp flow while material with bigger density will be in the down layer and will discharged from the down discharging port as jigging concentrate.

Product Case

Hot Searches