- Product Details

- {{item.text}}

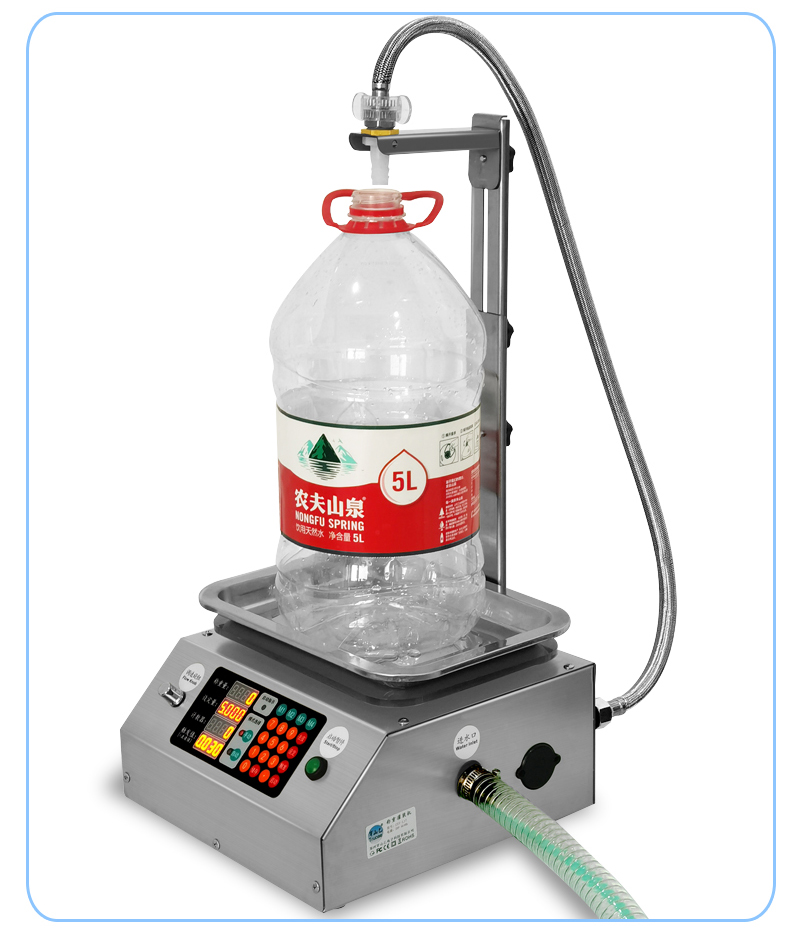

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

220V 50HZ

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Qinbiao

-

Dimension(L*W*H):

-

18*18*12

-

Weight:

-

3 KG

-

Model:

-

QB-3200

-

Rated power:

-

30w

-

Maximum flow rate:

-

3.2L/min

-

Use capacity:

-

8g-3kg

-

Filling error:

-

≤ 1g

-

Filling height:

-

0-32cm adjustable

-

Package size:

-

35 * 23 * 19cm

Quick Details

-

Machinery Capacity:

-

Other

-

Packaging Material:

-

Glass

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice, Other

-

Filling Accuracy:

-

99%

-

Voltage:

-

220V 50HZ

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Qinbiao

-

Dimension(L*W*H):

-

18*18*12

-

Weight:

-

3 KG

-

Model:

-

QB-3200

-

Rated power:

-

30w

-

Maximum flow rate:

-

3.2L/min

-

Use capacity:

-

8g-3kg

-

Filling error:

-

≤ 1g

-

Filling height:

-

0-32cm adjustable

-

Package size:

-

35 * 23 * 19cm

Product Description

1. There are 8 types of liquid filling machines mainly sold by our company.

The basic functions and parameters are as follows.

① Panel display: weight, setting quantity, counter, trigger value and flow rate value are displayed by LED digital tube.

② Basic functions: real-time weighing, overload alarm, automatic counting, automatic start, automatic speed reduction, automatic stop, data storage, flow rate adjustment, weight calibration, quantitative filling according to time, factory setting recovery and other functions.

③ Each model has an English version, with foreign plugs and English instructions.

② Basic functions: real-time weighing, overload alarm, automatic counting, automatic start, automatic speed reduction, automatic stop, data storage, flow rate adjustment, weight calibration, quantitative filling according to time, factory setting recovery and other functions.

③ Each model has an English version, with foreign plugs and English instructions.

2. What is the difference between diaphragm pump, gear pump and peristaltic pump?

① Diaphragm pump: pump is pumped by the suction of the inner membrane of the pump chamber, which is similar to the pumping principle of a syringe. The liquid will pass through the pump chamber.

② Gear pump: the liquid is transported by two gears rotating, which can be understood as two gears pulling the liquid out, and the liquid will pass through the pump cavity and gear.

③ Peristaltic pump: water is pumped by squeezing the water pipe, that is, the roller squeezes the hose from the outside to squeeze the liquid out, and the liquid only passes through the water pipe. The advantages are: clean and pollution-free, easy to change pipes and clean. The disadvantages are: high power consumption, low efficiency, slow speed, large jitter and high price.

3. How to distinguish different models of machines?

Answer: Look at the pump. Different models of machines and pumps are different, as shown in the following figure.

① Diaphragm pump: pump is pumped by the suction of the inner membrane of the pump chamber, which is similar to the pumping principle of a syringe. The liquid will pass through the pump chamber.

② Gear pump: the liquid is transported by two gears rotating, which can be understood as two gears pulling the liquid out, and the liquid will pass through the pump cavity and gear.

③ Peristaltic pump: water is pumped by squeezing the water pipe, that is, the roller squeezes the hose from the outside to squeeze the liquid out, and the liquid only passes through the water pipe. The advantages are: clean and pollution-free, easy to change pipes and clean. The disadvantages are: high power consumption, low efficiency, slow speed, large jitter and high price.

3. How to distinguish different models of machines?

Answer: Look at the pump. Different models of machines and pumps are different, as shown in the following figure.

The above four machines are small machines (18cm wide)!

Small machines are designed with wide voltage: they can supply 110-220V power for global use;

All small machines are mainframe size: 18 * 18 * 10cm (length * width * height)

Small machines are all packed in size: 35 * 23 * 19cm (4 # carton)

Small machines are designed with wide voltage: they can supply 110-220V power for global use;

All small machines are mainframe size: 18 * 18 * 10cm (length * width * height)

Small machines are all packed in size: 35 * 23 * 19cm (4 # carton)

The above four machines are big machines (26cm wide)!

Large machines are designed with narrow voltage: choose 110V or 220V when purchasing;

The width of the main machine is 26cm (different models have different heights)

Large machines are packed in size: 35 * 35 * 35cm (L13 is: 40 * 40 * 40)

Large machines are designed with narrow voltage: choose 110V or 220V when purchasing;

The width of the main machine is 26cm (different models have different heights)

Large machines are packed in size: 35 * 35 * 35cm (L13 is: 40 * 40 * 40)

4. What is the difference between the corrosivity of corrosive liquids?

① Acid: sulfuric acid, hydrochloric acid, etc. Corrosive to metal and rubber, generally not plastic.

② Alkali: sodium hydroxide, etc. It is corrosive to rubber, but not to metals and plastics.

③ Solvent: mainly refers to organic solvent, alcohol (ethanol), gasoline, methanol, etc. Soluble plastic and rubber.

5. What is the tolerance difference between different tubes?

① Silicone tube: not resistant to strong alkali and oil. No reaction except strong base and hydrofluoric acid.

② PVC pipe: resistant to acid and alkali solvents. It is resistant to most inorganic acids (except fuming sulfuric acid and

concentrated nitric acid), alkalis, most organic solvents (such as ethanol, gasoline and mineral oil) and inorganic salts, and is

suitable for chemical anti-corrosion materials.

③ 304 stainless steel: acid resistant. It has strong corrosion resistance. It also has good corrosion resistance to alkali

solution and most organic and inorganic acids.

Note: If the liquid has only weak acidity, alkalinity or solubility, it can be ignored, and all machines and pipes can bear it.

① Acid: sulfuric acid, hydrochloric acid, etc. Corrosive to metal and rubber, generally not plastic.

② Alkali: sodium hydroxide, etc. It is corrosive to rubber, but not to metals and plastics.

③ Solvent: mainly refers to organic solvent, alcohol (ethanol), gasoline, methanol, etc. Soluble plastic and rubber.

5. What is the tolerance difference between different tubes?

① Silicone tube: not resistant to strong alkali and oil. No reaction except strong base and hydrofluoric acid.

② PVC pipe: resistant to acid and alkali solvents. It is resistant to most inorganic acids (except fuming sulfuric acid and

concentrated nitric acid), alkalis, most organic solvents (such as ethanol, gasoline and mineral oil) and inorganic salts, and is

suitable for chemical anti-corrosion materials.

③ 304 stainless steel: acid resistant. It has strong corrosion resistance. It also has good corrosion resistance to alkali

solution and most organic and inorganic acids.

Note: If the liquid has only weak acidity, alkalinity or solubility, it can be ignored, and all machines and pipes can bear it.

Specification

|

Filling machine parameter table

|

|

|

|

|

|

|

|

|

||||||||

|

Product model

|

QB-M90

|

QB-1200

|

QB-3200

|

QB-3500

|

QB-L13

|

QB-L15

|

QB-L17

|

QB-L36

|

||||||||

|

Recommended filling

|

0.5-10g

|

2-300g

|

8-1000g

|

10-1000g

|

0.02-5kg

|

0.02-8kg

|

0.03-10kg

|

0.03-30kg

|

||||||||

|

Maximum weighing

|

500g

|

800g

|

3kg

|

3kg

|

8kg

|

10kg

|

15kg

|

30kg

|

||||||||

|

Weighing accuracy

|

0.1g

|

0.5g

|

1g

|

1g

|

2g

|

2g

|

5g

|

5g

|

||||||||

|

Pump type

|

Peristaltic pump

|

Peristaltic pump

|

Diaphragm pump

|

Peristaltic pump

|

Peristaltic pump

|

Gear pump

|

Diaphragm pump

|

Diaphragm pump

|

||||||||

|

Maximum flow rate

|

90ml/min

|

1.2L/min

|

3.2L/min

|

2.5L/min

|

8L/min

|

12L/min

|

17L/min

|

36L/min

|

||||||||

|

Filling error

|

≤0.1g

|

≤0.2-0.5g

|

≤1g

|

≤1g

|

≤2g

|

≤2g

|

≤2-5g

|

≤5g

|

||||||||

|

Support height

|

0-20cm

|

0-20cm

|

0-32cm

|

0-32cm

|

0-40cm

|

0-40cm

|

0-40cm

|

0-40cm

|

||||||||

|

Water pipe material

|

Silica gel tube

|

Silica gel tube

|

Silica gel tube

|

Silica gel tube

|

Silica gel tube

|

PVC steel wire pipe

|

PVC steel wire pipe

|

PVC steel wire pipe

|

||||||||

|

Water pipe specification

|

3*5mm

|

6*9mm

|

7*10mm

|

7*11mm

|

9.6*16.6mm

|

19*25mm

|

19*25mm

|

25*31mm

|

||||||||

|

Water pipe length

|

1+0.33m

|

1.5m

|

1.5+0.5m

|

1.5+0.5m

|

2m

|

1.5+0.5m

|

2+0.8m

|

2+1m

|

||||||||

|

Host size

|

18*18*12cm

|

18*18*12cm

|

18*18*12cm

|

18*18*12cm

|

26*26*23cm

|

26*27*20cm

|

26*26*15cm

|

26*26*15cm

|

||||||||

|

Package size

|

35*23*19cm

|

35*23*19cm

|

35*23*19cm

|

35*23*19cm

|

35*35*35cm

|

35*35*35cm

|

35*35*35cm

|

35*35*35cm

|

||||||||

|

Packing weight

|

2kg

|

2.5kg

|

2.7kg

|

3kg

|

12.5kg

|

12.5kg

|

8.8kg

|

13kg

|

||||||||

|

Power

|

10w

|

20w

|

30w

|

40w

|

150w

|

200w

|

200w

|

300w

|

||||||||

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches