- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TD-1200,TD-2200

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

4.1x0.9x1.7m

-

Year:

-

2023

-

Weight (KG):

-

10000 kg

-

Power (kW):

-

11

-

Product name:

-

Factory price Single Hook And Double Hook Tyre Debeader

-

Application:

-

Tire recycling plant

-

Raw material:

-

Nylon tire , steel tire , truck tire

-

Related machine:

-

Tyre shredding plant

-

Keyword:

-

Debeader

-

Machine Type:

-

Hydraulic fully automatic

-

Function:

-

Take out the bead wire before shredding..

-

Usage of final product:

-

Rubber tile , reclaimed rubber making ,rubber wheel

-

Speed:

-

1pcs/min

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huarui

-

Marketing Type:

-

High Productivity

-

Model Number:

-

TD-1200,TD-2200

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

4.1x0.9x1.7m

-

Year:

-

2023

-

Weight (KG):

-

10000 kg

-

Power (kW):

-

11

-

Product name:

-

Factory price Single Hook And Double Hook Tyre Debeader

-

Application:

-

Tire recycling plant

-

Raw material:

-

Nylon tire , steel tire , truck tire

-

Related machine:

-

Tyre shredding plant

-

Keyword:

-

Debeader

-

Machine Type:

-

Hydraulic fully automatic

-

Function:

-

Take out the bead wire before shredding..

-

Usage of final product:

-

Rubber tile , reclaimed rubber making ,rubber wheel

-

Speed:

-

1pcs/min

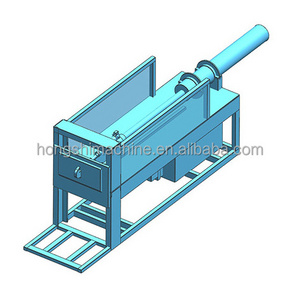

Product Description

Hydraulic Tire Debeader

Tire de-beading, as the first step in waste tire recycling, really plays an irreplaceable role.Tire debeader is specially designed to pull out the bead wires inside tire sidewalls completely before the shredding process, especially for the waste tire with the diameter of less than 1200mm. Prior to shredding, de-beading can produce cleaner end product, providing less wear of shredder. After de-beading, the subsequent waste tire shredding can be processed smoothly.

Features of Tire Debeader

* The hook is made of welded alloy, sturdy and wearable surface.

*Tire debeader has protective frame, effectively avoid the insecurity when pulling the bead ring.

* Motor and reducer are integrated, the structure is compact.

* Equipped with integral base pedestal, easy installation and operation.

*The hydraulic system adopts international advanced plunger pump technology,low noise, high pressure and high stability.

Specification of machine

|

Model No.

|

TD-1200 single hook tire debeader

|

|

|

Feed size of tire

|

≤φ1300mm

|

|

|

Capacity

|

30-40 tires/hour

|

|

|

Power

|

11kw

|

|

|

Overall dimensions

|

4.7*0.9*1.7m

|

|

|

Equipment weight

|

1.8ton

|

|

|

Contact:Bella Qin , Whatsapp/Wechat 0086 13937476212

|

|

|

How to Debead Tire Wires

Tire debeader consists of rack motor, hydraulic system, drawing hook, drawing mouth, etc. Driven by motor, the hydraulic system and oil cylinder can make the hook do reciprocating motion. Put the whole tire on the drawing mouth and hook the inner ring of the waste tire.Due to the enormous pressure of oil cylinder, the bead ring can be pulled out completely. Besides,the drawing mouth can accelerate the shredding of rubber in the tire side-wall,thereby finishing the smooth removal of bead ring.

Detailed photos

Packaging and Shipping

Company Introduction

Xuchang Huarui Machinery Co., Ltd. is specialized in producing the tire recycling plant for nearly 30 years and we provide 2 years warranty for our machines

We provide the most suitable proposal according to client's demand , any needs , please contact

:

Bella Qin , Whatsapp/Wechat 0086 13937476212

FAQ

--1--Q: How to choose a suitable tire recycling line?

A: Please tell us the end product you want to produce, rubber block or rubber powder, and the HOUR CAPACITY & OUTPUT SIZE, we will recommend you the most suitable tire recycling line.

--2--Q: What size of rubber powder can i get from the recycling line?

A: 5-40 mesh rubber powder.

--3--Q: Can we get very fine powder from the recycling line?

A: Yes, you can get 40-100mesh fine rubber powder with fine grinder system.

--4--Q: Can you process OTR tires?

A: Yes, we have machines special for OTR tires.

--5--Q: What about the machine installation?

A: We will send engineers to customer working site for the installation guidance, commissioning and training when everything is ready on the working site, like power, cable, labors, forklift, etc.

--6--Q: How about the spare parts?

A: We will send one set spare parts for free with machine. And if more, spare parts will be sold at cost price permanently and will give you the spare parts list when you purchase machine.

--7--Q: Will you test the machine before delivery?

A: Yes, we will test every machine and production line before delivery and send you the working video. You also can come to us for inspection before delivery.

--8--Q: How about the delivery time and packing details?

A: 20 days after receiving the deposit. Package in the whole container.

Hot Searches