- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0-100kw

-

Dimension(L*W*H):

-

customized

-

Weight:

-

380 KG

-

Machinery Capacity:

-

60-80 kegs/H

-

Product Name:

-

Keg washing and filling machine

-

Heating Way:

-

Steam Heating/Electric Heating

-

Production Capacity:

-

60-80 kegs/H

-

Washing Stations:

-

1-2

-

Application:

-

Beer keg

-

Material:

-

SUS304/SUS316

-

Model:

-

Manuel/Semi-auto/Full-auto

-

Washing Method:

-

Invert Washing

-

Applicable Kegs:

-

Keg250-500mm,Height 360-600mm

-

Color:

-

customized

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tonsen

-

Voltage:

-

380V customized

-

Power:

-

0-100kw

-

Dimension(L*W*H):

-

customized

-

Weight:

-

380 KG

-

Machinery Capacity:

-

60-80 kegs/H

-

Product Name:

-

Keg washing and filling machine

-

Heating Way:

-

Steam Heating/Electric Heating

-

Production Capacity:

-

60-80 kegs/H

-

Washing Stations:

-

1-2

-

Application:

-

Beer keg

-

Material:

-

SUS304/SUS316

-

Model:

-

Manuel/Semi-auto/Full-auto

-

Washing Method:

-

Invert Washing

-

Applicable Kegs:

-

Keg250-500mm,Height 360-600mm

-

Color:

-

customized

*Shandong Tonsen Equipment Co., Ltd is an international comprehensive enterprise, specializing in beer equipment, wine equipment, whiskey equipment and other fermentation system equipment, integrating R&D, production, sales, technical support and service.

*The product includes a variety of large, medium and small brewery equipment, hotel, bar home-brewed beer equipment, teaching experiment etc. And could be used to brew various types of wine, beer, barley-bree (whisky) brandy. We supply brewing of main and auxiliary raw material, technical training, secondary equipment and control equipment, of course, can customize according to customer required special specifications design, production, installation of equipment and other products.

*Our brewhouse system separated to 2 vessels, 3 vessels, 4vessels and 5 vessels, capacity from 100L to 20000L, use electric or steam heat. Semi-automatic control and easy to operate.

The table below are for reference.

1. Manual keg washer.

*Main function and feature

(1)Pipeline use steel edge which could ensure no-leaking and long life.

(2)With CO2 pressurization function.

(3)Manual operations, convenient and flexible.

(4)Applicable for all kegs with keg spear.

2. Semi-auto single head keg washer.

*Main function and feature

(1)All procedures are thoroughly controlled by SIEMENS programmable controller. All parameters (time values) can be adjusted without stopping the machine.

(2)Two sets of washing process for customers to choose.

(3)Disinfectant and Caustic could be used repeatedly to save water

(4)Water tank possess heating function, the temperature can be displayed on screen.

(5)With steam sterilization function (user-selectable).

3. Semi-auto two head keg washer.

*Main function and feature

(1)All procedures are thoroughly controlled by SIEMENS programmable controller. All parameters (time values) can be adjusted without stopping the machine.

(2)Two sets of washing process for customers to choose.

(3)Disinfectant and Caustic could be used repeatedly to save water

(4)Water tank possess heating function, the temperature can be displayed on screen.

(5)With steam sterilization function (user-selectable).

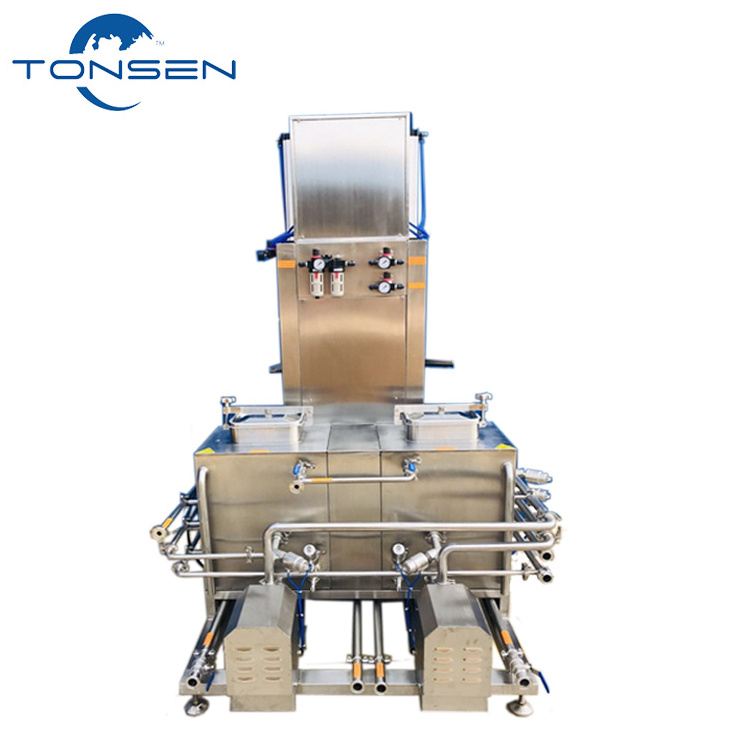

4. Beer Keg Washing and Filling AIO Machine(table board fixed).

*Main function and feature

(1)Automatic control by PLC, all parameters can be adjusted through touch screen.

(2) Cleaning and filling process can be finished in this machine at one time.

(3) All use pneumatic double acting Angle seat valve which could ensure the action sensitivity and reliability

(4) With unique pressure maintaining system,performance stable and reliable, beer loss minimum.

(5) With CIP automatic cleaning system

5.Beer Keg Washing and Filling AIO Machine(table board lifting).

*Main function and feature

(1) Automatic control by PLC, all parameters can be adjusted through touch screen.

(2) Cleaning and filling process can be finished in this machine at one time.

(3) With unique pressure maintaining system,performance stable and reliable, beer loss minimum.

(4) With CIP automatic cleaning system

(5) Table board is lifting, and convenient to take kegs, labor-saving and time-saving.

6. Single Station Beer Keg Filling Machine.

*Main function and feature

(1) All procedures are thoroughly controlled by SIEMENS programmable controller. All parameters (time values) can be adjusted without stopping the machine.

(2) Pressure maintaining system performance is stable and reliable, to make sure the lowest beer loss compared to other similar products.

(3) Could fill the kegs with different volume directly, and do not need to adjust any parameter

(4) Equipment with CIP circumfluence pipe, very easy operation.

7. Double Stations Beer Keg Filling Machine without flowmeter.

*Main function and feature

(1) All procedures are thoroughly controlled by SIEMENS programmable controller. All parameters (time values) can be adjusted without stopping the machine.

(2) Two filling stations with separate control systems.

(3) Pressure maintaining system performance is stable and reliable, to make sure the lowest beer loss compared to other similar products.

(4) Could fill the kegs with different volume directly, and do not need to adjust any parameter

8. Two Stations Beer Keg Filling Machine with flow meter.

*Main function and feature

(1)With flow meter, can control the filling amount precisely, not affected by the size of the keg.

(2) All procedures are thoroughly controlled by SIEMENS programmable controller. All parameters (time values) can be adjusted without stopping the machine.

(3) Germany import flow meter, accurate measurement, high precision

(4) Two filling stations with separate control systems,can fill kegs with different volume separately.

(5) The LCD screen can display filling process synchronously, and also can count the quantity of kegs and the total filling volume.

1) All tanks will be packed with soft protection material and mounted on steel frame

2) All accessories and spare parts will be packed with soft protection material and then put into iron box

3) After loaded into containers, all equipment will be fixed to the containers.

1.Free consultation service before, during and after sales.

2.Project planning and design the layout service.

3.Management of equipment's long distance shipping from seller's factory to named port or station by buyer.

4.Training of equipment maintenance and operation personally.

5.New production techniques.