- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/415V/440V or customized

-

Dimension(L*W*H):

-

680*680*230mm etc.

-

Weight:

-

180 kg

-

Core Components:

-

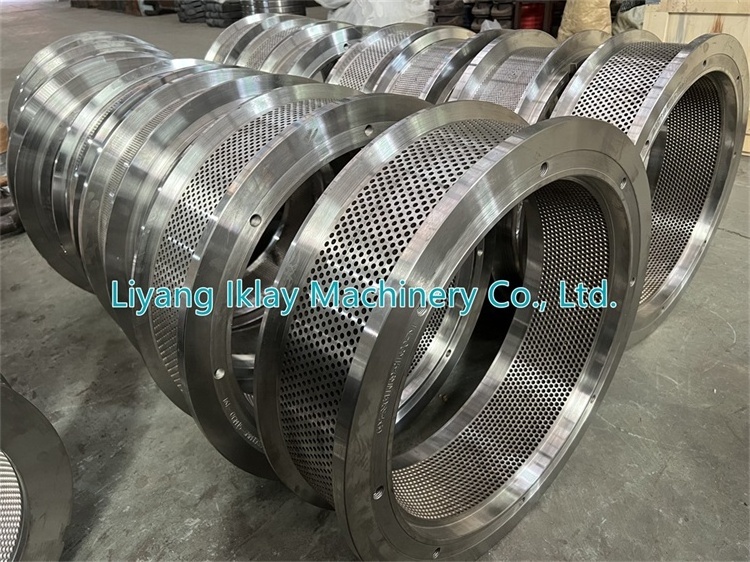

Ring die/ Rollers

-

Diameter:

-

1.2-18mm

-

Usage:

-

Making Wood Pellets or Animal Feeds or Cat Litter

-

Compression Ratio:

-

Customized

-

Process:

-

Using CNC Gun Drilling Machine+Countersinking

Quick Details

-

Max. Capacity:

-

5000pc/ year

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

IKLAY

-

Voltage:

-

380V/415V/440V or customized

-

Dimension(L*W*H):

-

680*680*230mm etc.

-

Weight:

-

180 kg

-

Core Components:

-

Ring die/ Rollers

-

Diameter:

-

1.2-18mm

-

Usage:

-

Making Wood Pellets or Animal Feeds or Cat Litter

-

Compression Ratio:

-

Customized

-

Process:

-

Using CNC Gun Drilling Machine+Countersinking

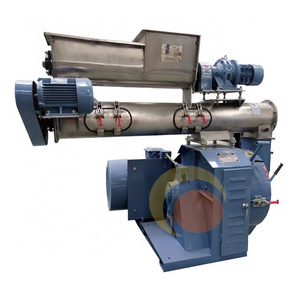

Our factory LIYANG IKLAY MACHINERY CO., LTD. is specialized for ring dies/ flat dies, pellet mill matrixes, rollers, roller assemblies, spare parts for pellet mill and so on.

We can customize various models

PELLET MILL RING DIES/ FLAT DIES& ROLLERS for pellet machine

, such as MZLH, SZLH(Zhengchang),

La Meccanica,

SZLJ, HKJ, CPM, OGM, IDAH,

SALMATEC,

Amandus Kahl, MUZL/

FAMSUN

,

Van Arson, PTN, Andritz PM, Shenda,

Yemmak, CPP, Awila, Yulong XGJ and so on.

Following are some models:

| Pellet Mill Brand | Model | ||||

| CPM |

3016-4,

3016-5, 3020-6, 3020SW, 3022-6, 3022SW |

7722-4,

7722-6, 7722-7, 7726-7, 7726SW |

7730-6,

7730-7, 7730-8, 7730SW, 7930-4, 7930-6, 7930-8 |

7932-5,

7932-9, 7932-11, 7932-12, 7936-12, 7936-14 |

9036-9,

9042-12, 9046-12, 9046-14 |

| Buhler |

Buhler 304.58,

Buhler 304.78, Buhler 420.108 (DMFJ) (DPCB), Buhler 420.138 (DFPB) (DFPC) |

Buhler 520.138 (DPBA) (DPUC) , Buhler 520.178 (DPBS)

|

SZLH400,

SZLH420, SZLH520, AHHB530, AHHC520, AHHD660, AHPE900 |

Buhler 660.138 (DPAB),

Buhler 660.178 (DPAA), Buhler 660.228 (DPAS), Buhler 660.265 (DPHD) |

Buhler 900.178

(DPGC), Buhler 900.228 (DPGB), Buhler 900.300 (DPHE) |

| Amandus Kahl |

Kahl 14-175,

Kahl 24-390 |

Kahl 33-390,

Kahl 33-500, Kahl 38-600 |

Kahl 35-780,

Kahl 38-780, Kahl 37-850 |

Kahl 39-1000,

Kahl 40-1000 |

Kahl 45-1250,

Kahl 60-1250, Kahl 60-1500 |

| Zhengchang |

SZLH250,

SZLH300, SZLH320, SZLH350 |

SZLH400,

SZLH420, SZLH508, SZLH528 |

SZLH558,

SZLH858, SZLH660X |

SZLH400D,

SZLH420D, SZLH678D, SZLH768D |

SZLH420b,

SZLH428, SZLH1068, SZLH508E, SZLH1208 |

|

Famsun

(Muyang) |

MUZL350,

MUZL420, MUZL420TW, MUZL610, MUZL610TW |

MUZL1210,

MUZL1610, MUZL2010, MUZL600, MUZL1200, MUZL1200A |

K15 (SZLH535×190) ,

K20 (SZLH575×205), K25 (SZLH575×210) , K30 (SZLH635×220) |

K35 (SZLH685×245),

K40 (SZLH785×270), K60 (SZLH985×340), K70 (SZLH1070×370) |

MUZL420M,

MUZL610M, MUZL1210M, MUZL1610M |

| Yulong |

XGJ560,

XGJ850, |

HKJ250,

HKJ320, HKJ350 |

HKJ400,

HKJ420, HKJ508 |

||

| PTN |

PTN580,

PTN580-C |

PTN HB 150,

PTN 650 |

PTN Progress 580-2,

PTN Progress 850.210, PTN Progress 900 |

||

| Yemmak |

Yemmak 420.106

Yemmak 420.108 Yemmak 420.138 |

Yemmak 520.138

Yemmak 520.175 |

Yemmak 660.178

Yemmak 660.228 |

Yemmak 900.228

|

|

| La Meccanica |

Lamec 200.35,

Lamec 304 LG, Lamec 304.58, Lamec 304.78 |

Lamec 420.108,

Lamec 420.138, Lamec 520.138, Lamec 520.138, Lamec 520.170 |

Lamec 630.150,

Lamec 630.200, Lamec 630.240, |

Lamec 800.150 C LG,

Lamec 800.185 C, Lamec 800.220, Lamec 800.220 C, Lamec 800.250 C |

Lamec 935,

Lamec 935 C |

| Munch |

RMP 350.100,

RMP 520.1380, RMP 520.178 |

RMP 660.138,

RMP 660.178, RMP 660.228 |

RMP 680.230,

RMP 700.230, RMP 800.265 |

||

| SALMATEC |

Salmatec Maxima 500,

Salmatec Maxima 580, Salmatec Maxima 620, |

Salmatec Maxima 700.170,

Salmatec Maxima 700.225, |

Salmatec SPM 840.180,

Salmatec SPM 840.240, Salmatec Maxima 840/3 |

||

| OGM |

OGM-1.5,

OGM-0.8, OGM-6 |

||||

PRODUCT DETAILS

Our ring dies/flat dies are suitable for:

1. Biomass pellet machine: wood pellet machine/ pellet mill, sawdust pellet machine, grass pellet machine, straw pellet machine, crop straw pellet machine, alfalfa pellet machine, coffee ground powder pellet mill and etc.

2. Livestock and poultry/aqua feed pellet machine: pig/cattle/sheep/chicken/duck/fish/shrimp......

3. Cat litter granulator/ pellet mill

4. Compound fertilizer

| Material | Hardness | Diameter | Outer diameter |

| X46Cr13/4Cr13(stainless steel);20MnCr5/20CrMnTi(Alloy Steel) | HRC54-60 | 1.0mm-28mm | <1800mm |

Following are our factory's processing technology and advantages. If you're interested, please do not hesitate to contact us.

Please tell us: model of pellet mill, hole diameter, compression ratio, material. We can quote you for checking.

1. Materials Forging/ Ring Rolling Process

---We choose China TOP1 forging factory's raw materials, usage life can be enhanced about 15%. Less impurities and high purity.

2. Rough Lathing Process (Before drilling) / Fine Lathing Process (After finished)

--- We use automatic CNC lathing machine to lathe ring dies/ flat dies.

3. Drilling Holes Process

--- All pellet mill dies are drilled by automatic CNC gun drilling machines to ensure inner holes mirror polishment, good smooth, high polished and good forming.

--- All ring dies are countersinked by automatic CNC countersinking machines to ensure its smooth and uniform.

--- Choosing vacuum furnace processing technology to ensure long service life; Stainless steel/ SS ring die can reach

HRC 54-58, Alloy steel/ AS ring die can reach HRC57-60. More wear-resistant and corrosion-resistant.

6. Quality Inspection For Each Process

--- We arrange the quality inspector to check the quailty for each process, strictly control the quality to guarantee final pellet dies are good.

7. Packing Process

--- After quality inspection is no problem, we will arrange the packing with wood boxes to make sure cargoes are in good condition during transportation.

8. More Photos for Our Pellet Dies/ Ring Dies/ Rollers which produced before

We can customize any model as long as you tell us your pellet machine model, hole diameter, compression ratio, materials and size.