Safe control with emergency button

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

15 kw

-

Dimension(L*W*H):

-

1600*1330*1650 mm

-

Weight:

-

2000

-

Applicable Industries:

-

Metallurgical Equipment

-

Product name:

-

ORGSJ-185 High Speed Thread Rolling Machine

-

Speed of mainshaft(r/min):

-

20,25,41,51,64

-

Active spindle feed speed(mm/s):

-

5mm/s

-

Maximum rolling pressure(kn):

-

180

-

Maximum width of roller(mm):

-

120

-

Angle of inclination of principal axis:

-

±5°

-

Spindle center distance(m):

-

120-240

-

Function:

-

Hydraulic Thread Rolling Machine

-

Usage:

-

High Quality Thread Rolling Machine

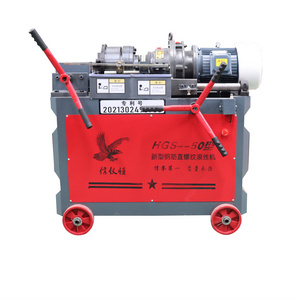

Quick Details

-

Place of Origin:

-

Henan, China

-

Application:

-

Metallurgical Equipment, Low Price Thread Rolling Machine

-

Brand Name:

-

ORANGE MECH

-

Voltage:

-

380V

-

Power:

-

15 kw

-

Dimension(L*W*H):

-

1600*1330*1650 mm

-

Weight:

-

2000

-

Applicable Industries:

-

Metallurgical Equipment

-

Product name:

-

ORGSJ-185 High Speed Thread Rolling Machine

-

Speed of mainshaft(r/min):

-

20,25,41,51,64

-

Active spindle feed speed(mm/s):

-

5mm/s

-

Maximum rolling pressure(kn):

-

180

-

Maximum width of roller(mm):

-

120

-

Angle of inclination of principal axis:

-

±5°

-

Spindle center distance(m):

-

120-240

-

Function:

-

Hydraulic Thread Rolling Machine

-

Usage:

-

High Quality Thread Rolling Machine

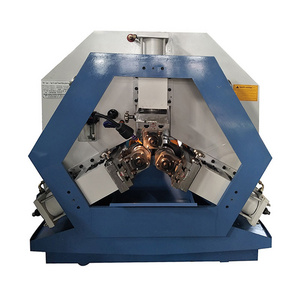

Thread Rolling Machine

1.Two spindle of the machine rotates synchronously in the same direction .Right spindle feed motion in the horizontal direction under the rolling drive.Two rolling wheels make the work as required and other thread shape by rolling.

2.This machine is mainly composed of an organism, rotating box, fixed spindle seat , a movable spindle seat, hydraulic system and electrical parts etc.

3.The fixed seat and the movable seat main function is installing the screw rolling wheel and adjusting the rolling wheel tooth.

4.This machine is a hydraulic power system, it is mainly to make the active spindle seat to feed and return .

5.The two spindle seat adjust center respectively.Angle of table axis can be adjusted in the plus or minus 3 degrees.Each shaft to feed the workpiece can be determined according to the parameters of workpiece and mechanical properties of materials.

CHARACTERISTICS:

Thread rolling machine with stable structure, excellent technology, convenient maintenance, reasonable price, welcome by the user's product to the radial and axial machining, match with corresponding processing thread rolling wheel can ordinary bolts, special bolts, tong wire (teeth), the machine structure is reasonable, simple and convenient manipulation, reliable quality, is the production of non-standard thread, standard parts (bolts) ideal equipment.

Control Panel

Thread Rollers

Rolling of straight teeth, oblique teeth and helical splines; straightening, reducing diameter, rolling light and all kinds of forming rolling.

Activities of the main shaft

The two spindles of this machine rotate in the same direction synchronously and the moving spindle is driven by hydraulic force to make the feed motion in the horizontal direction.

Full casting structure

Cast iron fuselage + excellent steel, long service life

|

Model

|

ORGSJ-185

|

ORGSJ-200

|

|

Speed of mainshaft(r/min)

|

20、25、41、51、64

|

20、25、41、51、64

|

|

Active spindle feed speed(mm/s)

|

5mm/s

|

5mm/s

|

|

Active power(kw)

|

11

|

11

|

|

Hydraulic power(kw)

|

4

|

5.5

|

|

Maximum rolling pressure(kn)

|

180

|

200

|

|

Diameter of rolling material(mm)

|

φ6-φ65

|

φ6-φ100

|

|

Maximum diameter of roller(mm)

|

φ190-φ220

|

φ190-φ220

|

|

Aperture of roller(mn)

|

φ75

|

φ75

|

|

Maximum width of roller(mm)

|

120

|

180

|

|

Length of thread

|

unlimited

|

unlimited

|

|

Angle of inclination of principal axis

|

±5°

|

±10°

|

|

Spindle center distance(m)

|

120-240

|

150-300

|

|

Total weight(kg)

|

2000

|

3000

|

|

Dimension(mm)

|

1600*1330*1650

|

1790*1730*1430

|

2.Our workshop:

3.Packing & shipment:

1.Warranty All the products have one year guarrantee.

2.Training We provide training to make sure every customer can install and operate the machines.

3. Spare parts We provide all spare parts for all machine in lifetime use.

4.Standby Servive We are always ready to help. Just let us know whenever you have questions or problems.

Question 1: What are your advantages compared with your competitors?

Answer:

With rich industry experience and strict Product Quality Control systems, we provide:

1. Stable and reliable product at reasonable price

2. Good customer service: Fast response to any inquiry or question

3. On-time delivery.

Question 2: Are you manufacturer?

Answer: Yes, we are manufacturer with more than 10 years' experience.

Question 3: Can I print my Logo on the machine?

Answer: Yes, sure.

Question 4: Can you customize the machine for me ?

Answer: Yes, we can customize according to customer's requirements.

Question 5: What shall we do if breakdown occurs?

Answer: Please informed us once the breakdown occurs. During warranty period, if breakdown occurs, we shall respond in time after receiving the notification of the buyer. We shall handle failure over the telephone/ fax or arrange relevant personnel to the site according to the buyer's requirements.

Question 6: Which ports do you usually ship at?

Answer: We can load container at: Qingdao, Shanghai, Ningbo, Tianjin, Guangzhou etc.