- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.01

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

0.1~1.4%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

STD

-

Brand Name:

-

DKJL

-

Product name:

-

chrome magnesite bricks

-

MgO:

-

60-80%

-

Density:

-

2.4g/cm3

-

Size:

-

230*114*65

-

Refractoriness:

-

≤1790℃

-

Packing:

-

wood pallet

-

Standard:

-

ASTM,JIS

-

Porodity:

-

23%

-

Working temp:

-

1520C

-

Cr2O3:

-

6-20%

Quick Details

-

SiO2 Content (%):

-

20%

-

Al2O3 Content (%):

-

>65%

-

MgO Content (%):

-

0.5%

-

CaO Content (%):

-

0.01

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

0.1~1.4%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

STD

-

Brand Name:

-

DKJL

-

Product name:

-

chrome magnesite bricks

-

MgO:

-

60-80%

-

Density:

-

2.4g/cm3

-

Size:

-

230*114*65

-

Refractoriness:

-

≤1790℃

-

Packing:

-

wood pallet

-

Standard:

-

ASTM,JIS

-

Porodity:

-

23%

-

Working temp:

-

1520C

-

Cr2O3:

-

6-20%

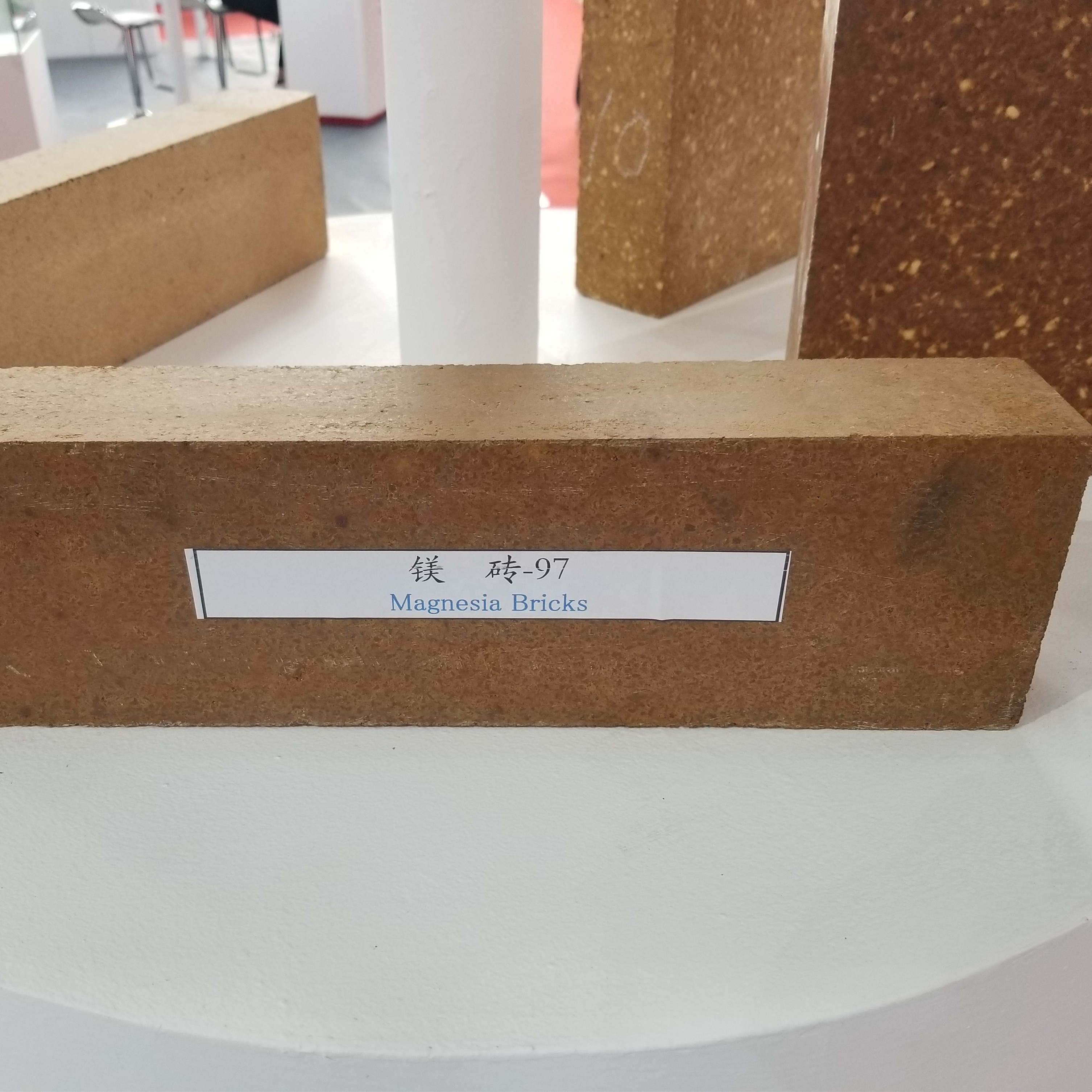

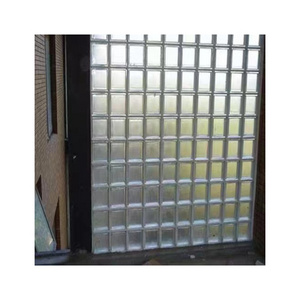

Glass kiln used chrome magnesite bricks for sale

Magnesites bricks for general uses are mainly made from super quality Bauxite, bonding chamotte and additives, being high pressure pressed and sintered in high temperature.

Application of chrome magnesite bricks

Magnesite bricks were widely used in all parts of furnace lining of metallurgic, petroleum, construction materials, machinery and militaries, etc.

Features and advantages of chrome magnesite bricks

The dimensions are more exactly.

chrome magnesite refractory bricks physical and chemical index:

|

Item |

Direct bonded magnesia chrome brick |

Semi bonded magnesia chrome brick |

Semi bonded again magnesia chrome brick |

Bonded again magnesia chrome brick |

|||||

|

DMC-12 |

DMC-8A |

DMC-8B |

DMC-8C |

BMGe |

ZBDMGe-16 |

ZBDMGe-16 |

ZDMGe-16 |

ZDMGe-20 |

|

|

MgO≥% |

60 |

80 |

78 |

75 |

72 |

60 |

55 |

65 |

60 |

|

Cr2O3≥% |

12 |

8 |

8 |

8 |

6 |

16 |

20 |

16 |

20 |

|

SiO2≥% |

32 |

1.2 |

1.5 |

2.5 |

3.5 |

1.5 |

1.5 |

1.2 |

1.2 |

|

Apparent Porosity % |

18 |

18 |

8 |

18 |

18 |

17 |

17 |

16 |

16 |

|

Bulk Density g/cm3 |

3.0 |

3.0 |

3.0 |

3.0 |

2.95 |

|

|

|

|

|

Cold Crushing Strength Mpa |

40 |

45 |

45 |

45 |

40 |

40 |

40 |

45 |

45 |

|

0.2Mpa Refractoriness Under Load T0.6 |

1600 |

1700 |

1700 |

1680 |

1600 |

1750 |

1750 |

1750 |

1750 |

|

Thermal expansion1400°C≤% |

1.4 |

1.6 |

1.6 |

1.6 |

|

|

|

|

|

|

Heat and shock stability(1100°C water cooling) |

5 |

6 |

6 |

6 |

5 |

|

|

|

|

|

Application |

cement rotary kiln, Steelmaking electric line furnace, non-ferrous metallurgical furnace, lime kiln |

Widely used in RH, VOD and color metallurgy furnace |

|||||||