- Product Details

- {{item.text}}

Quick Details

-

MF:

-

non

-

EINECS No.:

-

non

-

Place of Origin:

-

Hebei, China

-

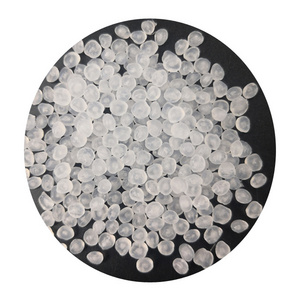

Appearance:

-

White section granules

-

Package:

-

25kg/bag

-

Recommend addition%:

-

6-8%

-

Reference standard:

-

UL94

-

Melt indexer g/10min:

-

2.42

-

Grade:

-

Eco-friendly

Quick Details

-

CAS No.:

-

non

-

Purity:

-

100%

-

Other Names:

-

non

-

MF:

-

non

-

EINECS No.:

-

non

-

Place of Origin:

-

Hebei, China

-

Appearance:

-

White section granules

-

Package:

-

25kg/bag

-

Recommend addition%:

-

6-8%

-

Reference standard:

-

UL94

-

Melt indexer g/10min:

-

2.42

-

Grade:

-

Eco-friendly

Features

1.By introducing strong polar sulfone group instead of isopropyl group in tetrabromobisphenol S bis (2, 3-dibromopropyl) ether

molecule, the problem of flame retardant modification of copolymer PP is solved, and it is also suitable for flame retardant

modification of high grade PP nozzle material or reclaimed material.

2.Polymer activation treatment, good compatibility with polymer.

3.High flame retardant efficiency, small amount of addition, to solve the problem of high cost of flame retardant modification of

copolymer PP; Especially recommended for high performance copolymer PP flame retardant.

4.High decomposition temperature, excellent thermal stability and light stability.

molecule, the problem of flame retardant modification of copolymer PP is solved, and it is also suitable for flame retardant

modification of high grade PP nozzle material or reclaimed material.

2.Polymer activation treatment, good compatibility with polymer.

3.High flame retardant efficiency, small amount of addition, to solve the problem of high cost of flame retardant modification of

copolymer PP; Especially recommended for high performance copolymer PP flame retardant.

4.High decomposition temperature, excellent thermal stability and light stability.

Remarks

1.Directly apply to injection, recommend use in K8303 or EPS30R, dosage of masterbatch suggest at 7-8%.

2. Used for automobile bellows and threading pipes, masterbatch recommend 3-4%.

3.

For modification of granules, recommend QB-T02, dosage at 3%

4.The detail dosage, no need add compound antimony oxide, the best dosage based on the exact test.

|

Model

|

Copolymerization PP flame retardant masterbatch

|

remarks

|

|

Appearance

|

White section granules

|

1. Meet EU environmental requirement

2.Supply SGS report

|

|

Melt indexer g/10min

|

2.42

|

2.Supply SGS report

|

|

Content of flame retardant%

|

≥80%

|

|

|

Melting temperature℃

|

≥130℃

|

|

|

Decomposition temperature℃

|

≥300℃

|

|

|

Recommend addition %

|

5-8%

|

|

|

Reference standard

|

UL94

|

|

Hot Searches