- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

1564654814

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Yongjia

-

Model Number:

-

SPC-1002

-

Type:

-

road glue

-

Name:

-

polyurethane adhesive glue

-

Custom Order:

-

Available

-

Material:

-

Polyol+Isocyanate

-

Viscosity:

-

2000-3000cps

-

Appearance:

-

Brown Viscous Liquid

-

Advantage:

-

Environmental Protection

-

Feature:

-

Short curing time, even at low temperatures

-

Application:

-

Road Construction

-

Mixing Ratio:

-

A:B=4:1

-

Certificate:

-

MSDS RoHS

Quick Details

-

CAS No.:

-

16554613548

-

Other Names:

-

PU polyurethane adhesive sealant

-

MF:

-

-NH-CO-NH-[CH2]n-NH-CO-NH-

-

EINECS No.:

-

1564654814

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Yongjia

-

Model Number:

-

SPC-1002

-

Type:

-

road glue

-

Name:

-

polyurethane adhesive glue

-

Custom Order:

-

Available

-

Material:

-

Polyol+Isocyanate

-

Viscosity:

-

2000-3000cps

-

Appearance:

-

Brown Viscous Liquid

-

Advantage:

-

Environmental Protection

-

Feature:

-

Short curing time, even at low temperatures

-

Application:

-

Road Construction

-

Mixing Ratio:

-

A:B=4:1

-

Certificate:

-

MSDS RoHS

Polyurethane adhesives have lower temperature and ultra-low temperature properties than all other types of adhesives. Polyurethane adhesives have excellent shear strength and impact resistance, are suitable for a variety of structural bonding applications, and have excellent flexibility properties. At the same time, it has excellent rubber properties and can adapt to the adhesion of different thermal expansion coefficient substrates. It forms a soft-hard transition layer between the substrates, which not only has strong bonding force, but also has excellent cushioning and shock absorption functions.

|

Contents

|

Component A

|

Component B

|

|

|

Description

|

Blended Polyol

|

Polymeric isocyanate (MDI)

|

|

|

Appearance

|

Light Yellow Homogeneous Liquid

|

Dark Brown Viscous Liquid

|

|

|

Mixing Ratio (W)

|

A:B=1:4

|

|

|

|

Cure Time (20℃)

|

48~52 second

|

|

|

Application

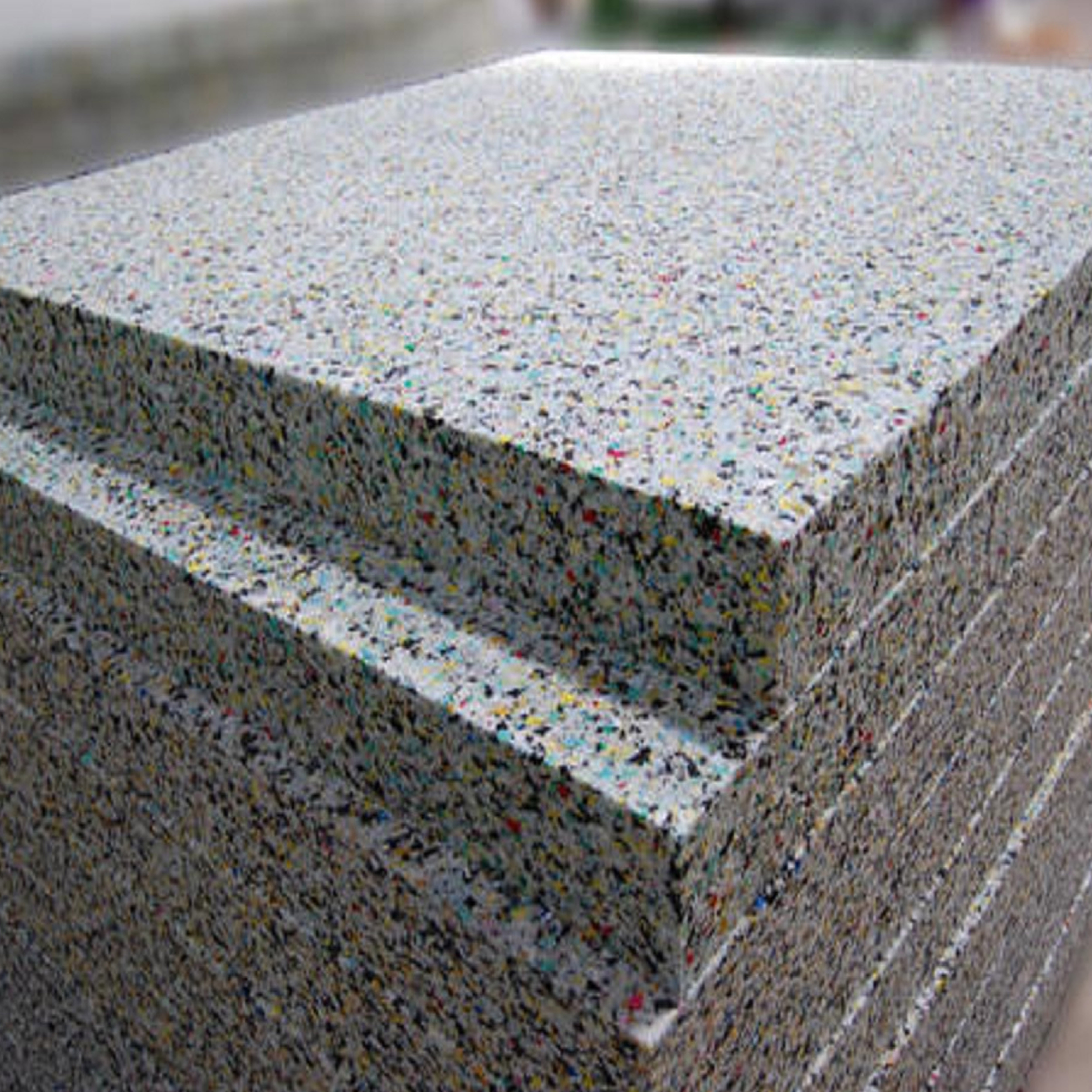

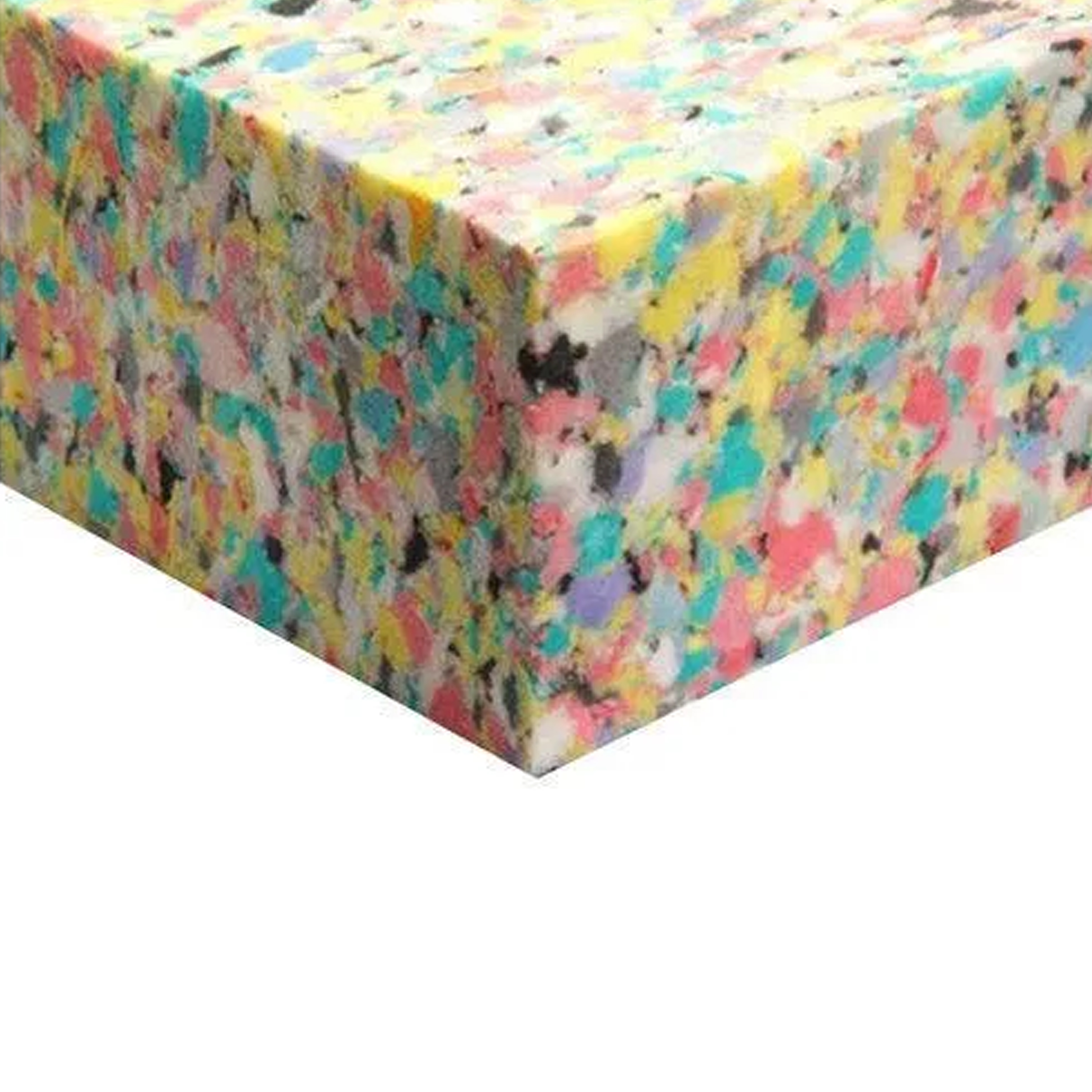

Bonded foam belongs to the recycling of industrial waste of polyurethane products. Its use value is no less than that of sponges. It is made of industrial sponge waste after crushing, stirring glue, steam high-temperature sterilization, deodorization and compression molding. The production cost is greatly reduced in terms of production cost. It has good elasticity, good resistance, no deformation, and no peculiar smell. It can be made into products of various densities according to customer needs. The high-density and high-elasticity regenerated sponge reaches a density of 60 kg/m3 Above, it has the characteristics of high-efficiency flame retardancy, good tensile force, high elasticity, and no deformation. After being sterilized and deodorized by high-pressure steam, it is environmentally friendly, economical and practical. It can be widely used to make sofas, mattresses, boss chairs, sports equipment, such as sponge gymnastic mats, sponge fitness mats, sponge wrestling mats, sponge car seat cushions and other products. This product has been widely accepted by countries all over the world.

Hot Searches