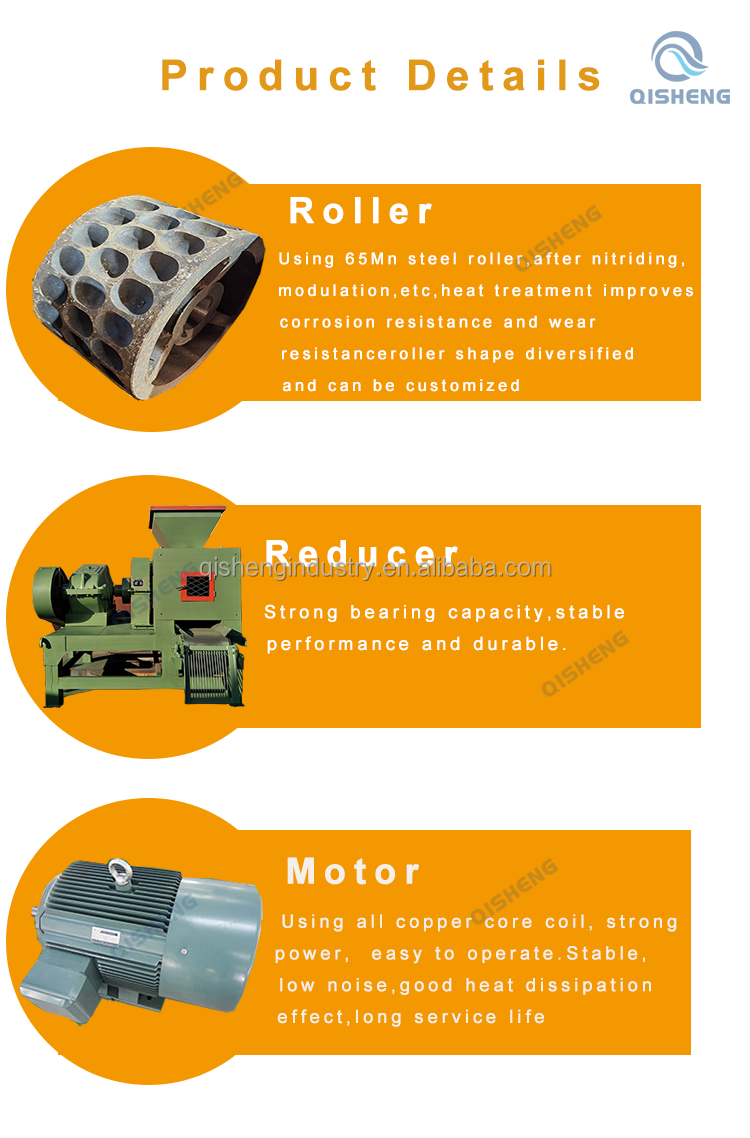

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

QISHENG

-

Voltage:

-

380V or customized voltage

-

Weight:

-

1250 KG

-

Dimension(L*W*H):

-

1.3x1.15x2.05 m

-

Product name:

-

double roller zeolite powder pulverized coal briquetting machine

-

Raw material:

-

Coal powder,Charcoal powder,carbon black powder ,etc

-

Usage:

-

Make coal briquettes with high density

-

Briquette shape:

-

Square, ball ,egg-shaped, round, oval, and column,pillow type

-

ROLLER diameter:

-

360mm

-

Roller Width:

-

250mm

-

Host power:

-

7.5kw

Quick Details

-

Warranty:

-

1 Year

-

Marketing Type:

-

Hot Product 2022

-

Core Components:

-

roller

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

QISHENG

-

Voltage:

-

380V or customized voltage

-

Weight:

-

1250 KG

-

Dimension(L*W*H):

-

1.3x1.15x2.05 m

-

Product name:

-

double roller zeolite powder pulverized coal briquetting machine

-

Raw material:

-

Coal powder,Charcoal powder,carbon black powder ,etc

-

Usage:

-

Make coal briquettes with high density

-

Briquette shape:

-

Square, ball ,egg-shaped, round, oval, and column,pillow type

-

ROLLER diameter:

-

360mm

-

Roller Width:

-

250mm

-

Host power:

-

7.5kw

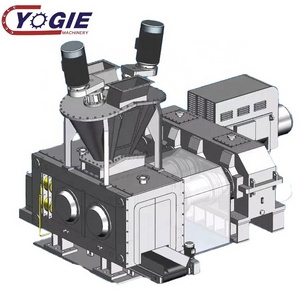

High pressure phosphate powder pelletizer double roller zeolite powder pulverized coal briquetting machine

Product Description

Charcoal coal briquette machines, also called charcoal briquette granulator, is used to process the charcoal powder into charcoal briquettes. Mature technology, stable performance and easy operation, our charcoal powder briquette machine enjoys extensive popularity among clients. With high Calorific value and density, the charcoal briquettes produced by our charcoal powder briquette machine are most suitable for industrial boilers, home heating, barbecue, etc.

Working principle of charcoal ball briquitte machine:

From the storage silo, the material is fed into the molding machine hopper evenly by the quantitative device. Then the regulation board on the hopper make the materal evenly enter into the middle of the roller; the reverse operating roller compress the material and the forming pressure increases gradually, at the centerline of the roll the forming pressure reaches its maximum value, once the material through the line, the molding pressure rapidly decrease so that the material forms into ball shape and smoothly discharge the ball.

Application:

Coal Charcoal ball press briquetting machines and coal briquette machines are widely used in refractory, powder plant, metallurgical, chemical engineering, energy, transportation, heating and other industries.

Product Flow:

Raw materials---crushing---feeding---mixing---briquetting---drying---finished products

Technical parameters of charcoal ball briquitte machine:

|

Model

|

Power

|

Capacity

|

Diameter of roller

|

Width of roller

|

Size

|

Weight

|

|||||

|

QS-290

|

5.5 kw

|

1-3 t/h

|

290 mm

|

200 mm

|

1.24x1.07x1.44 m

|

900 kg

|

|||||

|

QS-360

|

7.5 kw

|

4-6 t/h

|

360 mm

|

250 mm

|

1.3x1.15x2.05 m

|

1250 kg

|

|||||

|

QS-400

|

11 kw

|

6-7 t/h

|

400 mm

|

300 mm

|

1.65x1.50x2.40 m

|

4000 kg

|

|||||

|

QS-450

|

15 kw

|

8 t/h

|

450 mm

|

300 mm

|

1.65x1.50x2.40 m

|

4200 kg

|

|||||

|

QS-500

|

18.5 kw

|

8-10 t/h

|

500 mm

|

350 mm

|

1.75x1.60x2.60 m

|

4500 kg

|

|||||

|

QS-650

|

30 kw

|

10-15 t/h

|

650 mm

|

380 mm

|

2.2x2.2x2.8 m

|

5000 kg

|

|||||

|

QS-850

|

55 kw

|

15-20 t/h

|

850 mm

|

650 mm

|

3.5x3.5x3 m

|

10000 kg

|

|||||

|

QS-1000

|

75 kw

|

20-30 t/h

|

1000 mm

|

850 mm

|

4.5x4.5x3 m

|

15000 kg

|

|||||

|

Remarks

|

The above parameters are for reference only, and there may be slight differences in the actual situation. Please refer to the actual situation

|

|

|

|

|

|

|||||

Raw materials requirements

coal powder, charcoal powder, metallic powder (FeSi powder), iron scale, iron sludge, precipitator dust, iron concentrate, raw material powder, manganese ore fines, slime peat, fireproof material, desulfurized gypsum

1.Mateials size required before feeding into briquette machine,less than 3mm.If the size is larger than 3mm,it is necessary to crush into smaller size for briquette;

2.Moisture content:around 10%;

Rollers/Moulds and final products

1,The finished products usually 20-60mm.

2,The final products are smokeless, non-toxic, none peculiar and environmental protection.

3,The shape can be Square, ball egg-shaped, round, oval, and column, strip-type, elliptic type,pillow type and other special shapes by customizing the matching molds.

Packing & Delivery

Packaging:

1) Standard wooden case packing, nude packing

2) As require your requirements.

Shipping:

1) Professional goods shipping forklift.

2) Port:Qingdao.

Delivery:

within 7-30 days after receiving the payment.

Why Choose Us

♦Pre-sales:

1 Perfect 7*24hours inquiry and professional consulting service

2.Visit our factory anytime

♦Sale:

1. Update the production schedule in time

2. Quality supervision

3. Product acceptance

4. Shipping on time

♦After-sales:

1. Guarantee:1 year ,during this period we will offer free spare parts if they are broken.

2. Training how to install and use machine

3. Engineers available to service overseas

4. Skill support during the whole using life

Hot Searches