- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YULONG

-

Model Number:

-

YL-G-JC

-

Surface Treatment:

-

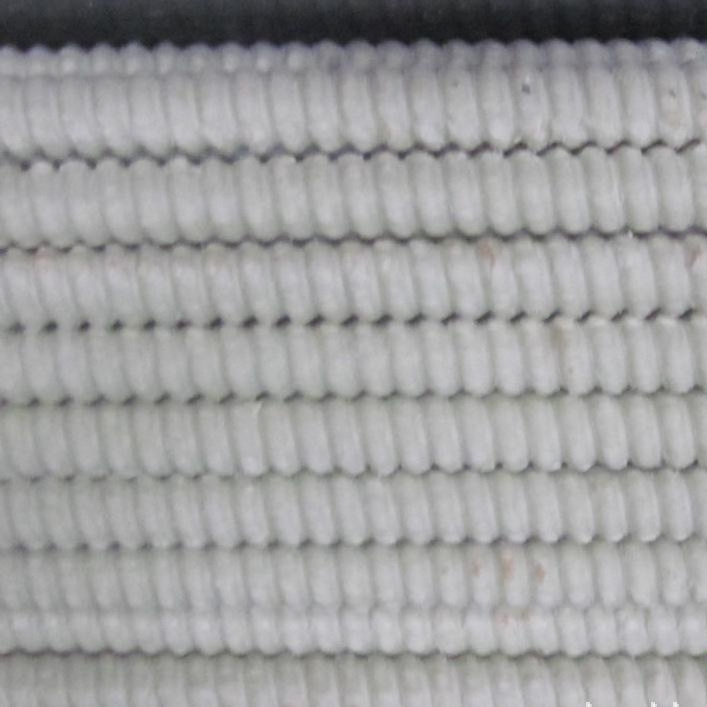

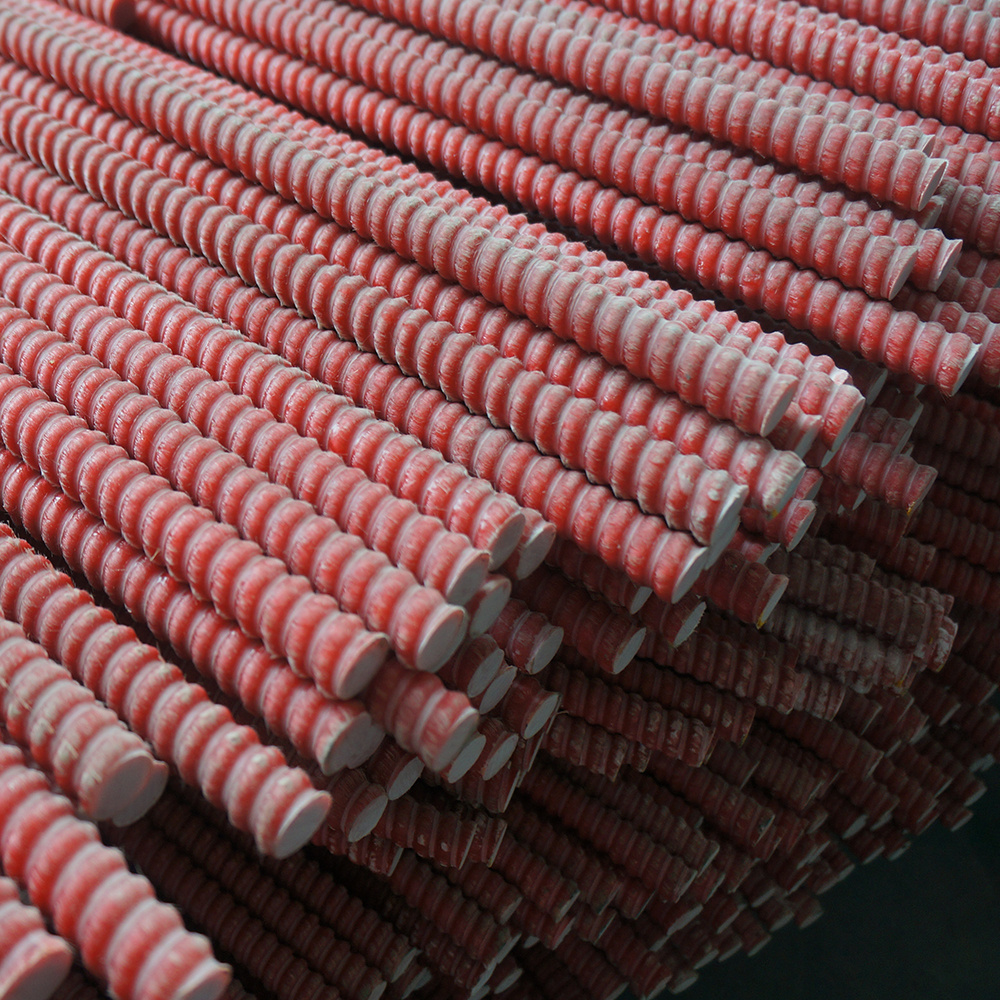

fully threaded, sand coated

-

Feature:

-

Durable,light,High strength,Fire retardant

-

Production Process:

-

pultrusion

-

Raw materials:

-

Fiberglass, unsaturated resin

-

Size:

-

Customized from 4~40mm

-

MOQ:

-

1 ton

-

Product name:

-

Fiberglass rebar,FRP rebar,Grp Rebar

-

Trade term:

-

EXW,FOB,CIF

-

Certificate:

-

ISO9001

Quick Details

-

Application:

-

reinforce floors, roads, airports

-

Technique:

-

pultrusion

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

YULONG

-

Model Number:

-

YL-G-JC

-

Surface Treatment:

-

fully threaded, sand coated

-

Feature:

-

Durable,light,High strength,Fire retardant

-

Production Process:

-

pultrusion

-

Raw materials:

-

Fiberglass, unsaturated resin

-

Size:

-

Customized from 4~40mm

-

MOQ:

-

1 ton

-

Product name:

-

Fiberglass rebar,FRP rebar,Grp Rebar

-

Trade term:

-

EXW,FOB,CIF

-

Certificate:

-

ISO9001

Products Description

Fiberglass Rebar

is a Spiral Wrapped Structural Reinforcing Rod made from a combination of fiberglass roving and resin. Developed as a superior alternative to steel in concrete reinforcement, FRP Rebar is suitable for applications requiring a lightweight material that has high tensile strength, with non-corrosive and non-conductive properties. For example, properly reinforced FRP concrete slabs exposed to heavy traffic, such as bridge decks and driveways, last approximately 20 times longer than conventional methods.

FRP rebar Application:

1. Concrete bridge structure

2. Anti-corrosion construction

3. Underground project

4. Road Construction

5. Seaport/Dock/Coastal/Parking and etc concrete area

6. Low conductive and Non-magnetic field

7. Threaded rebar / anchor bolt to be available as reinforced material

1. Concrete bridge structure

2. Anti-corrosion construction

3. Underground project

4. Road Construction

5. Seaport/Dock/Coastal/Parking and etc concrete area

6. Low conductive and Non-magnetic field

7. Threaded rebar / anchor bolt to be available as reinforced material

FRP rebar benefits:

* Tensile Strength is Greater than Steel

* Electrically and thermally non-conductive

* Transparent to Magnetic Fields & Radar Frequencies

* Extremely Lightweight - 75% Lighter than Steel Rebar

* Will Never Corrode - Conservative Estimates Indicate Longevity Over 100 Years

* Electrically and thermally non-conductive

* Transparent to Magnetic Fields & Radar Frequencies

* Extremely Lightweight - 75% Lighter than Steel Rebar

* Will Never Corrode - Conservative Estimates Indicate Longevity Over 100 Years

Product Paramenters

|

Yulong FRP Rebar parameters

|

|

|

|

|

|

|

||||||

|

FRP Rebar

|

Diameter(mm)

|

Area(cm2)

|

Unit weight(Kg/m)

|

UTS(Mpa)

|

Ultimate Cutting strength(Mpa)

|

Elasticity modulus

(Gpa)

|

||||||

|

001

|

4

|

0.12

|

0.032

|

1500

|

>150

|

>40

|

||||||

|

002

|

6

|

0.28

|

0.051

|

1280

|

>150

|

>40

|

||||||

|

003

|

8

|

0.50

|

0.098

|

1080

|

>150

|

>40

|

||||||

|

004

|

10

|

0.73

|

0.150

|

980

|

>150

|

>40

|

||||||

|

005

|

12

|

1.03

|

0.210

|

870

|

>150

|

>40

|

||||||

|

006

|

14

|

1.34

|

0.275

|

764

|

>150

|

>40

|

||||||

|

007

|

16

|

1.80

|

0.388

|

752

|

>150

|

>40

|

||||||

|

008

|

18

|

2.48

|

0.485

|

744

|

>150

|

>40

|

||||||

|

009

|

20

|

2.78

|

0.570

|

716

|

>150

|

>40

|

||||||

|

010

|

22

|

3.55

|

0.700

|

695

|

>150

|

>40

|

||||||

|

011

|

25

|

4.78

|

0.970

|

675

|

>150

|

>40

|

||||||

|

012

|

28

|

5.90

|

1.195

|

702

|

>150

|

>40

|

||||||

|

013

|

30

|

6.71

|

1.350

|

637

|

>150

|

>40

|

||||||

|

014

|

32

|

7.40

|

1.520

|

626

|

>150

|

>40

|

||||||

Hot Searches