- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

PPD

-

Weight:

-

600 KG

-

Dimension(L*W*H):

-

1850*1500*1450mm

-

Model:

-

PPD-ST

-

Total Power:

-

50Hz 2.6KW

-

Speed:

-

60-100pck/minute

-

Pack Size:

-

L 50-100 mm*W 35-80 mm

Quick Details

-

Voltage:

-

220V, 220V

-

Power:

-

2.6kw

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

PPD

-

Weight:

-

600 KG

-

Dimension(L*W*H):

-

1850*1500*1450mm

-

Model:

-

PPD-ST

-

Total Power:

-

50Hz 2.6KW

-

Speed:

-

60-100pck/minute

-

Pack Size:

-

L 50-100 mm*W 35-80 mm

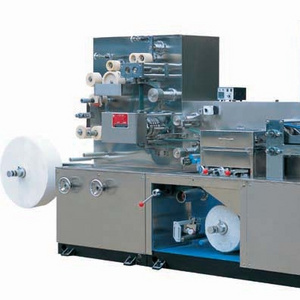

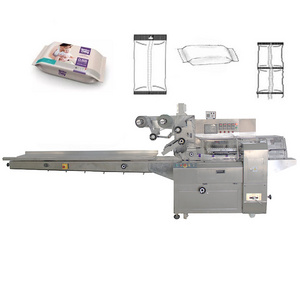

Single Bag Fully Automatic Electric 2.6kw Wet Tissue Paper Making Packing Machine

| Item No | Single Bag Fully Automatic Electric 2.6kw Wet Tissue Paper Making Packing Machine |

| Key Work | Wet Tissue Making Machine |

|

Towelette unfolded size |

80-200mm x 70-200mm |

|

Towelette folded size |

40-100x20-60mm Adjustable |

|

Towelette Material width |

70-220mm |

|

Packing Material |

Aluminum Paper Heat-Sealable Packaging Material,Diameter≤320mm,Width≤320mm |

|

Suitable Towelette Material |

Roll,30-60g/mm,Spunlace Non-woven Cloth,Wet Strength Paper |

| Pack Size | Single Pack 50-100mmx35-80mm |

| Folding Method | Vertical Max 8 Times,Horizontal 1-2Times |

| Raw Material Paper Core ID | Φ 76.2mm (=3") |

| Usage | Wet Tissue Packing Machine For Wipes/Towels etc |

| Delivery | 30 Days After Payment |

Single Pack Fully Automatic Wet Tissue Making Packing Machine

1. Single pack moist towelette manufacturing machine is designed by pneumatic pressing for selaing method.it is widely used for manufacturing 4 side sealing and packing mahcine for different towelette ,such as moist towelette,refreshing towelette,feminine wipes,cleansing wipes etc.

2. By changing the sealing moulding, The different size of towelette can be work on the machine.

3. Machine is fully automatic production for PLC control + LCD touch screen operation.

4.

The different material of towelette are acceptable

,spunlace nonwoven.wet strength paper etc.

5.

The different liquid are catering for the machine

,povindone iodine,BZK,alcohol,soap etc.

6. The liquid pumping system adopts the high precise of Swiss made Electromagnetic pump.

Production line:

Raw materials onto the machine→6(max 8)folding Longitudinally→3 times folding crosswisely→cutting→spraying→into packages→sealing→cutting→product.