- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Shinely

-

Warranty:

-

12 Months

Quick Details

-

Car Fitment:

-

bmw, Universal

-

Main Material:

-

Steel

-

Size:

-

290*170mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Shinely

-

Warranty:

-

12 Months

Advantages & services

Products Description

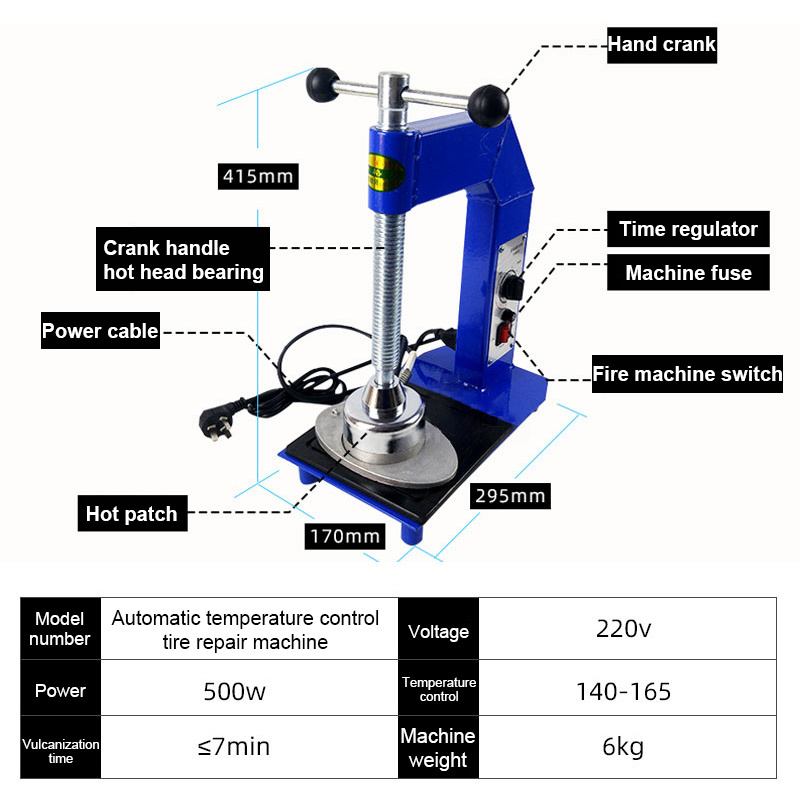

Features:

* Easily Adjust pressure with lever adjustment.

* Easily repair inside of inner tubes, car outer tube, and tubeless tyres.

* Safety time setting of up to 120 min.

* Simple, one-man operation.Repairs tread, shoulder and sidewall .

* Large-capacity, fully rotating C-frame accommodates different wheel sizes and allows for vertical or horizontal repairs .

* Vulcanizing repair process cures the patch and inner tire lining to form a dense, sealed repair job .

* An adjustable, swing-open, rotating C-frame cavity simplifies tire loading and unloading while maximizing stability

|

Product Name

|

Tire mending machine

|

|

Raw Material

|

Steel

|

|

Size

|

295*170MM

|

|

Application

|

Tire Rapair machine

|

|

Usage

|

Vulcanizing

|

|

Applicable cars

|

All

|

|

Packing

|

Color Box+carton

|

Tire repair method:

1、Clean the surface of the wound where the tire needs to be repaired and mark it.

2、Use a grinding machine to grind the surface of the wound, the area is slightly larger than the wound。

3、Use the brush to raw rubber and gasoline blending good mortar (or hot glue) evenly coated on the polished.。

4、Cut the appropriate size of the rubber, it will fill in the wound,

5、Pressure the hot head on raw rubber (if possible can pad a thin layer of aluminum or iron in the raw rubber), try to put the wound in the central heating head, pressing screw, fixed tires.

6、 Turn on the timer switch and set it in the right place, Cold start can refer to "20" (Or adjust the vulcanizing time according to the temperature and the condition of the wound) the heat start time can be a little shorter,if you do not need timing can be set on the manual gear, then the hot head to work.

7、At the end of vulcanization, tire repair machine automatically cut off power supply hot head.

Certifications

Exhibition

Hot Searches