- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DO

-

Voltage:

-

380V

-

Power:

-

10.5KW

-

Dimension(L*W*H):

-

3500*800*1400mm

-

Weight:

-

800 kg

-

Marketing Type:

-

New Product 2022

-

Input voltage:

-

380V

-

Machine power:

-

10.5KW

-

Processing speed:

-

0-4m/min

-

Minimum processing size:

-

40*40mm

-

Chamfer angle:

-

45 degrees

-

Machinable thickness:

-

1-20mm

-

Total machine weight:

-

800kg

-

Dimensions:

-

3500*800*1400mm

-

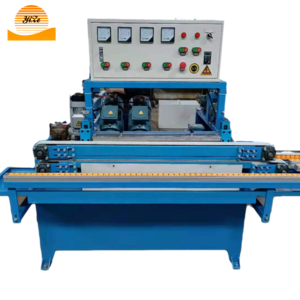

Product name:

-

Glass Manual Edge Polishing Machine

-

Type:

-

Automatic CNC Glass Machines

Quick Details

-

Machine Type:

-

edging machine

-

Glass Thickness:

-

1-20mm

-

Production Capacity:

-

/

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DO

-

Voltage:

-

380V

-

Power:

-

10.5KW

-

Dimension(L*W*H):

-

3500*800*1400mm

-

Weight:

-

800 kg

-

Marketing Type:

-

New Product 2022

-

Input voltage:

-

380V

-

Machine power:

-

10.5KW

-

Processing speed:

-

0-4m/min

-

Minimum processing size:

-

40*40mm

-

Chamfer angle:

-

45 degrees

-

Machinable thickness:

-

1-20mm

-

Total machine weight:

-

800kg

-

Dimensions:

-

3500*800*1400mm

-

Product name:

-

Glass Manual Edge Polishing Machine

-

Type:

-

Automatic CNC Glass Machines

Product Description

G

lass edger

Glass edging machine is one of the earliest and larger mechanical equipment in glass deep processing equipment. The main function is to smooth the glass and make some special shapes. Correct and reasonable use of the edging machine can not only ensure the normal production, but also prolong the life of the machine. It is divided into single-arm special-shaped edging machine, linear edging machine, and mold edging machine.

Precautions when using the linear edger: The working mode of the linear edger (straight edge machine, round edge machine, bevel edger) is to clamp the glass by the front and rear platens and drive its linear motion for grinding. Two points must be paid attention to when using:

①The joint surfaces of the front and rear pressure plates and the guide rails should be lubricated frequently, otherwise the normal service life of the machine will be affected due to the premature wear of the front and rear pressure plates and the working surfaces of the guide rails. Although some models have automatic lubricating devices, it is necessary to check whether the lubricating pipeline is smooth;

② The clamping force should be appropriate when clamping the glass, too loose will affect the grinding quality, too tight will increase the load of the machine, easy to produce shaking and crawling phenomenon, and it is easy to break the glass when grinding thin glass. The clamping force can be tested by clamping a slightly larger glass on the machine, that is, clamping the glass in the middle of the machine, and moving the glass with both hands when the machine is stopped.

Specification

|

Input voltage

|

380V

|

|

Machine power

|

10.5KW

|

|

Processing speed

|

0-4m/min

|

|

Minimum processing size

|

40*40mm

|

|

Chamfer angle

|

45 degrees

|

|

Machinable thickness

|

1-20mm

|

|

Total machine weight

|

800kg

|

|

Dimensions

|

3500*800*1400mm

|

|

Product name

|

Glass Manual Edge Polishing Machine

|

|

Type

|

Automatic CNC Glass Machines

|

Hot Searches