- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZHONGSHENG

-

Model Number:

-

ZS33

-

Surface Treatment:

-

POLISHED

-

Product name:

-

Vinyl seawall

-

Material:

-

Fiberglass Reinforce Polymer, ISO&Vinyl resin, fillers

-

Color:

-

Customized Color

-

Feature:

-

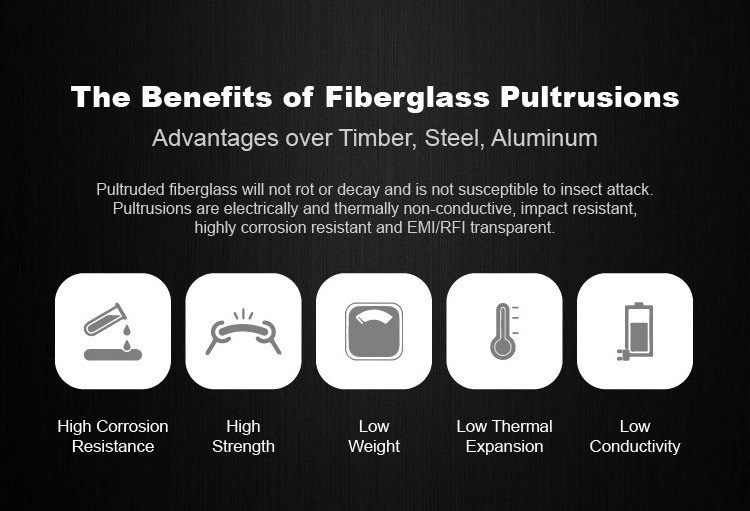

Corrosion Resistance, high strength, no rust, anit uv

-

Dimension:

-

customized design is acceptable

-

Certificate:

-

ISO9001:2015

-

Warranty:

-

1 YEAR

-

MOQ:

-

1000 meters

-

Package:

-

Pallet

-

Keywords:

-

Sheet Pile

Quick Details

-

Application:

-

CONSTRUCTION

-

Technique:

-

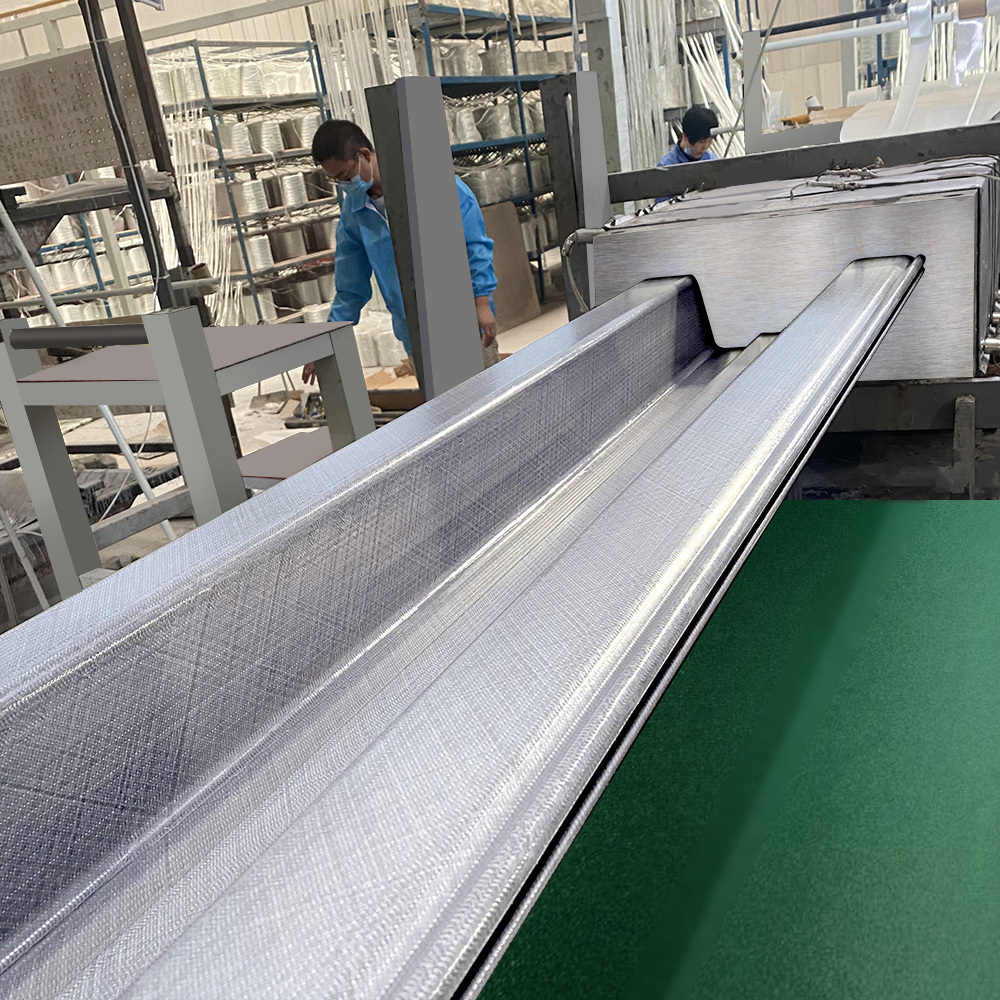

PULTRUSION

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZHONGSHENG

-

Model Number:

-

ZS33

-

Surface Treatment:

-

POLISHED

-

Product name:

-

Vinyl seawall

-

Material:

-

Fiberglass Reinforce Polymer, ISO&Vinyl resin, fillers

-

Color:

-

Customized Color

-

Feature:

-

Corrosion Resistance, high strength, no rust, anit uv

-

Dimension:

-

customized design is acceptable

-

Certificate:

-

ISO9001:2015

-

Warranty:

-

1 YEAR

-

MOQ:

-

1000 meters

-

Package:

-

Pallet

-

Keywords:

-

Sheet Pile

Products Description

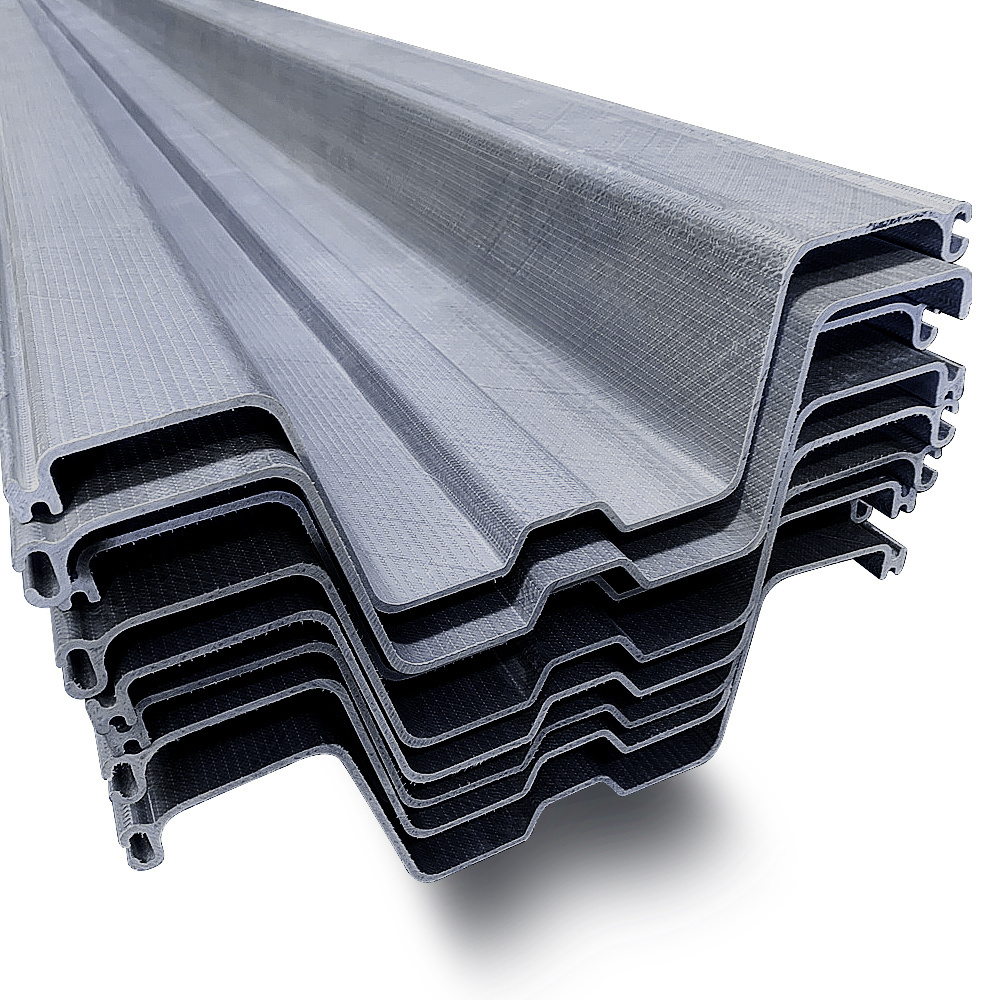

Vinyl seawall

ZHONGSHENG

vinyl seawall

manufactured by the pultrusion process and is designed to be able to weather the harsh marine environment. Many traditional methods of building seawalls from wood, steel, and even concrete simply cannot hold up over time.

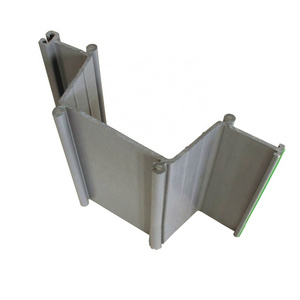

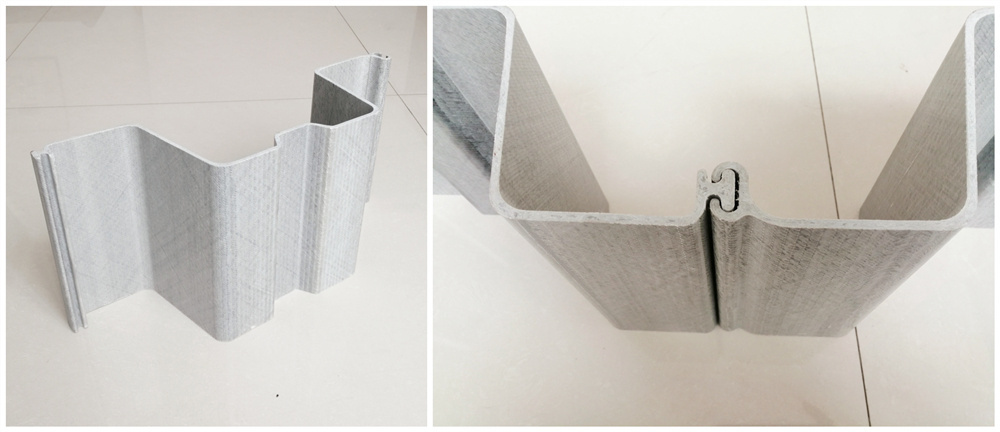

Vinyl seawall is an efficient and environmentally friendly alternative to steel sheet piling in marine structures, flood walls,and seepage barriers. It’s the strongest, most durable composite sheet piling profile available and often specified for bulkheads in areas that require heavy loading support.

Vinyl seawall is an alternative construction material without many of the performance disadvantages of conventional materials such as aluminum, concrete and wood. Vinyl seawall profile is cost effective, low maintenance cost, anti-corrosion and high strength for harsh environment applications.

Vinyl seawall is an efficient and environmentally friendly alternative to steel sheet piling in marine structures, flood walls,and seepage barriers. It’s the strongest, most durable composite sheet piling profile available and often specified for bulkheads in areas that require heavy loading support.

Vinyl seawall is an alternative construction material without many of the performance disadvantages of conventional materials such as aluminum, concrete and wood. Vinyl seawall profile is cost effective, low maintenance cost, anti-corrosion and high strength for harsh environment applications.

Benefits of vinyl seawall

At Decks & Docks, we believe vinyl seawall is one of the best seawall solutions for many waterfront properties, whether residential, commercial, or municipal.

COST-EFFECTIVE.

Vinyl seawall is easy to maintain and requires little maintenance.

ROT-RESISTANT.

Saltwater won’t negatively impact vinyl seawall.

UV PROTECTION.

Excess sun and heat can weaken other materials, but not vinyl.

DURABLE.

Vinyl seawall can last over 50 years. Because it is resistant to the issues that can damage other seawalls, such as rot, sun, and marine boring creatures, vinyl seawall will last much longer than seawalls composed of other materials.

EASY TO INSTALL.

Because the product is uniform and lightweight, vinyl seawall and vinyl pilings are easier to install than other materials.

GUARANTEED.

Product manufacturers offer exceptional warranties on vinyl seawalls—something you just won’t get with another seawall.

Z-profile

vinyl seawall

U-profile

vinyl seawall

Product Paramenters

|

Vinyl Seawall

|

|

|

|

|

|

|||||

|

Width(mm)

|

Height(mm)

|

Thickness(mm)

|

Weight Per Pile (kg/m)

|

Weight Per Wall (kg/m2)

|

Elastic Section Modulus (cm3/m)

|

|||||

|

500

|

160

|

6

|

7.2

|

14.4

|

502

|

|||||

|

600

|

230

|

7.5

|

11.1

|

18.5

|

920

|

|||||

|

437

|

254

|

10.5

|

11.6

|

26.54

|

1480

|

|||||

|

610

|

230

|

9

|

13.2

|

21.64

|

1086

|

|||||

|

695

|

180

|

8

|

14.57

|

20.96

|

717

|

|||||

|

695

|

180

|

10

|

17.89

|

25.74

|

852

|

|||||

|

705

|

180

|

7.5

|

12.4

|

17.64

|

682

|

|||||

|

740

|

180

|

6

|

11.08

|

14.97

|

548

|

|||||

|

565

|

245

|

9

|

15.3

|

27.08

|

1042

|

|||||

|

290

|

240

|

7

|

6.1

|

21.03

|

1228

|

|||||

|

290

|

240

|

9

|

6.5

|

22.41

|

1462

|

|||||

|

290

|

240

|

11

|

7.9

|

27.24

|

1711

|

|||||

Friends, do you need the above specifications?

If not, We can also provide you with customized services,

Contact us for customized solutions for pultruded FRP products

Application

Styles of Fiberglass Pultrusions

Our regular colors include black, gray, red, orange, yellow, white, green and blue. And we can offer any other color you request. Also the unit length is selectable it could be from several millimetres to more than eleven meters.

With the development and experience in pultrusion for several years, we have more than 200 sets of mold for pultruding rods, tubes, channels and other standard profiles. Please see the specification we can supply. If you fail in finding the items you request, feel free to contact us.

We are experienced in custom product design and manufacturing. For a custom specification or need technical/design help? Contact our technical department.

About Us

Henan Zhongsheng Composite Materials Co.,Ltd (abbreviated as Henan Zosen Composite Material Co.,Ltd ) was estabilished in 1995, is a leading and professional manufacturer which dedicated to R&D and processing of FRP products, FRP pultrusion mould and releated products.

The Company is located in Xinxiang ,Henan ,covering an area of 18000 square meters and has over 200 employees, including 25 engineers, 28 senior technicians ,20 management and 138 skilled workers .The factory is equipped with 26 frp production lines and 35 sets of precision mold processing machines which reached auunal output of over 1800 tons of frp products.Our main products cover various of FRP profiles,such as channels, sections, angels , bars, rods, pipes, grids ,flanges, radoms, skylight plane, FRP insulated ladders , FRP fence etc.

They are widely used in transportation, electronic power, sewage treatment, aquaculture industry, sports equipment, automation equipment support, petrochemical and other fields. Moreover, we have advanced mold production workshop which could provide precision FRP pultrusion mould and SMC mould for ourself and other manufacturers.

Certifications

Packing &Deliery

FAQ

Q1: Are you Trading Company or Manufacturing Factory?

A: We are both manufacturer trading and company. We have our own factory, and we have better service of overseas customers. Welcome to send your inquiry!

Q2: I am interested in your products, could I get sample for free?

A: We can supply a few pieces FREE samples if we have some in stock, and you only need to pay the freight cost by yourself. Welcome to send your inquiry for FREE samples!

Q3: How about the Delivery time?

A: 10-15 days after receiving the deposit based on the MOQ. Normally, 30-35 days to finish the order for a 20ft container. Welcome to ask for the detailed delivery time according to your order quantity!

Q4: How can you guarantee the product quality?

A: Our whole production lines and products have been certified by ISO9001:2015, and it's been followed strictly. We also have the professional QC team, and each our package worker will be in charge of the final inspection according to the QC instruction before packing

Q5: What is about the payment terms.

A: Basically, the payment terms are T/T, L/C at sight. Western Union, Paypal, Moneygram, Alipay, Credit card are acceptable for sample order.

Q6: Can you do OEM for me?

A: We accept all OEM orders,just contact us and give me your design,we will offer you a reasonable price ASAP.

Hot Searches